Automatic release agent clearing and spraying equipment for shield segment mould

A shield segment and automatic cleaning technology, which is applied to auxiliary forming equipment, cleaning methods using tools, injection devices, etc., can solve the problems of reduced precision, low efficiency, and shield segment defects, so as to reduce production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

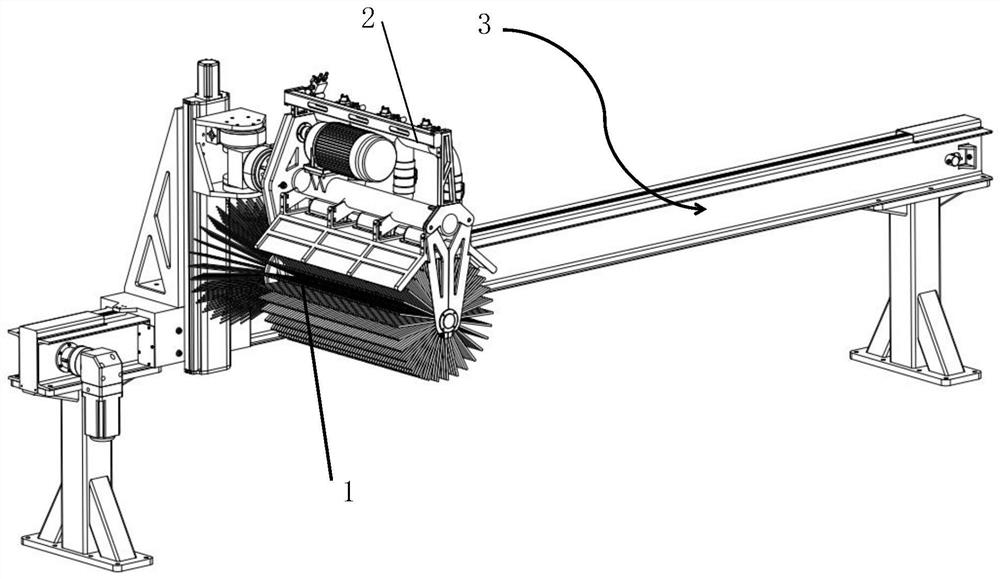

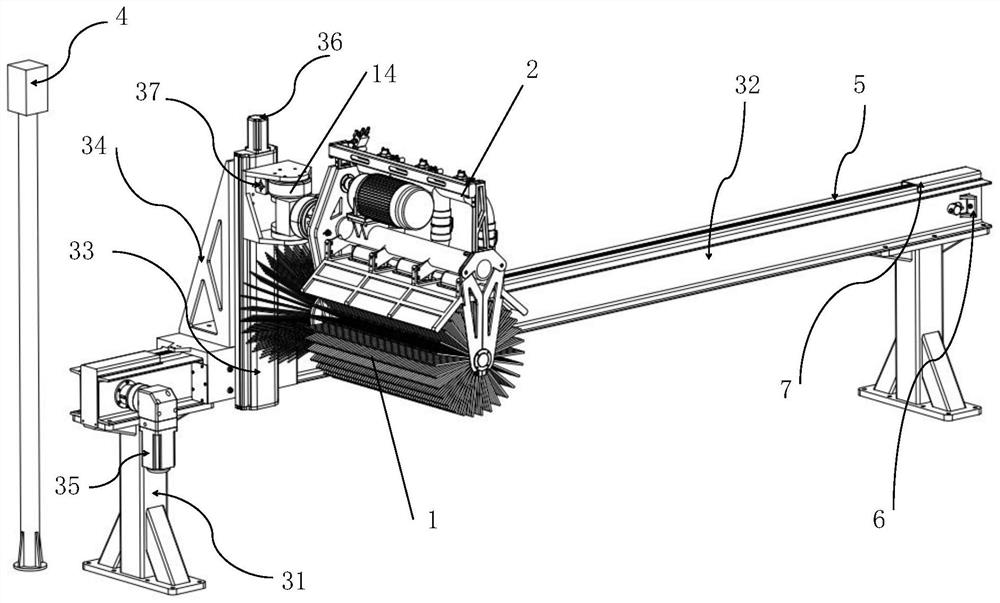

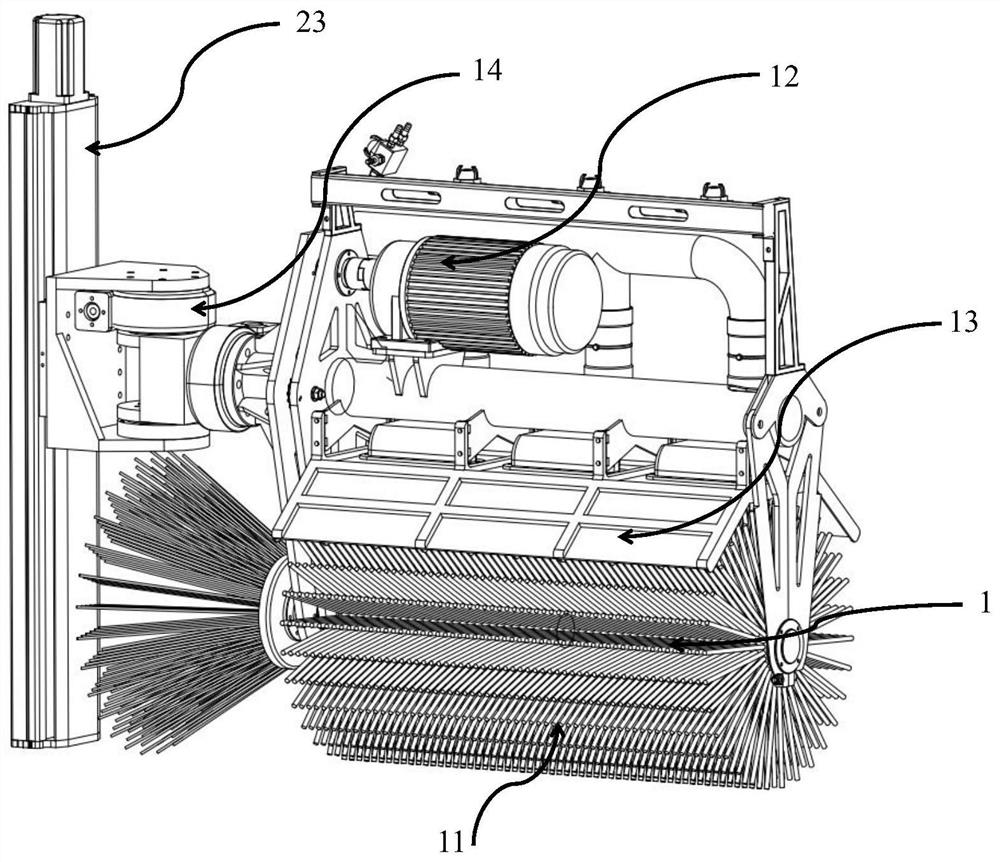

[0030] see Figure 1 to Figure 5 , the present embodiment includes a control system, a cleaning mechanism 1, a spraying mechanism 2 and a moving mechanism 3 for providing multi-dimensional action, the cleaning mechanism 1 is installed on the moving mechanism 3, the spraying mechanism 2 is installed on the cleaning mechanism 1, and the control The system is respectively connected with the cleaning mechanism 1, the spraying mechanism 2 and the moving mechanism 3, and by controlling the cleaning mechanism 1, the spraying mechanism 2 and the moving mechanism 3, the automatic cleaning of the shield segment mold and the automatic spraying of the release agent are realized;

[0031] The moving mechanism 3 includes a bracket 31, an X-direction movement module 32 and a Z-direction movement module 33. The lower end of the bracket 31 is fixed on the ground, the upper end of the bracket 31 is provided with an X-direction movement module 32, and the Z-direction movement module 33 is connect...

Embodiment 2

[0048] see Figure 1 to Figure 5 , the present embodiment includes a control system, a cleaning mechanism 1, a spraying mechanism 2 and a moving mechanism 3, the cleaning mechanism 1 is installed on the moving mechanism 3, the spraying mechanism 2 is installed on the cleaning mechanism 1, and the control system is respectively associated with the cleaning mechanism 1, The spraying mechanism 2 is connected with the moving mechanism 3, and by controlling the cleaning mechanism 1, the spraying mechanism 2 and the moving mechanism 3, the automatic cleaning of the shield segment mold and the automatic spraying of the release agent are realized;

[0049] The moving mechanism 3 includes a bracket 31, an X-direction movement module 32 and a Z-direction movement module 33. The lower end of the bracket 31 is fixed on the ground, the upper end of the bracket 31 is provided with an X-direction movement module 32, and the Z-direction movement module 33 is connected to the X-direction moveme...

Embodiment 3

[0061] see Figure 1 to Figure 5 , the present embodiment includes a control system, a cleaning mechanism 1, a spraying mechanism 2 and a moving mechanism 3 for providing multi-dimensional action, the cleaning mechanism 1 is installed on the moving mechanism 3, the spraying mechanism 2 is installed on the cleaning mechanism 1, and the control The system is respectively connected with the cleaning mechanism 1, the spraying mechanism 2 and the moving mechanism 3, and by controlling the cleaning mechanism 1, the spraying mechanism 2 and the moving mechanism 3, the automatic cleaning of the shield segment mold and the automatic spraying of the release agent are realized;

[0062] The moving mechanism 3 includes a bracket 31, an X-direction movement module 32 and a Z-direction movement module 33. The lower end of the bracket 31 is fixed on the ground, the upper end of the bracket 31 is provided with an X-direction movement module 32, and the Z-direction movement module 33 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com