Excrement treatment system

A technology for manure treatment and port cleaning, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of small amount of separation, low efficiency, and slow separation speed at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

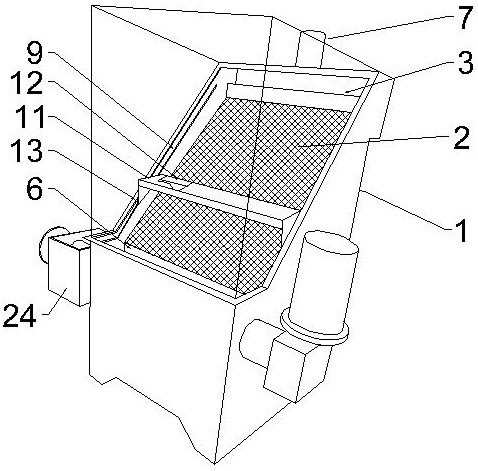

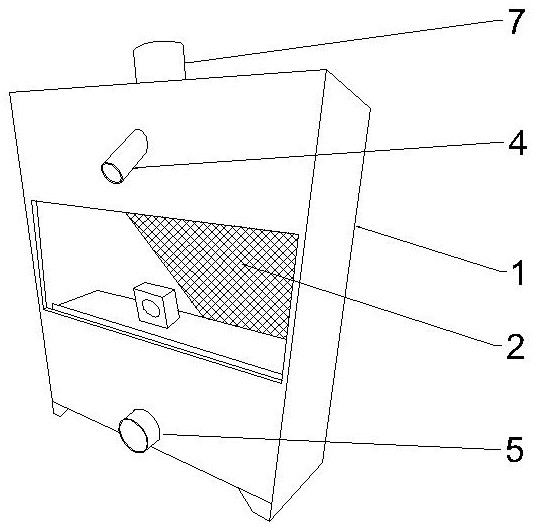

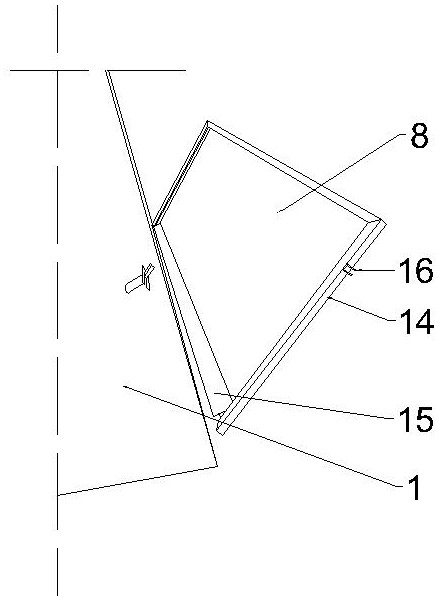

[0015] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 A kind of excrement treatment system described in this embodiment includes a box body 1, a filter screen 2 is fixed obliquely on the upper part of the box body 1, and a diversion groove 3 is installed in the box body 1 on the rear side of the higher end of the filter screen 2, and the box body 1 The feces inlet pipe 4 is arranged on the rear side of the upper part of the body 1, and the outlet of the feces inlet pipe 4 is located in the diversion tank 3. A liquid collection tank is provided in the box body 1 below the filter screen 2, and a drain pipe 5 is connected to one side of the liquid collection tank. , the outlet of the drain pipe 5 passes through the box body 1 to connect with the external pipeline, the box body 1 at the front side of the lower end of the filter screen 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com