Fluid mixing by means of fluid supply lines with line-specifically associated fluid pumps for liquid chromatography

A fluid supply and liquid chromatography technology, which is applied in liquid variable volume machinery, solid adsorbent liquid separation, pumps, etc., to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

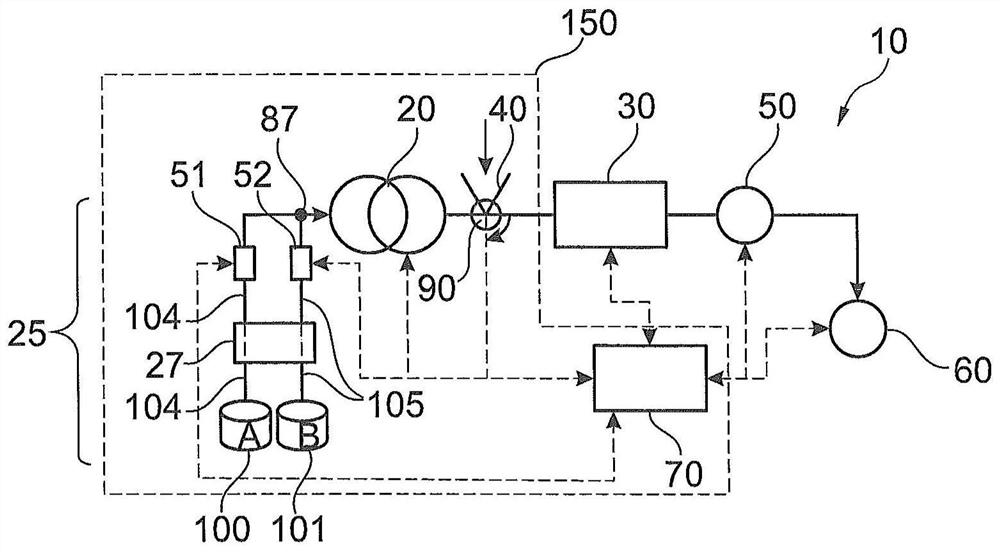

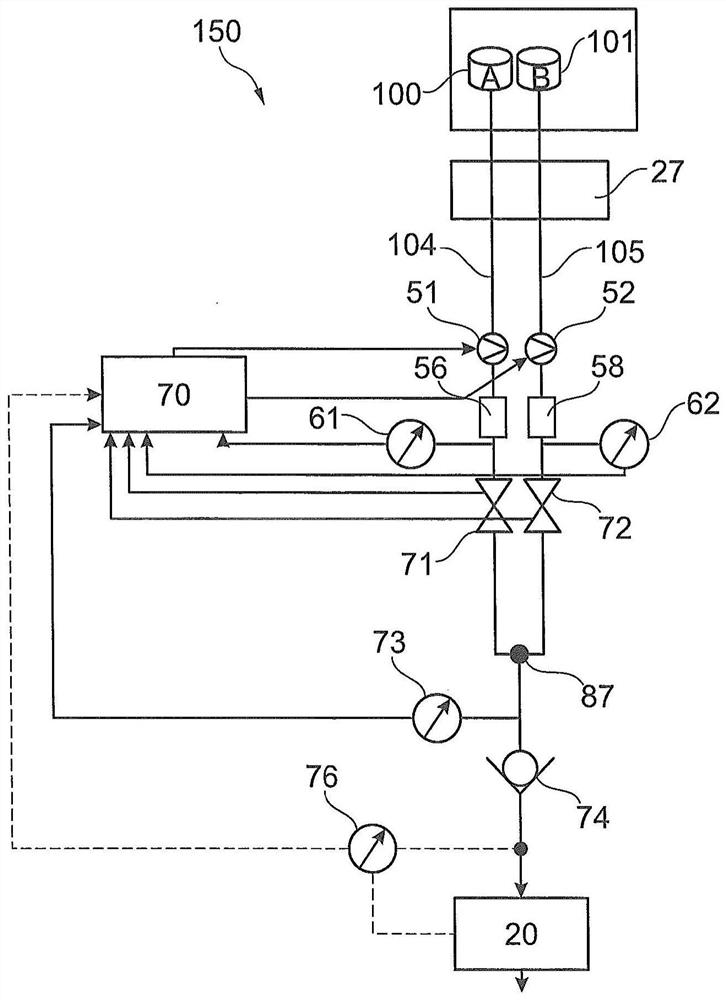

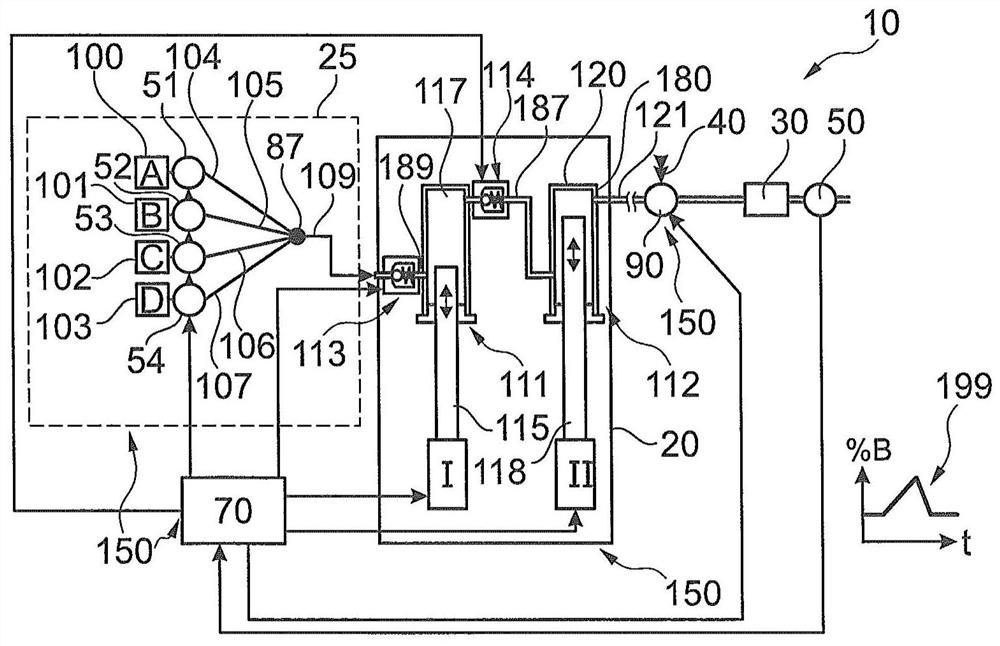

[0046] Before describing exemplary embodiments executed with reference to the accompanying drawings, some basic considerations from which exemplary embodiments of the present invention are derived will be summarized.

[0047] According to an exemplary embodiment of the present invention, in the fluid supply device, each fluid pump is arranged in a respective supply line downstream of each fluid component source. By actively or inactively switching the individual fluid pumps themselves and / or line-specific switching valves operatively coupled thereto, precise fluid composition can be achieved at the merging point of the supply lines, independent of the filling involved in the source of the fluid components. The effect of gravity on level or position height is irrelevant. The provision of such a separate and line- or channel-specific fluid pump avoids the gas phase, since the liquid is supplied under pressure in the suction region upstream of the fluid delivery device, in partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com