Valve position indicator and valve position indicating system

A technology of indicators and valves, applied in the direction of valve devices, valve details, valve shell structures, etc., can solve the problem of outputting wrong signals when valves are open and closed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

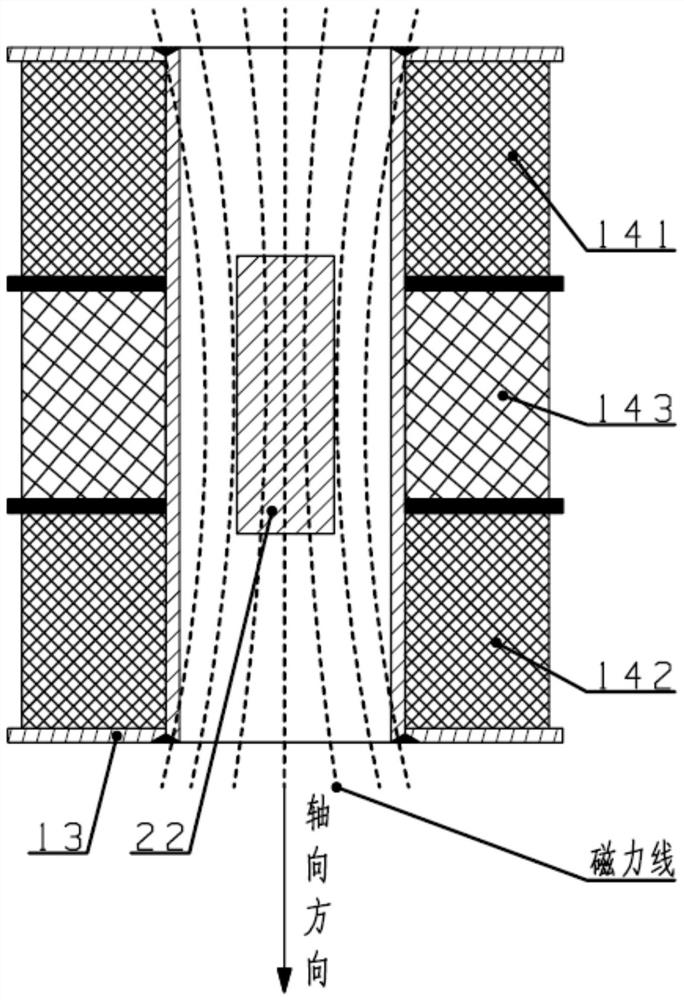

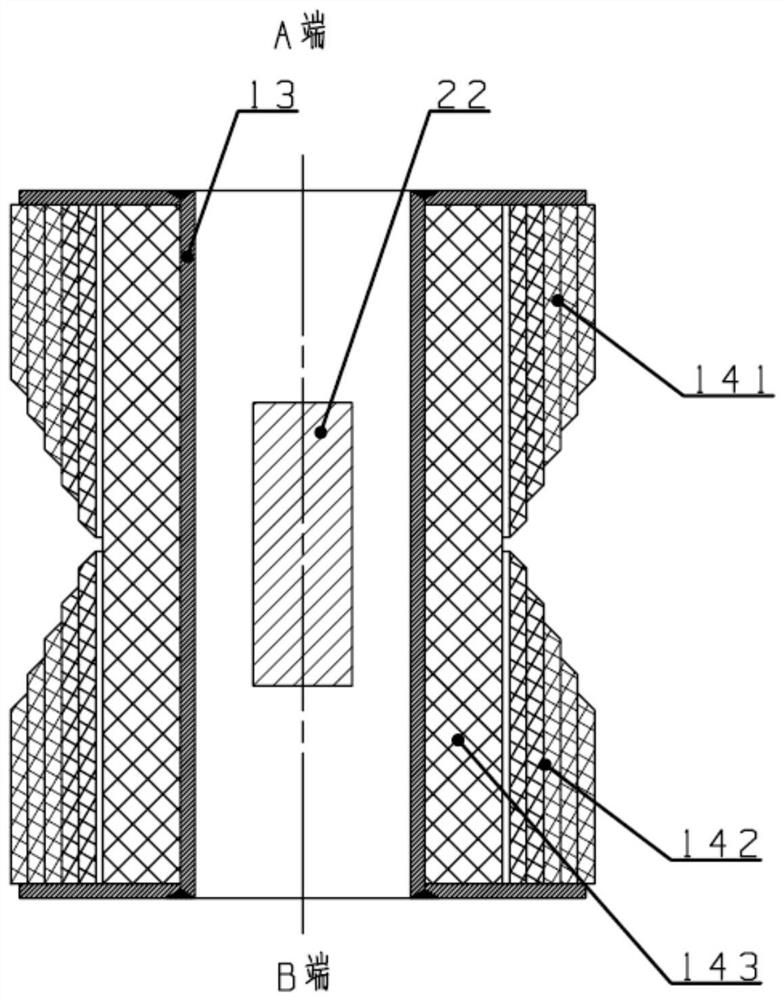

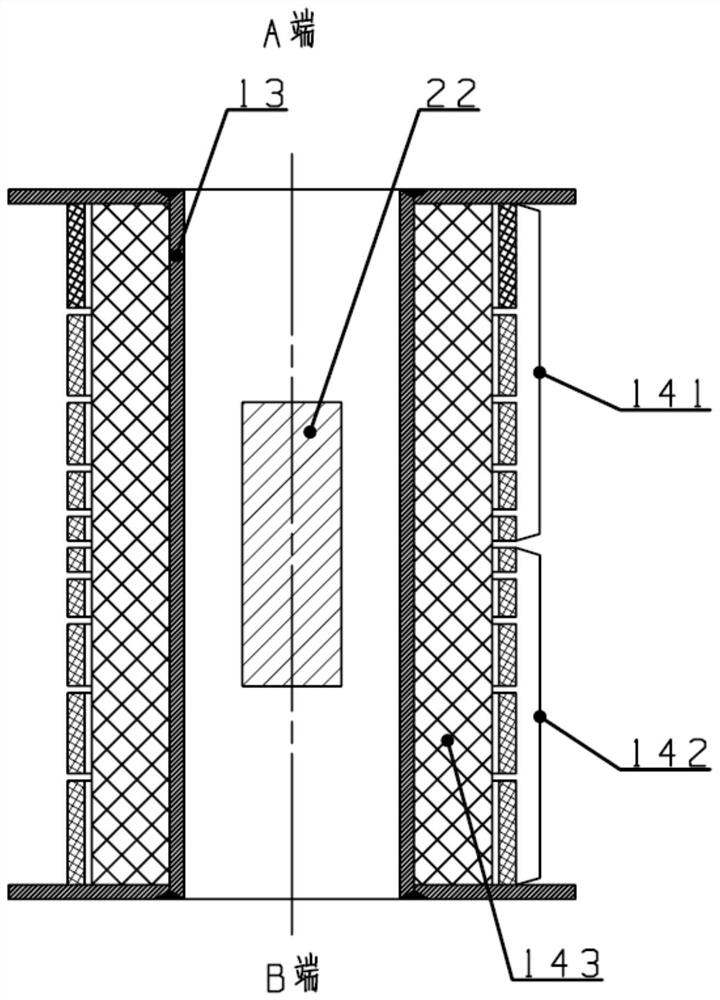

[0066] The valve position indicator includes the body structure of the valve position indicator 1, the body structure includes a continuous valve position signal sensing part, the continuous valve position signal sensing part includes a skeleton 13, a coil 14, and the coil 14 includes a primary coil 143 1. Secondary coil, it is characterized in that, described primary coil 143 is wound outside skeleton 13, and the quantity of described secondary coil is 2, and 2 secondary coils are wound on primary coil 143 simultaneously, wherein one secondary The number of turns of the coil increases along the midpoint of the axis of the skeleton 13 toward the end A of the skeleton 13 , and the number of turns of the other secondary coil increases along the midpoint of the axis of the skeleton 13 toward the end B of the skeleton 13 .

[0067] The above-mentioned technical solution can achieve the purpose of improving the measurement range and the strength of the measurement signal, thereby im...

Embodiment 2

[0107] A valve position indicating system,

[0108] like Image 6 As shown, it includes the above-mentioned valve position indicator 1 and cabinet 6. The cabinet 6 introduces the continuous valve position signal output by the continuous valve position signal sensing part from the valve position indicator 1 and the output signal of two magnetic control switch probes. Limit signal; the limit signals of the switching value output by the two magnetically controlled switch probes are the upper limit signal and the lower limit signal respectively, and the upper limit signal and the lower limit signal respectively represent the upper limit position and the lower limit position of the valve;

[0109] The continuous valve position signal is an analog signal, the upper limit signal and the lower limit signal respectively represent the standard current signal of 4mA and 20mA;

[0110]Cabinet 6 is equipped with a self-test early warning program: if the current continuous valve position s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com