Resin sealing device and resin sealing method

A resin sealing device and resin sealing technology are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as insufficient bottom filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

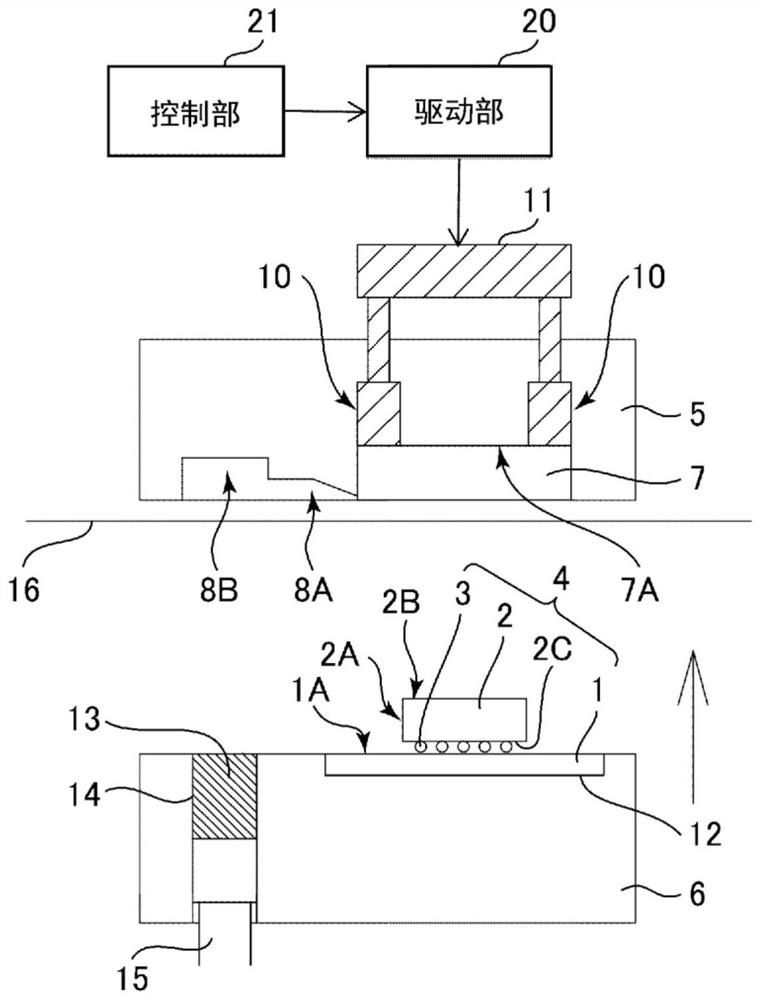

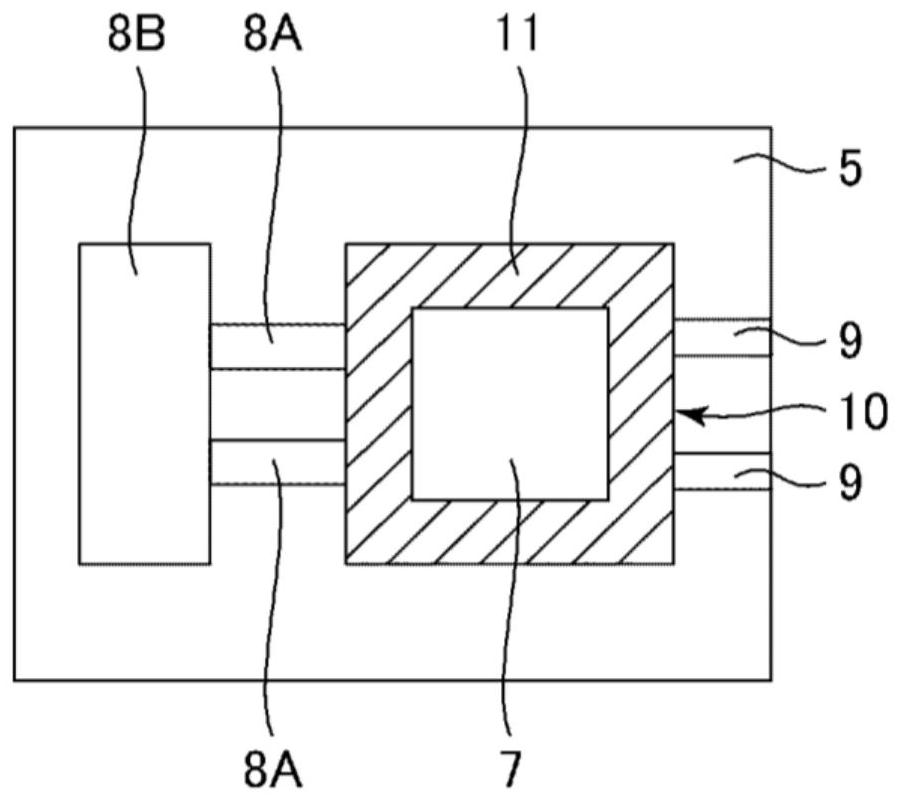

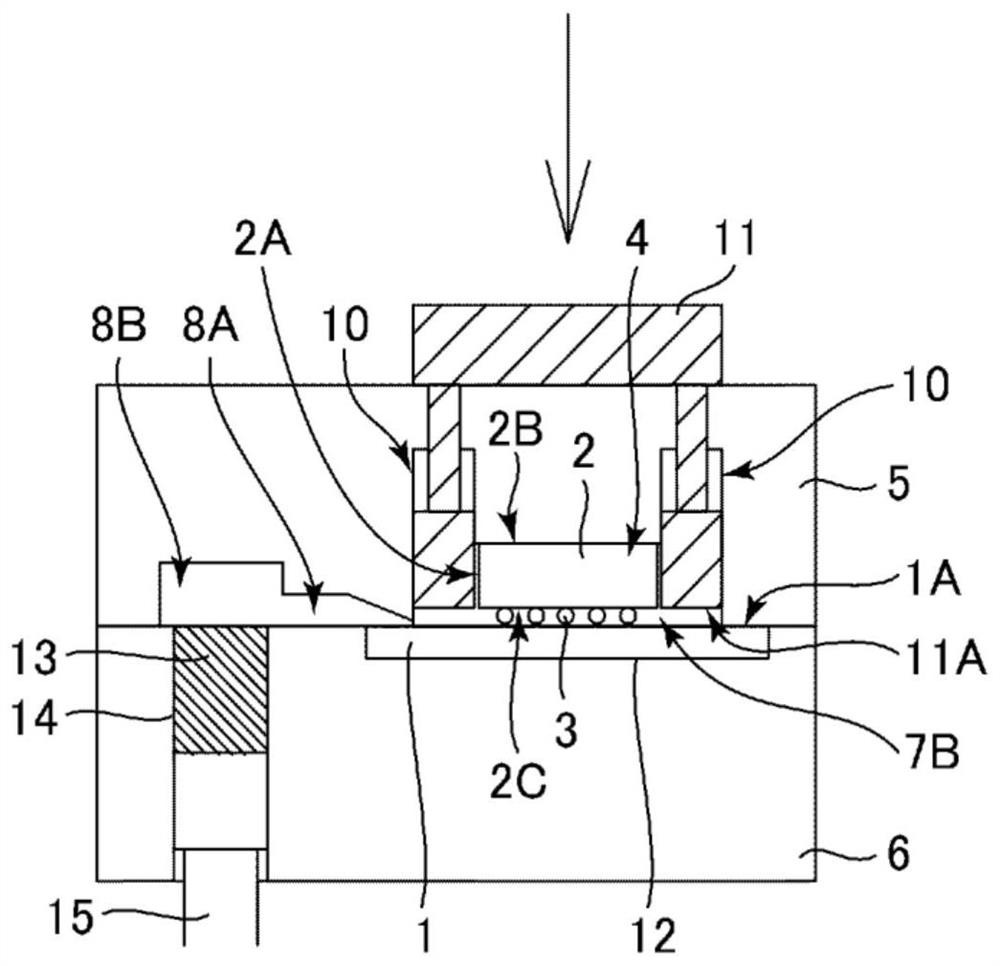

[0032] figure 1 is a schematic front cross-sectional view of a mold of a resin sealing device according to an embodiment of the present invention, figure 2 yes figure 1 Bottom view of the upper mold in, Figure 3 ~ Figure 5 It is a schematic front sectional view showing the resin sealing molding process performed by the resin sealing device of this embodiment.

[0033] Such as figure 1 with figure 2As shown, the resin sealing device according to the embodiment of the present invention is a device for performing resin sealing molding on a molded object 4 formed by flip-chip connecting a semiconductor chip 2 on the surface of a substrate 1 via a connection electrode 3 . The resin sealing device has an upper mold 5 as a first mold and a lower mold 6 as a second mold, and the upper mold 5 and the lower mold 6 can sandwich a molding object 4 .

[0034] Formed on the upper mold 5 are: a cavity recess 7 for accommodating the semiconductor chip 2 mounted on the substrate 1 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com