Vegetable transplanter

A technology for transplanting machines and vegetables, applied in the field of transplanting machines, can solve the problems of incomplete planting, difficulty in planting of vegetable transplanting machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

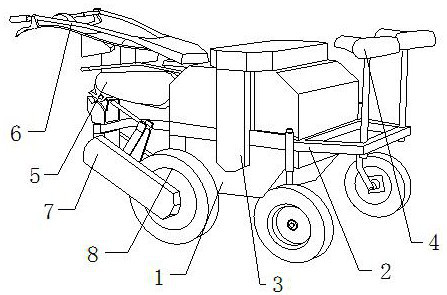

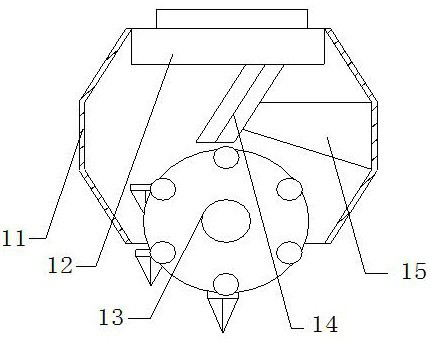

[0028] Such as Figure 1-Figure 5 Shown:

[0029] The invention provides a vegetable transplanting machine, its structure includes a transplanting machine case 1, a support frame 2, a fixed plate 3, a seat 4, a driving machine 5, a control handle 6, a connecting rod 7, and a moving wheel 8. The control handle 6 is electrically connected to the top of the driving machine 5 and connected to the transplanting machine box 1, the moving wheel 8 is movably engaged at the bottom of the transplanting machine box 1, and the connecting rod 7 is bolted between the driving machine 5 and the moving wheel 8 , the seat 4 is welded and connected to the rightmost end of the support frame 2, the fixed plate 3 is embedded and connected to the side of the transplanting case 1, and the transplanting case 1 is nested and connected inside the support frame 2. The cabinet 1 mainly includes a cabinet 11, a storage platform 12, a planter 13, a seedling separating device 14, and a fixed block 15. The s...

Embodiment 2

[0035] Such as Figure 6-Figure 9 Shown:

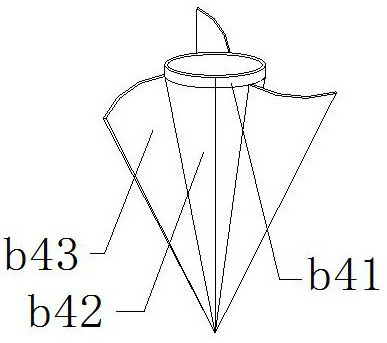

[0036]The present invention provides a vegetable transplanting machine. The planting machine 13 mainly includes a shaft rod 131, an auxiliary piece 132, a secondary shaft 133, an adjustment wheel 134, and a planting device 135. The auxiliary piece 132 is embedded and connected to the On both sides of the shaft center rod 131, the auxiliary shaft rod 133 is movably engaged with the outermost periphery of the auxiliary piece 132, the adjustment wheel 134 is connected with the auxiliary shaft rod 133, and the insertion device 135 is movably engaged with the auxiliary shaft rod 133 Outside and between the auxiliary sheets 132, the planting device 135 is provided with six places in total, and is evenly installed on the outermost side of the auxiliary sheet 132, so that the planter b4 can be in better contact with the soil, so as to perform better The planting work, the adjustment wheel 134 can avoid the angle deviation of the planter b4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com