Cable interface quick binding device for hydroelectric power generation

A technology of cables and interfaces, which is applied in the field of fast binding devices for cable interfaces used in hydropower generation, and can solve problems such as low binding and fixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

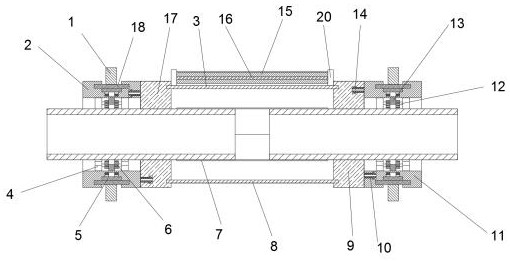

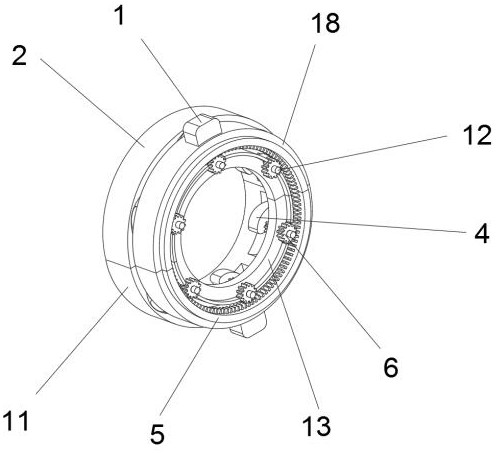

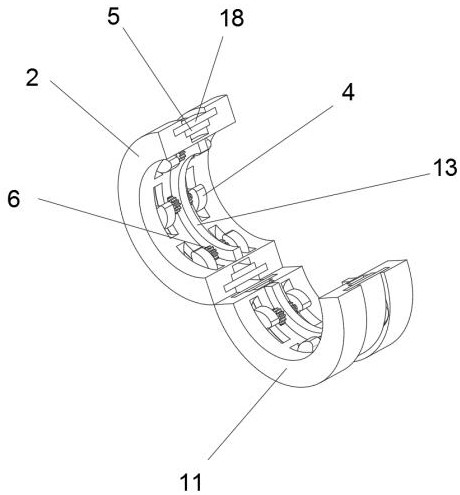

[0027] refer to Figure 1-3 and Figure 5 , a fast binding device for a cable interface for hydroelectric power generation, comprising a clamp ring 2, the bottom of the clamp ring 2 is connected with a clamp ring 11 through a hinge, and the inner walls of the clamp ring 2 and the clamp ring 11 are fixed by bolts. Half ring 13, fixed half ring 13 is fixed with clamping mechanism, and clamp ring one 2 and clamp ring two 11 inwalls all are connected with semicircle slide plate 18 by sliding, and semicircle slide plate 18 fixed rotation mechanism, offers in clamp ring one 2 side walls A card slot 14, a buckle 10 is inserted into the wall of the card slot 14, and the buckle 10 is fixed with a wrapping mechanism.

[0028] Among the present invention, clamping mechanism comprises rotating shaft one 12, and rotating shaft one 12 is connected with fixed semi-ring 13 by bearing, and rotating shaft one 12 outer wall is sleeved with gear 6, and rotating shaft one 12 outer wall both sides...

Embodiment 2

[0035] refer to Figure 4 and Figure 5 , a cable interface fast binding device for hydroelectric power generation. Compared with Embodiment 1, the glue supply mechanism of this embodiment includes the second rotating shaft 16, the second rotating shaft 16 is connected to the support plate 20 through bearings, and the outer wall of the second rotating shaft 16 is sleeved with Tape post15.

[0036] In the present invention, the gluing mechanism includes a chute plate 23, the chute plate 23 and the inner wall of the rotating plate 3 are connected by bolts, the chute plate 23 is inserted with a pressure plate 21, and the pressure plate 21 and the inner wall of the chute plate 23 are connected by bolts. A spring is connected, and the bottom outer wall of the pressing plate 21 is connected with a rotating post 22 by bolts.

[0037]During use, when the rotating plate one 3 rotates, the rotating column 22 rotates accordingly, and the pressing plate 21 presses the tape to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com