Steel structure column installation structure

A technology for installing structures and steel structures, which is applied in the direction of building construction and construction, and can solve problems such as building collapse, inconvenient installation, and prone to tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

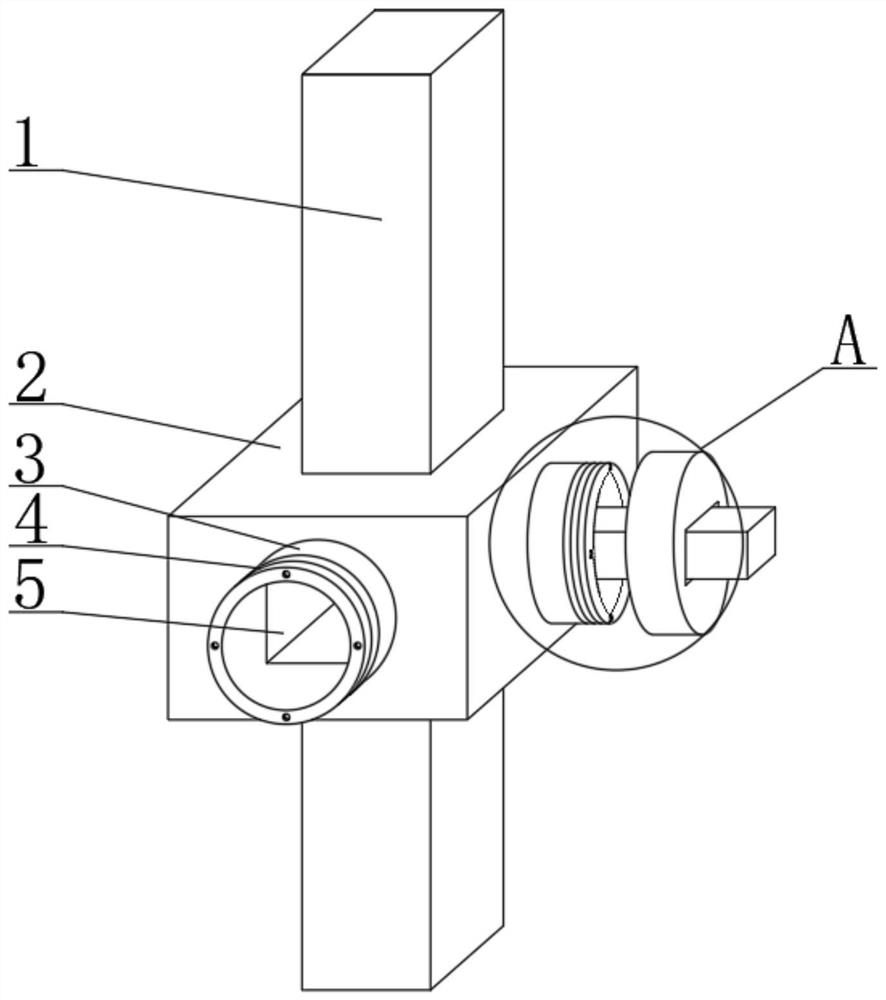

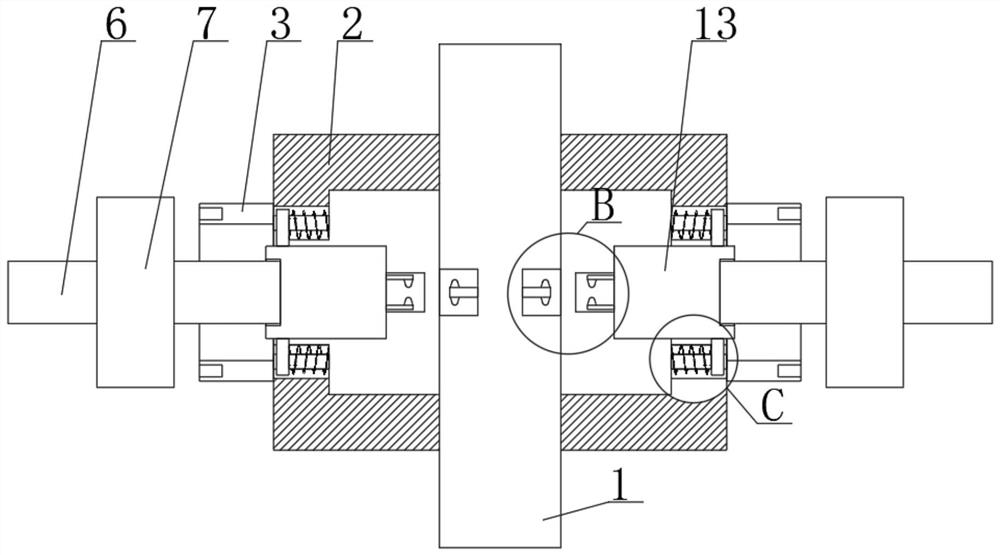

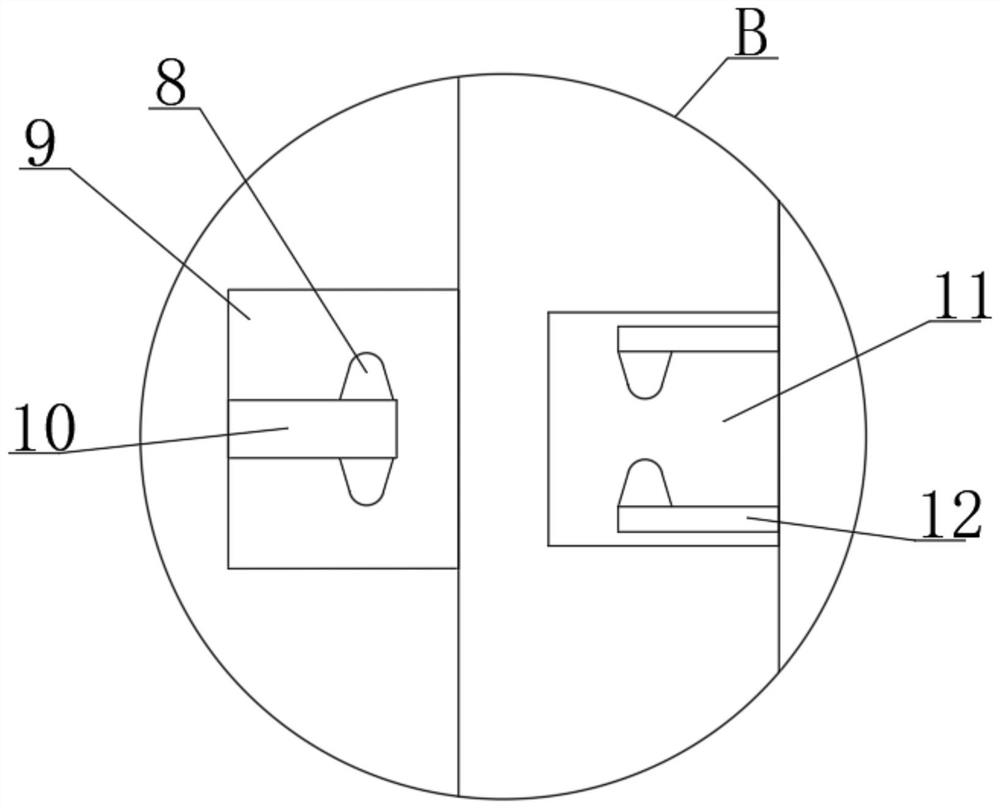

[0021] see Figure 1-5 , the present invention provides a technical solution: a steel column installation structure, comprising a steel column main body 1 and a horizontal steel column 6, the steel column main body 1 and the horizontal steel column 6 are vertically connected, and the steel column main body 1 is fixedly sleeved with a fixed The shell 2, the four sides of the fixed shell 2 are provided with connection holes 5, the inside of the connection hole 5 is movably connected with a movable block 13, the bottom end of the movable block 13 is connected with a snap block 11, and the inside of the snap block 11 is symmetrically connected with a connection Rods 12, the opposite surfaces of the two connecting rods 12 are connected with engaging teeth 8, the inside of the steel column main body 1 is provided with an engaging groove 9, the inside of the engaging groove 9 is connected with a fixed clamping rod 10, and the two sides of the fixed clamping rod 10 The engaging teeth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com