Soft bag filling device

A filling device and soft bag technology, applied in the field of automatic packaging, can solve the problems of large workload of filling varieties, unsuitable guiding structure, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

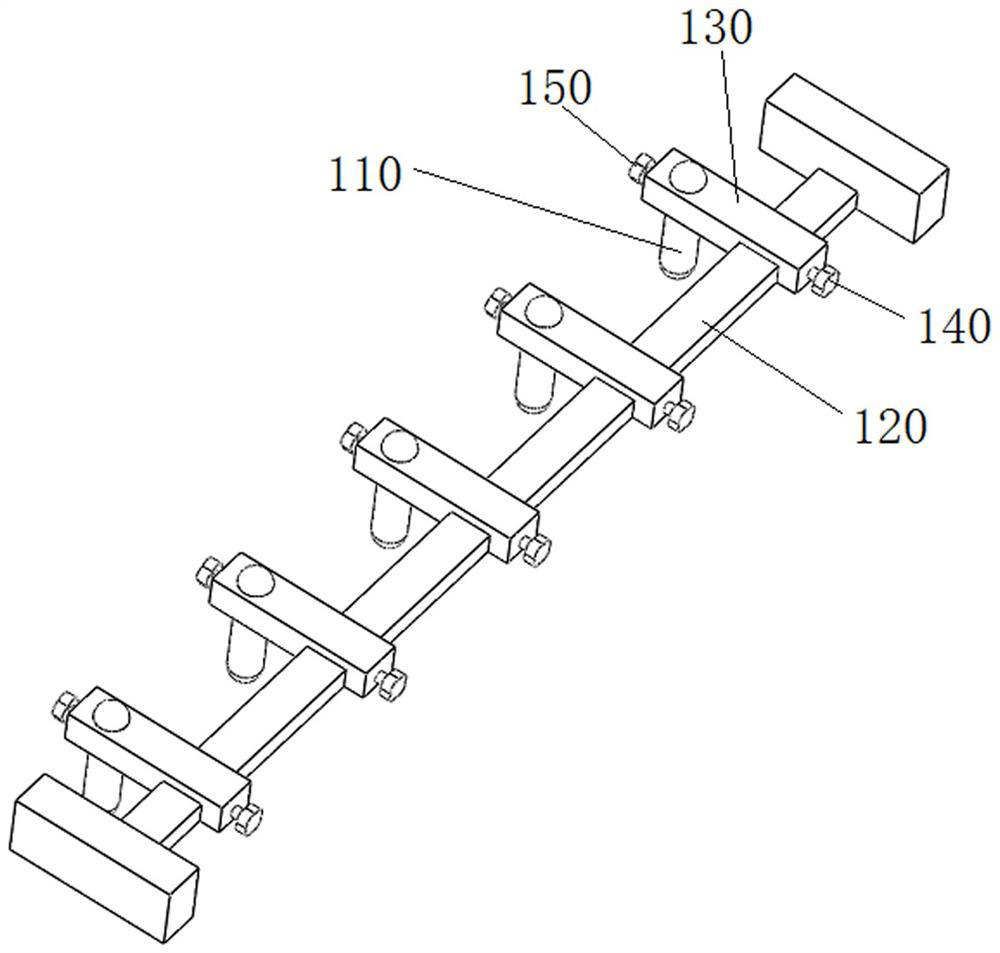

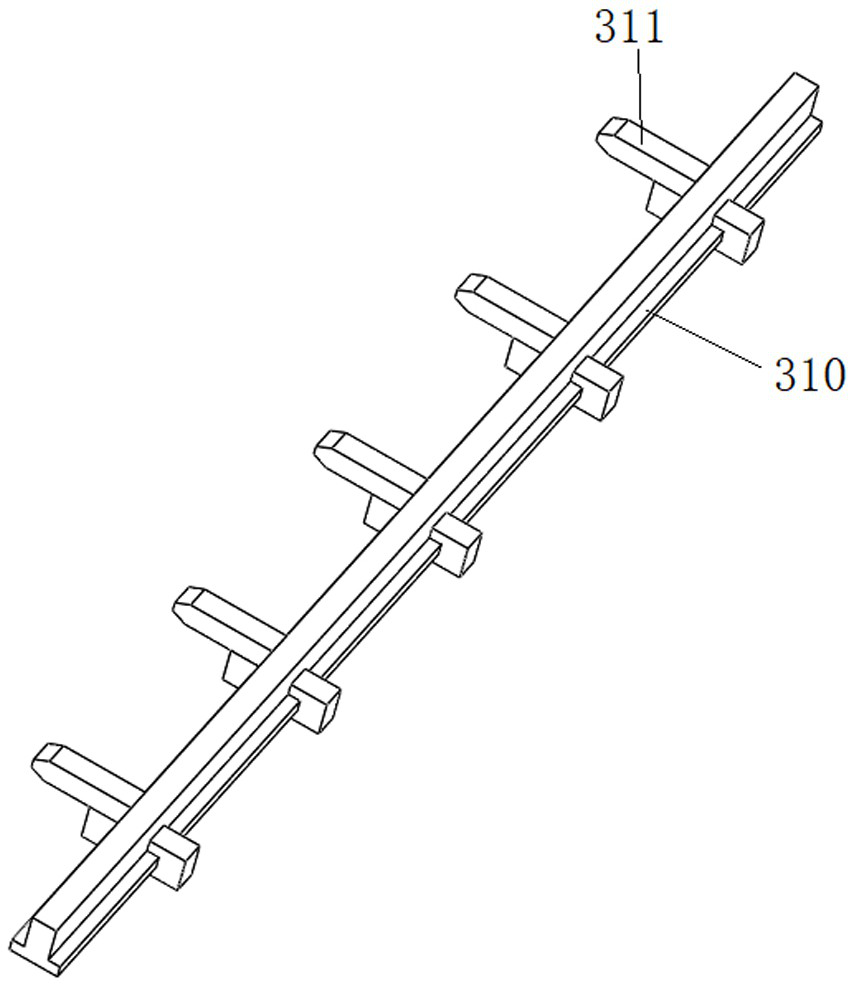

[0029] In the Chinese invention patent application for a soft bag packaging method and filling device (application number CN202010105770.8), a new filling device is disclosed that can meet the filling needs of multi-package bags, but it is difficult in the actual production process. When in use, limited by the structure of the guide plate and the filling through hole, it can only meet the multi-bag filling requirements of some combined pesticide products (each single bag is mostly composed of the same form of ingredients and the filling volume is not much different). And once the size of the filling head is large or the difference between each filling head is large, the guiding structure in the existing device is not suitable. At the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com