Self-propelled automatic quantitative fertilization device

A quantitative fertilization, self-propelled technology, applied in fertilization devices, planting methods, fertilizer distributors, etc., can solve the problems of poor fertilization uniformity, low work efficiency, and the inability of fertilizers to adjust the amount of fertilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

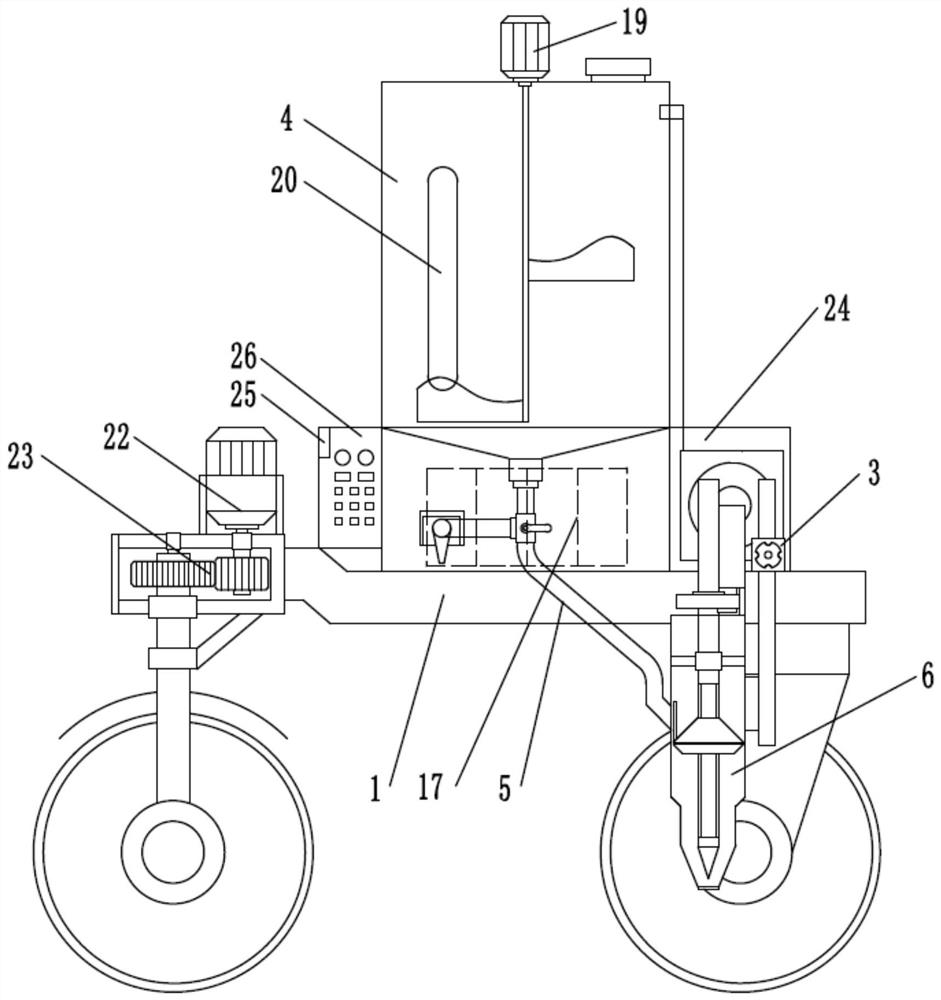

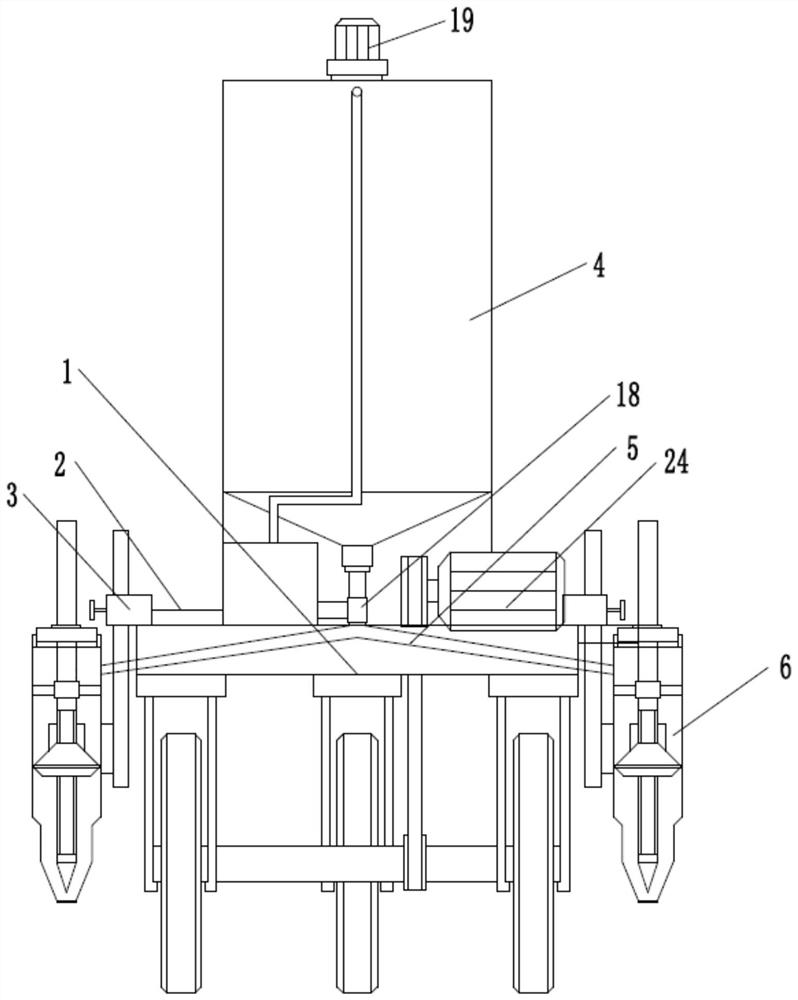

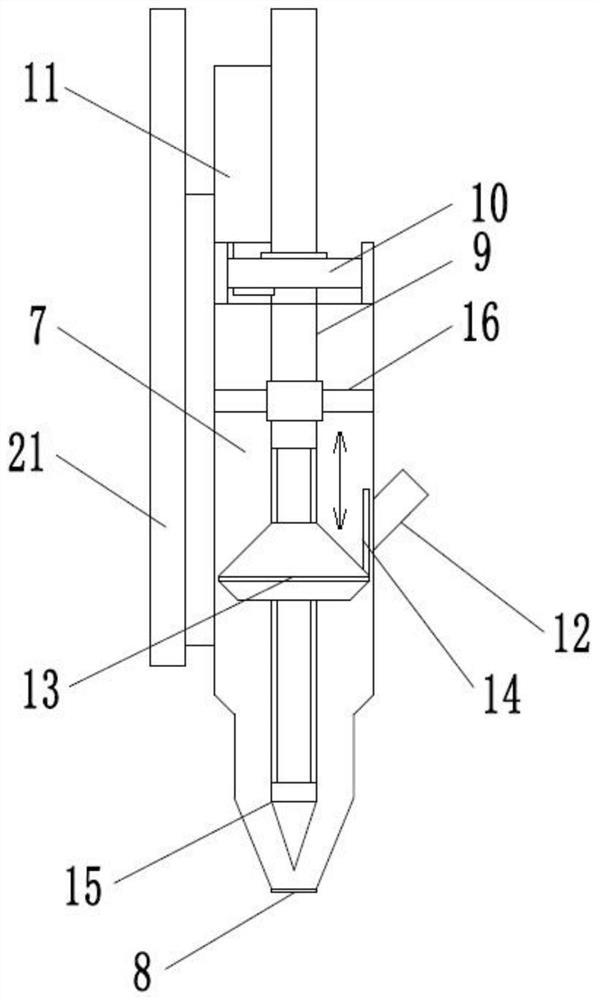

[0016] as attached Figure 1~4 The shown self-propelled automatic quantitative fertilization device comprises a walking vehicle frame 1, and a fertilizer applicator 6 and a material container 4 arranged on the walking vehicle frame 1, and the material container 4 is connected to the fertilizer applicator 6 through a feed pipe 5, and the walking Both sides of the rear part of the vehicle frame 1 are provided with horizontal supports 2 respectively, and fertilization adjustment seats 3 dynamically matched with them are arranged on each horizontal support 2, and the fertilization device 6 is arranged on the fertilization adjustment seats 3; wherein, the fertilization The device 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com