A double-sided shot blasting derusting machine for building steel plates

A technology for building steel plates and derusting machines, which is applied in metal processing equipment, used abrasive processing devices, manufacturing tools, etc., can solve the problems of reducing shot blasting efficiency, and achieve the effect of improving shot blasting efficiency and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

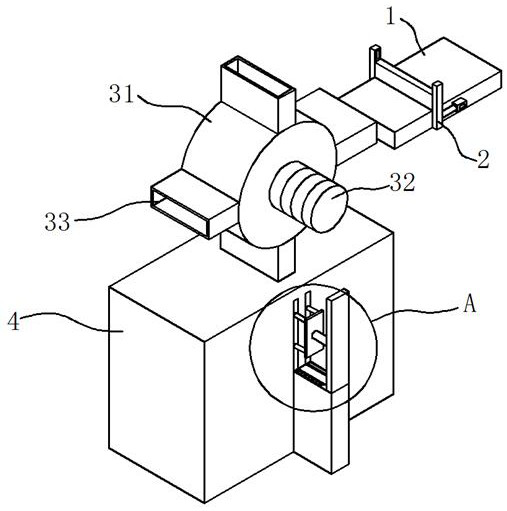

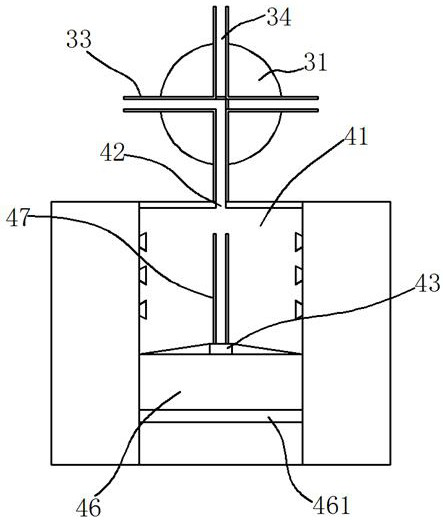

[0027] Refer to attached Figure 1-5 , a double-sided shot blasting derusting machine for building steel plates, comprising a conveyor belt 1, one end of the conveyor belt 1 is provided with a push structure 2, one side of the push structure 2 is provided with a steering structure 3, and the bottom of the steering structure 3 is provided There is a shot blasting machine body 4.

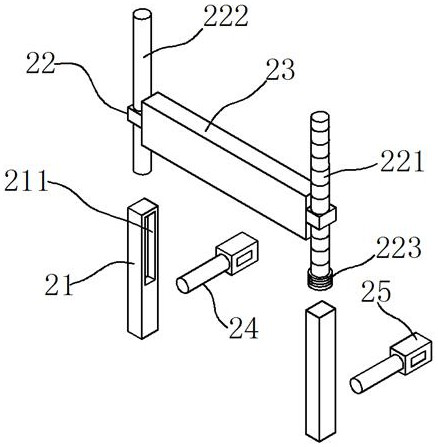

[0028] The pushing structure 2 includes symmetrically arranged support rods 21, the sides of the support rods 21 are provided with first sliding grooves 211, and the first sliding grooves 211 are all matched and connected to the first sliders 22, and the first sliders 22 are respectively arranged on both sides of the push plate 23, and the first slider 22 is respectively matched with the first screw rod 221 and the first slide rod 222, and the bottom of the first screw rod 221 is fixedly connected with the first motor 223; The rod 221, the first sliding rod 222, and the first motor 223 are all arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com