Automobile maintenance tool

A technology for automobile maintenance and tools, which is applied in the direction of lifting devices, lifting frames, and parts of pumping devices for elastic fluids, etc. It can solve the problems of no better lifting effect and cannot be widely used, and achieves simple structure and convenient use , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

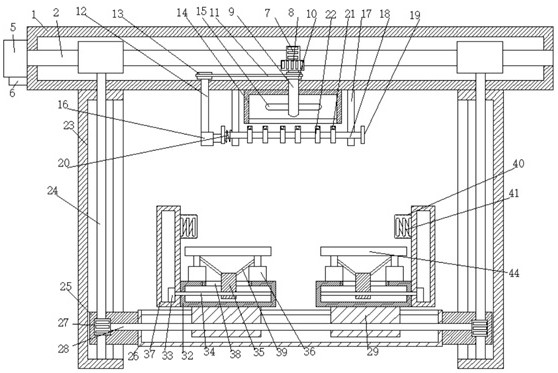

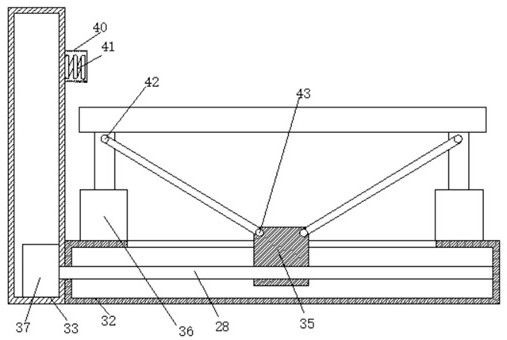

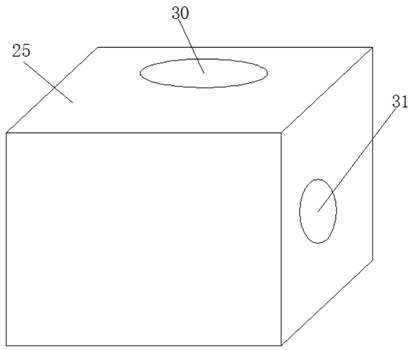

[0028] refer to Figure 1-5 , a kind of automobile maintenance tool, comprises top base 1, and the bottom of top base 1 is fixedly connected with two supporting columns 23, and one side of two supporting columns 23 is provided with second elongated hole, and the two supporting columns 23 rotate respectively Two second screw rods 24 are connected, and one end of the two second screw rods 24 is provided with a connecting block 25, and the tops of the two connecting blocks 25 are provided with a first threaded hole 30, and one side of the two connecting blocks 25 is A second threaded hole 31 is provided, and two first threaded holes 30 are threadedly connected with two second screw rods 24 respectively, and one end of the two connection blocks 25 is fixedly connected with the same base 26, and the base 26 is rotationally connected with a third Screw rod 28, the two ends of the 3rd screw rod 28 are all fixedly sleeved with the 3rd gear 27, and two 3rd gears 27 are respectively pos...

Embodiment 2

[0039] refer to Figure 1-5 , a kind of automobile maintenance tool, comprises top seat 1, and the bottom of top seat 1 is welded and connected with two supporting columns 23, and one side of two supporting columns 23 is all provided with the second long hole, and the two supporting columns 23 rotate respectively Two second screw rods 24 are connected, and one end of the two second screw rods 24 is provided with a connecting block 25, and the tops of the two connecting blocks 25 are provided with a first threaded hole 30, and one side of the two connecting blocks 25 is A second threaded hole 31 is provided, and two first threaded holes 30 are threadedly connected with two second screw rods 24 respectively, and one end of the two connecting blocks 25 is welded with the same base 26, and the base 26 is rotationally connected with a third Screw rod 28, the two ends of the third screw rod 28 are all welded with the third gear 27, and the two third gears 27 are respectively located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com