Electric booster for vehicle

A booster and electric technology, which is applied in the direction of brakes, vehicle components, transmissions, etc., can solve the problems of increased size, unfavorable noise, and unfavorable layout of electric boosters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, an electric booster for a vehicle will be described below through various examples of embodiments with reference to the accompanying drawings. It should be noted that the drawings are not drawn to precise scale and may be exaggerated in thickness of lines or size of components for convenience and clarity of description only. Also, the terms as used herein are defined by considering the functions of the present invention, and may be changed according to user's or operator's habit or intention. Therefore, definitions of terms should be made according to the overall disclosure set forth herein.

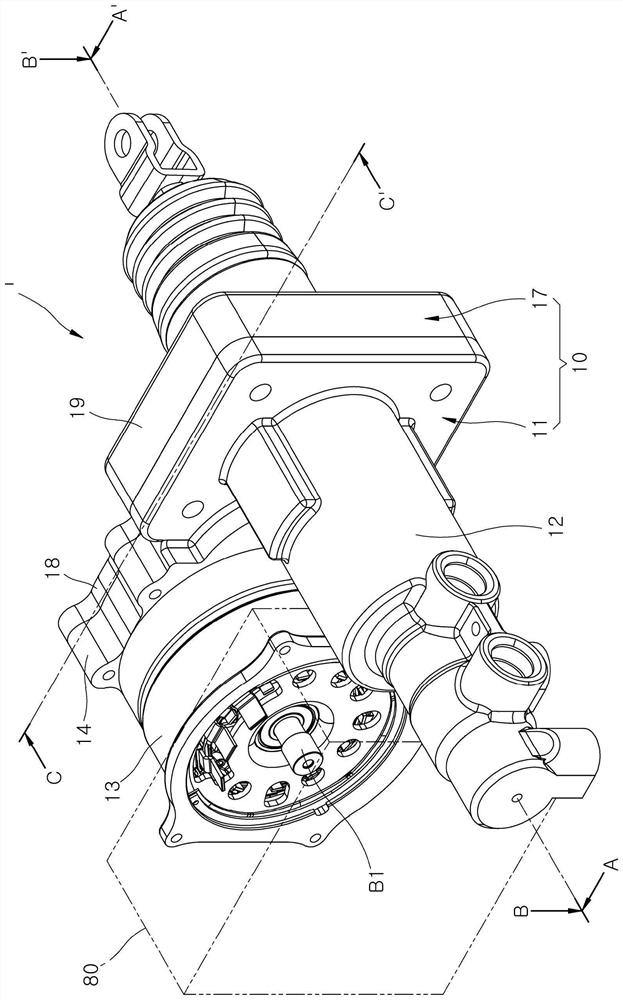

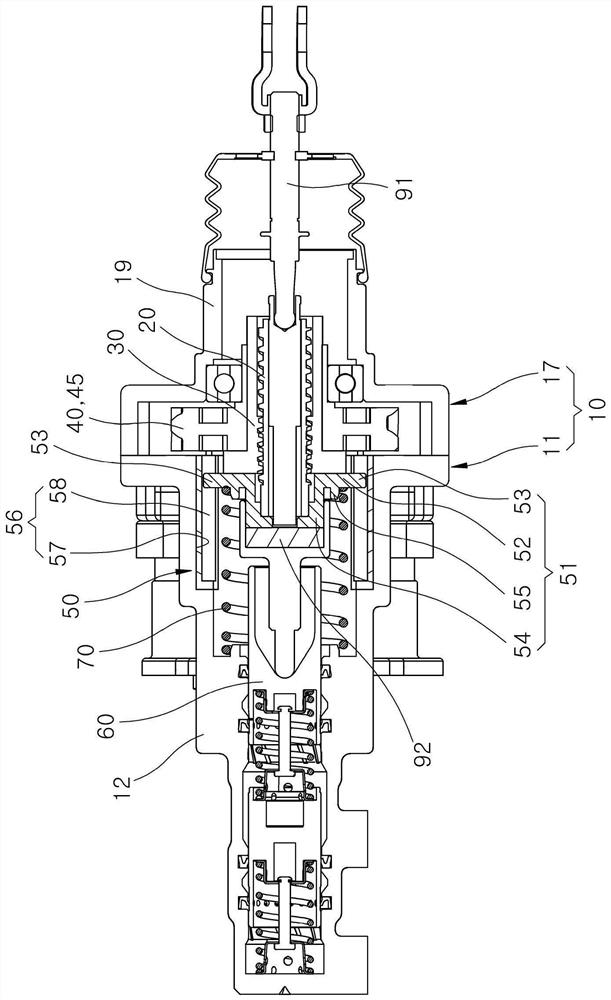

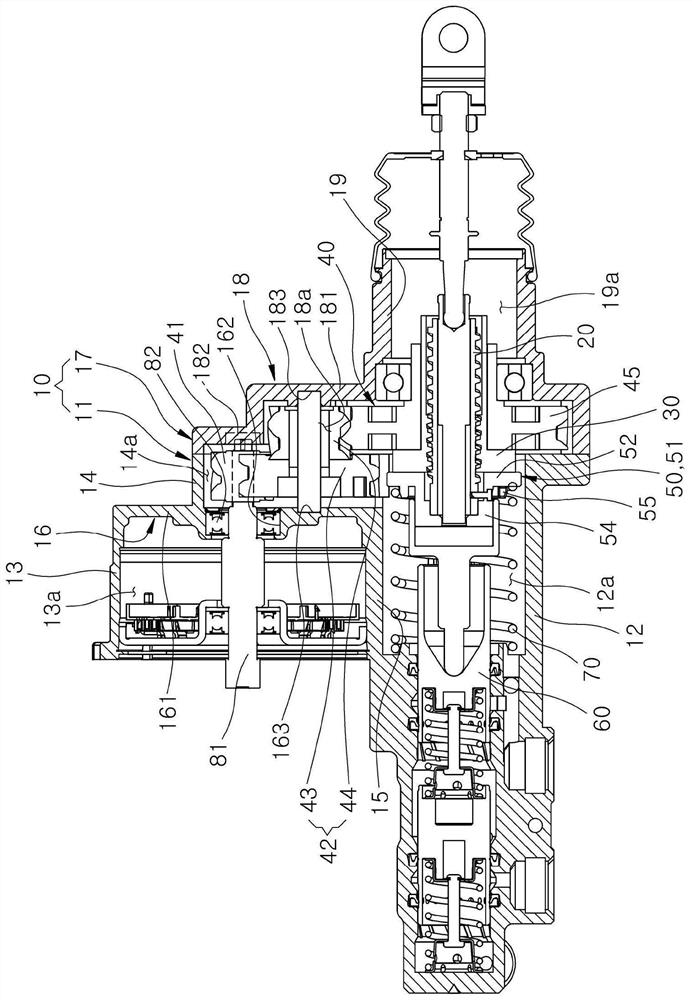

[0042] figure 1 is a perspective view schematically showing an illustration of an example of an electric booster for a vehicle according to an embodiment of the present disclosure, and figure 2 is along figure 1 A cross-sectional view taken on line A-A'.

[0043] refer to figure 1 and figure 2 , an electric booster 1 for a vehicle according to an embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com