Oil-gas pressure accompanying control device for diaphragm compressor and oil-gas pressure accompanying control system for diaphragm compressor

A diaphragm compressor and control device technology, applied in the field of compressors, can solve problems such as large oil pressure difference, increased system failure rate, and reduced diaphragm life, so as to reduce failure rate, system complexity, and failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

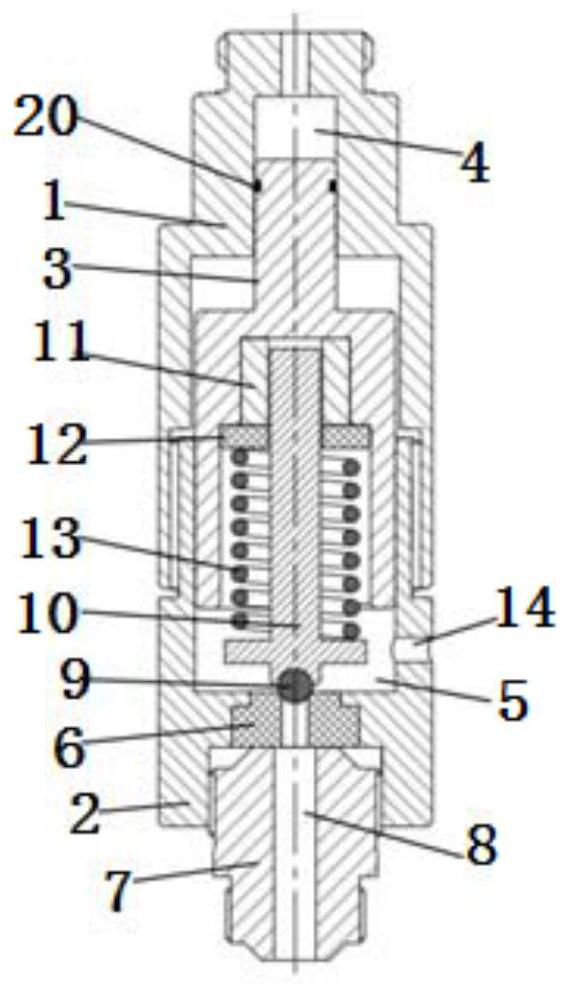

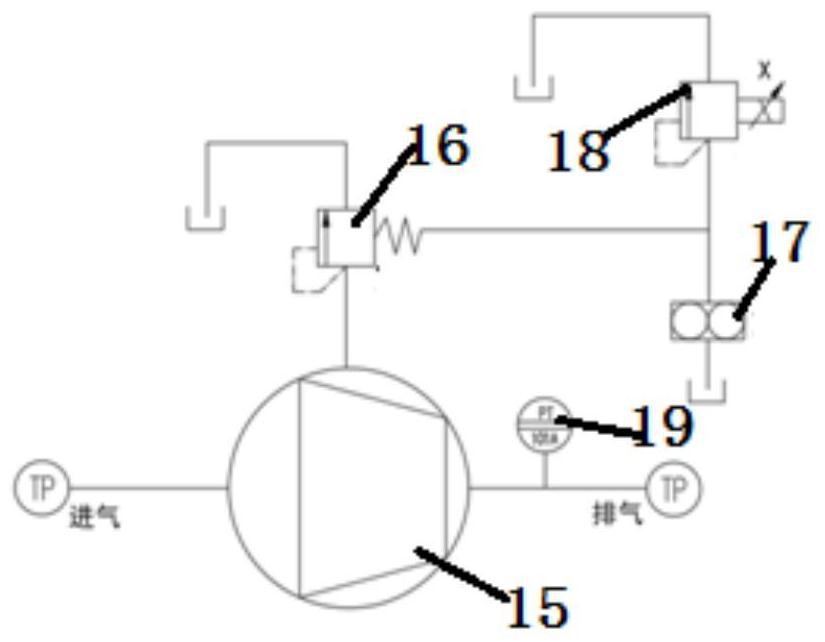

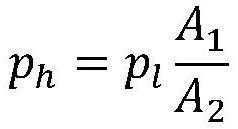

[0049] The high-pressure diaphragm compressor oil pressure accompanying control system includes a diaphragm compressor 15 , a pressure transmitter 19 , a proportional overflow valve 18 , and a diaphragm compressor oil pressure accompanying control device 16 . The pressure transmitter 19 measures the discharge pressure value of the diaphragm compressor 15 and converts it into an electrical signal and transmits it to the control terminal of the proportional relief valve 18. The proportional relief valve 18 controls the displacement of its own proportional electromagnet according to the signal of the discharge pressure. Adjust its own overflow pressure to control the outlet pressure of the gear pump 17, so that the oil pressure at the outlet of the gear pump 17 and the exhaust pressure can follow up. The oil pressure at the outlet of the gear pump 17 is generally low, and it is used as low-pressure oil to supply the diaphragm compressor The oil pressure follows the low pressure ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com