Working face mining method

A mining method and working face technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as frequent safety accidents, tight mining continuity, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

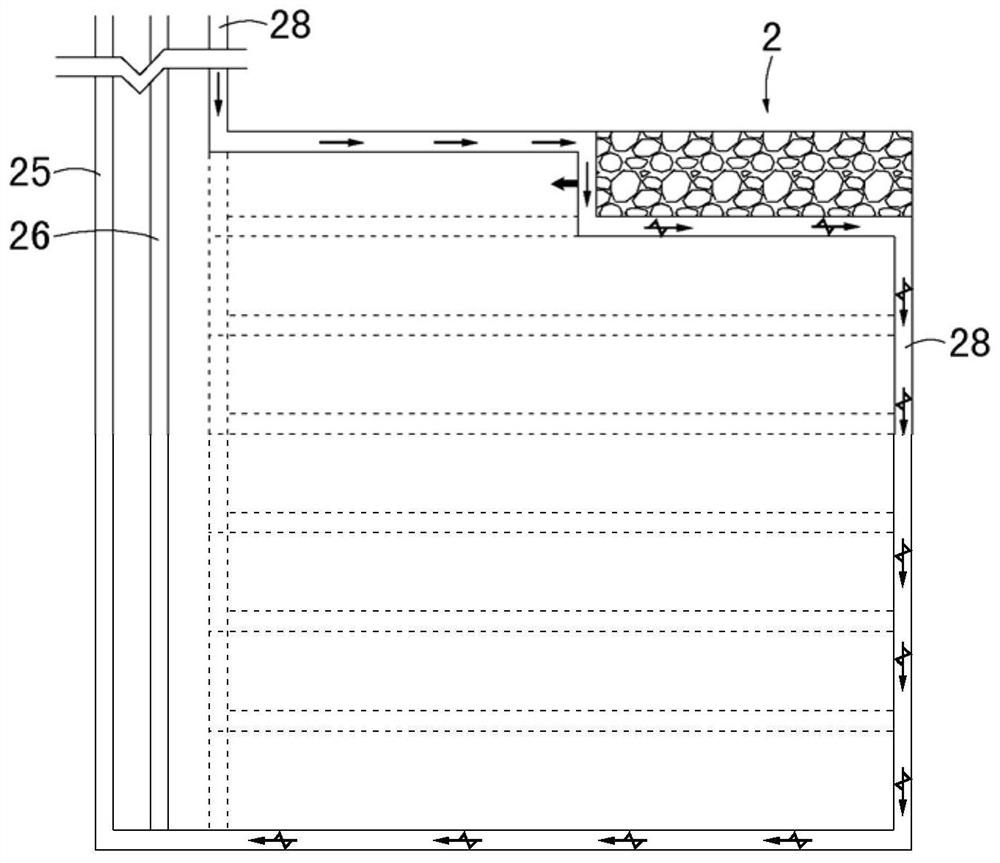

[0082] like figure 2 , image 3 As shown, in the mining method of double-side roadway retention in the embodiment of the present invention, the current mining area can include N working faces, and one side of the N working faces is directly provided with a return air roadway passage 29, a belt roadway passage 24 and a The passageway 28 of the track alley is connected to the wellhead to form a complete ventilation and transportation system. With the alternation of the working face, the three alleys extend to the new working face, and then connect with the new working face to form a complete transportation and return air system. The dotted line in the figure is the roadway formed in the subsequent sequence, and the solid line part is the roadway formed before or during the operation of the first mining face.

[0083] In this embodiment, the mining process of each working face includes:

[0084] Before mining, a cutout 31 is formed on the first mining face 20 to form the start...

Embodiment 2

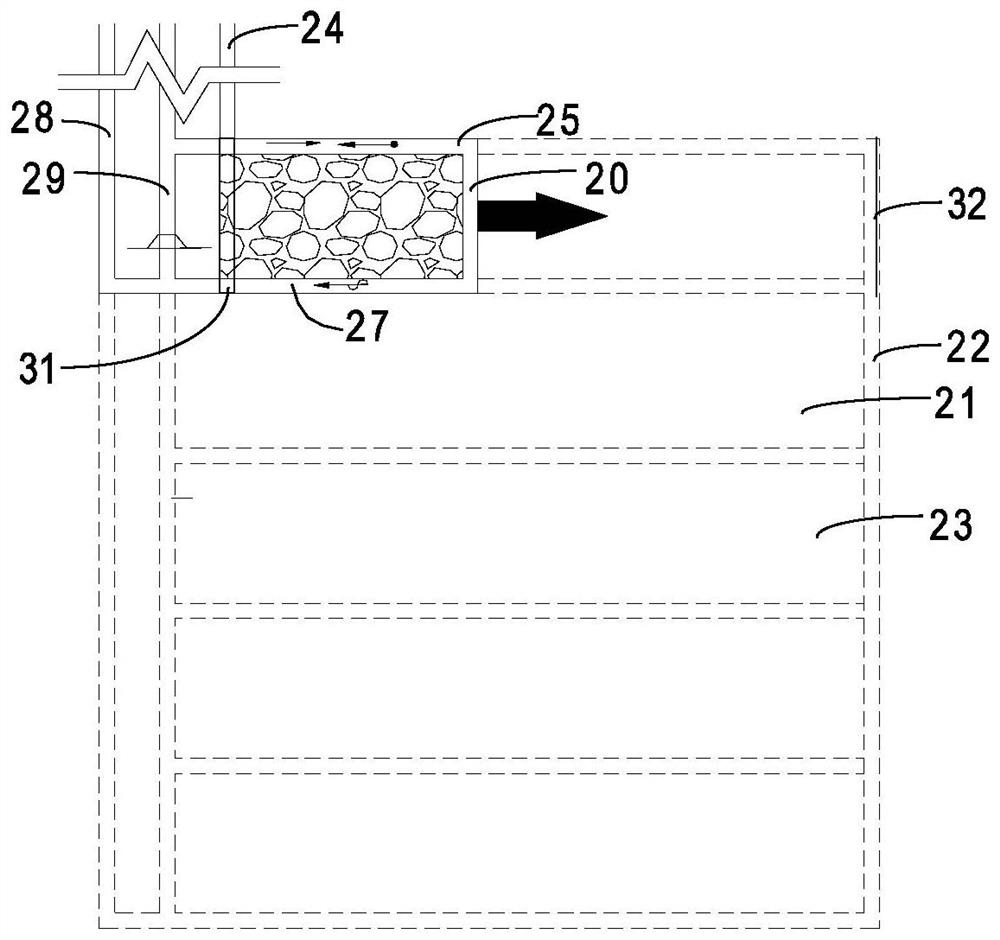

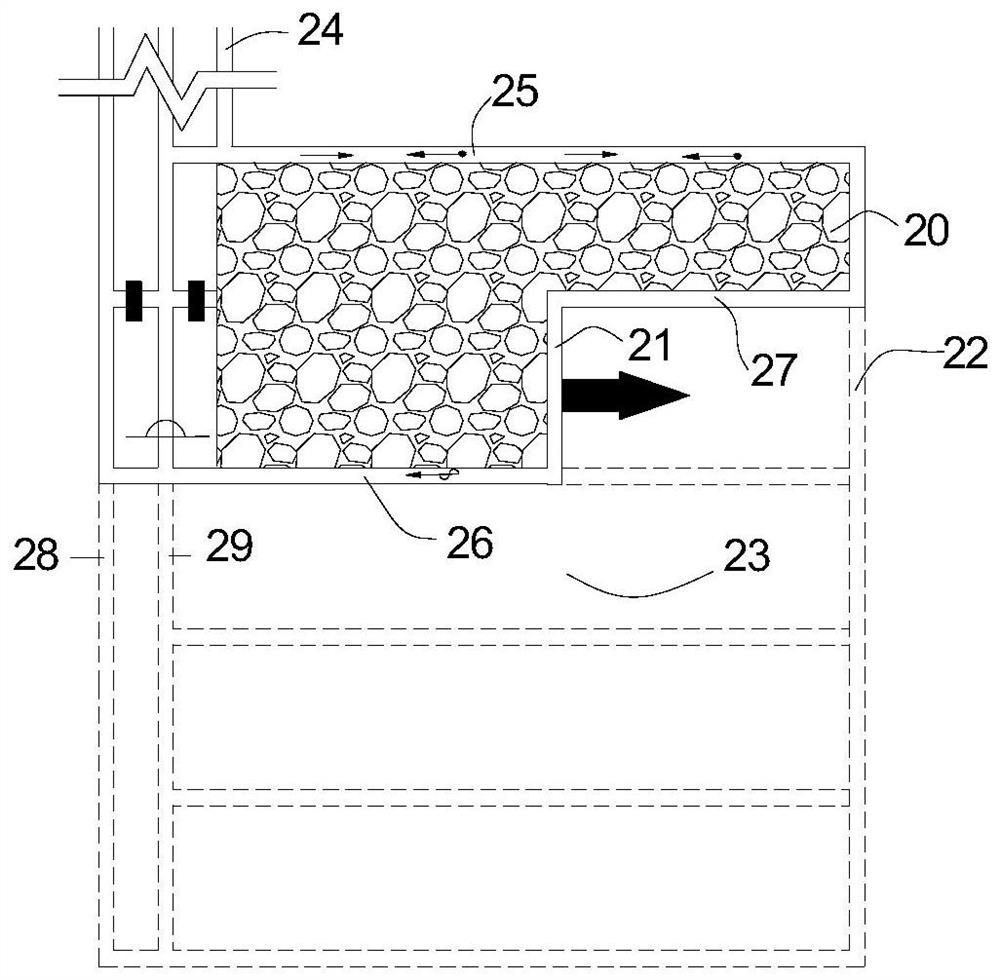

[0095] like Image 6 , Figure 7 As shown, the difference between embodiment two of the present application and embodiment one is that the working face is arranged along the belt alley passage 24 and the track alley passage 28. The process of retaining alleys on both sides of the face, sealing the goaf, and moving the working face. This arrangement no longer needs to excavate the parallel channel in advance, but forms the parallel channel after coal mining, thus greatly reducing the huge workload caused by the advance excavation of the parallel channel, greatly shortening the well construction period, and no longer Coal pillars need to be reserved to save resources, and the effect achieved is consistent with the expected effect of the present disclosure.

[0096] like Figure 8 , Figure 9 As shown, the difference between the embodiment two of the present application and the embodiment one is that the working face is arranged along the belt road passage 24 and the track ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com