High-precision intelligent periodic-rolling rolling machine for metal seamless tube material

A seamless tube, high-precision technology, used in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as poor tube quality, scratches, slubs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

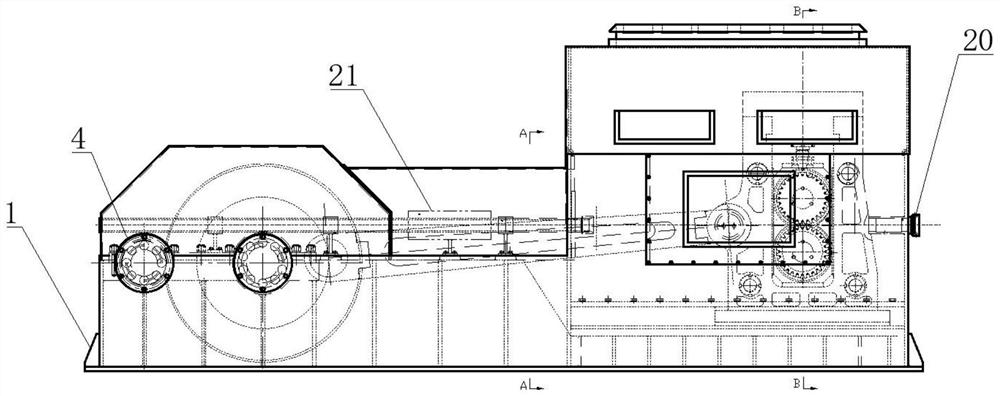

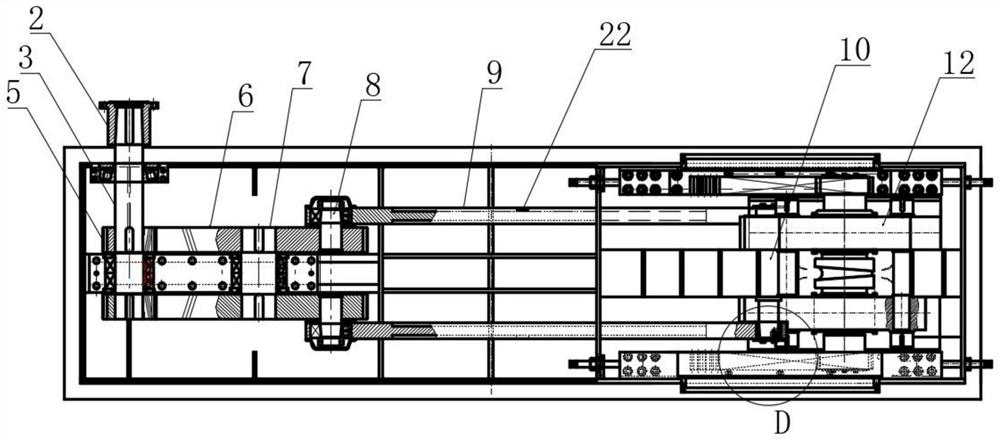

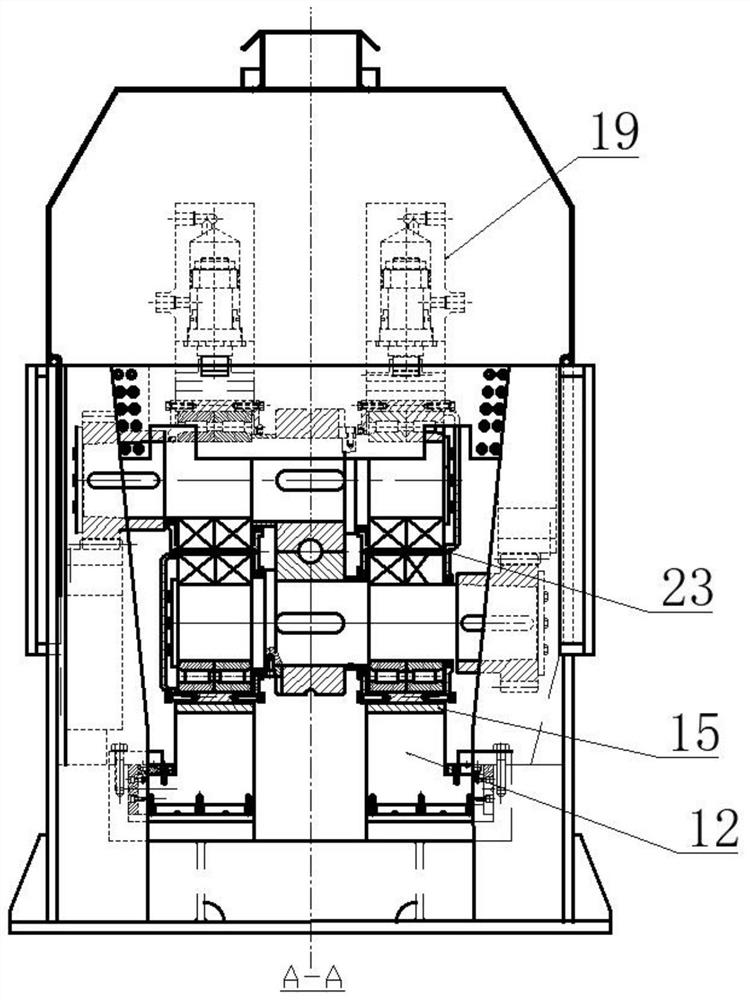

[0023] Such as Figure 1 to Figure 6As shown, an intelligent rolling mill for periodical rolling of high-precision metal seamless pipes includes a main body 1 and a power input device, the power input device is connected to a power input shaft 3 through a coupling 2, and the power input shaft 3 is installed In the No. 1 bearing seat 4 on the left side of the main body 1, two active "herringbone" gears 5 are arranged on the power input shaft 3, and the two active "herringbone" gears 5 mesh with a driven "Herringbone" large gear 6, the driven "Herringbone" large gear 6 is installed on the gear shaft 7, and the gear shaft 7 is rotatably installed on the main body 1, and the driven "Herringbone" large gear The gear 6 is eccentrically connected with the connecting rod 9 through the crank pin shaft 8, and a force sensor 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com