Automatic stacking device based on wooden floor stacking

An automatic stacking and floor technology, applied in the cleaning method using tools, stacking, transportation and packaging of objects, etc., can solve the problems of time-consuming, reducing the quality of the working environment, and increasing the labor force of the staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

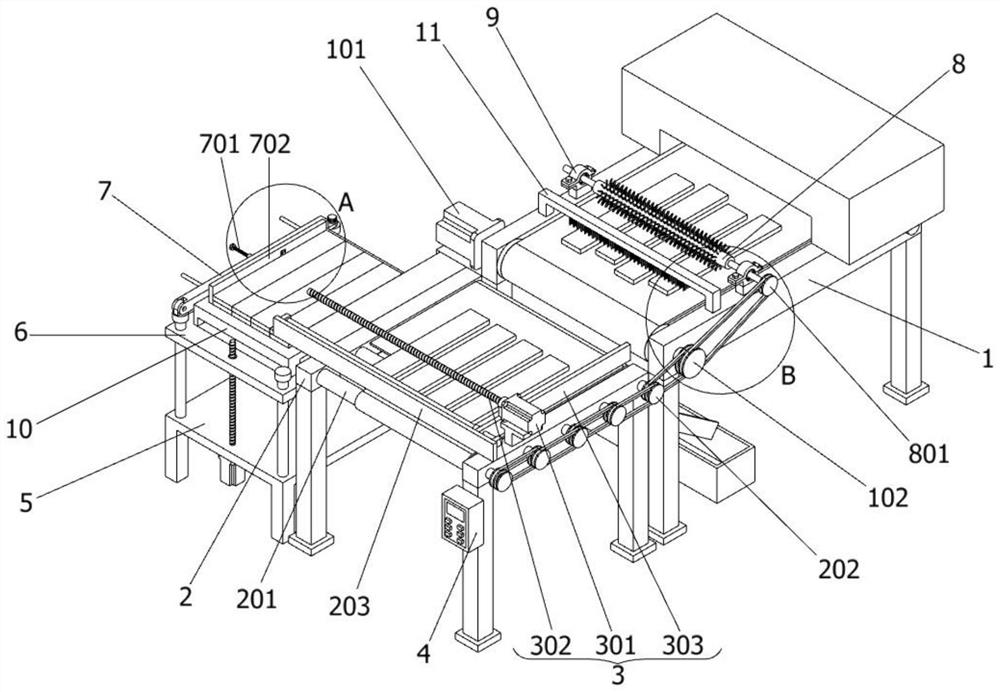

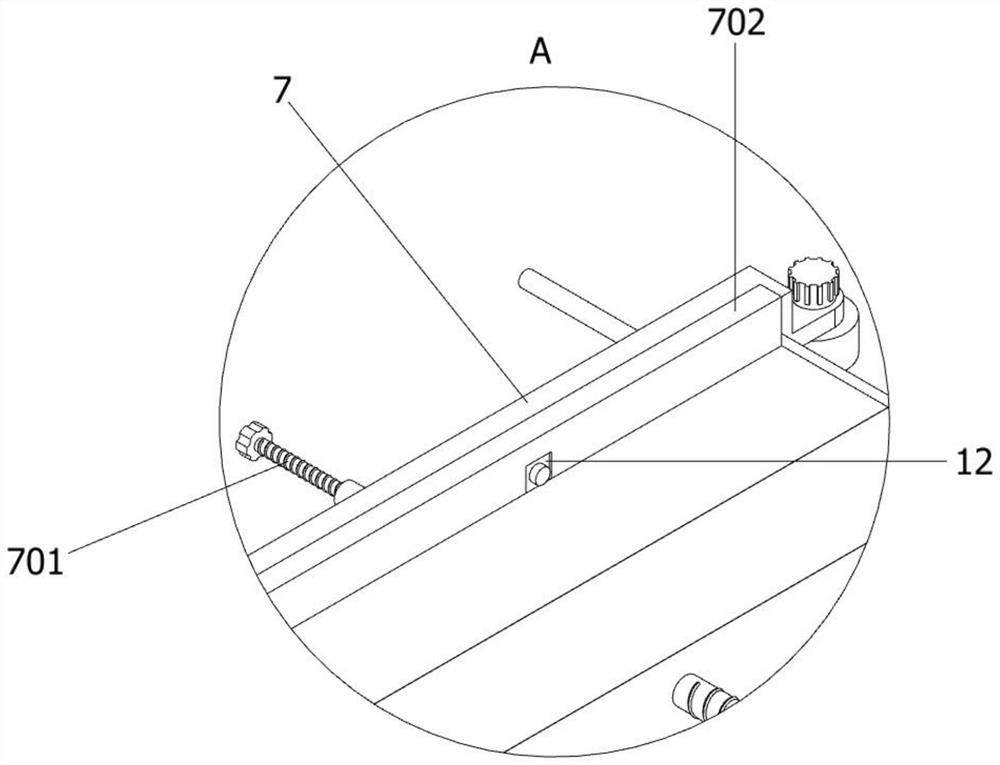

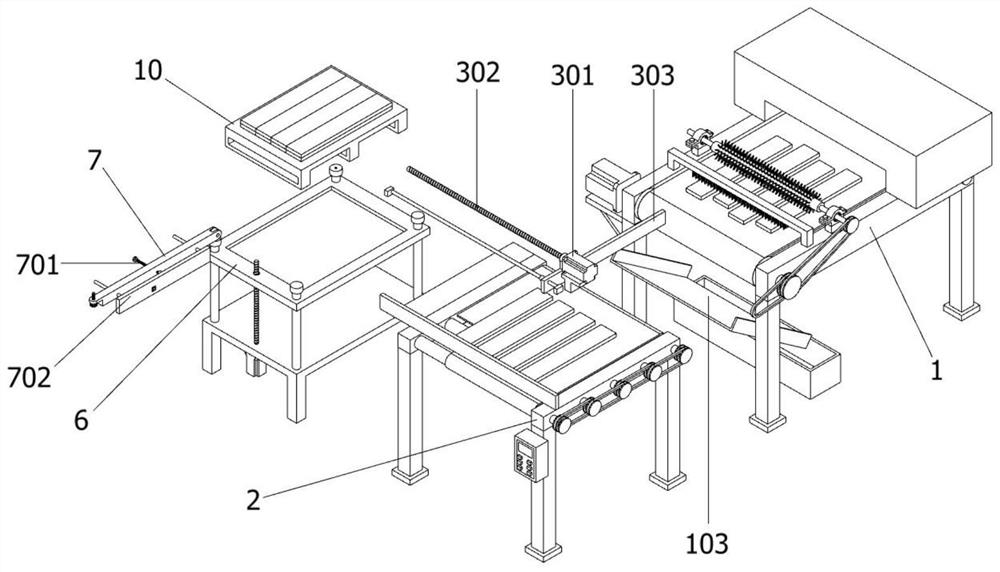

[0033] as attached figure 1 To attach Figure 9 Shown:

[0034] The present invention provides an automatic stacking device based on wooden floor stacking, including: a transmission frame 1, an alignment mechanism 2 is provided on the front side of the transmission frame 1, and the alignment mechanism 2 includes a transmission roller 201, a double-groove driven pulley 202, alignment baffle plate 203 and rectangular plate 204, the inside of the upper part of the alignment mechanism 2 is uniformly rotated and connected with five transmission rollers 201, and the outer peripheral surface of the five transmission rollers 201 is connected with a conveyor belt, and each transmission roller 201 shaft The right end is provided with a double-groove driven pulley 202, and every two adjacent double-groove driven pulleys 202 are connected by a belt drive, and the front side of the upper end of the alignment mechanism 2 is provided with an alignment baffle plate 203, and The upper left e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com