Automatic labelling machine for label

A labeling machine, labeling technology, applied in the direction of labeling machine, labeling, packaging, etc., can solve the problems of high cost, affecting production efficiency, difficult to operate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

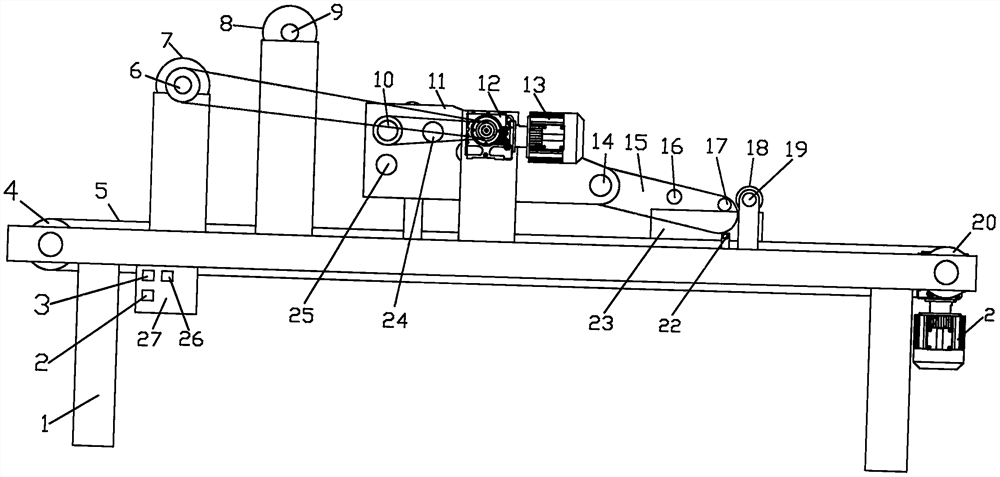

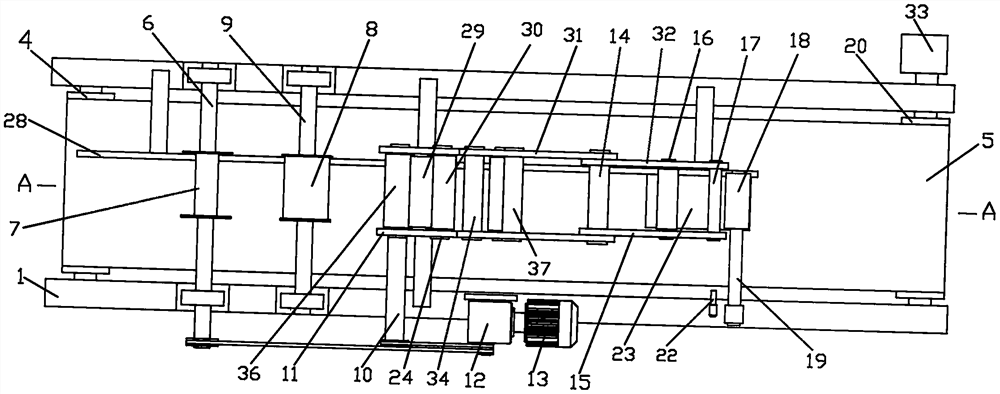

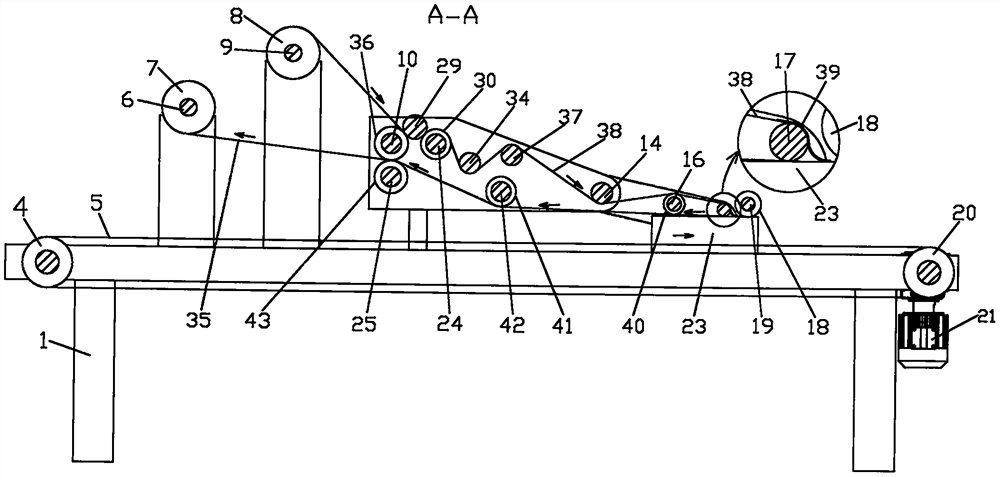

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as Figure 1-Figure 3 As shown, the label automatic labeling machine includes a frame 1, and the two ends of the frame 1 are rotatably connected with a driving driving roller 4 and a driving passive roller 20, and the driving driving roller 4 and the driving passive roller 20 drive the conveyor belt 5 to rotate; the driving driving roller 4 It is connected with the transmission reduction box 33, and the transmission reduction box 33 is connected with the transmission motor 21; the frame 1 is connected to the winding roller shaft 6, the unwinding roller shaft 9, and the front side plate 11, the front two Side plate 31, pulling reduction box 12, photoelectric switch 22, flattening roller shaft 19, fixed receiving roll 7 on winding roller shaft 6; unwinding roller 8 fixed on unwinding roller shaft 9, unwinding roller 8 Wrapping the label tape 38; the front si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com