Wall-climbing paint spraying robot

A robot and wall-climbing technology, which is applied in the direction of manipulators, spraying devices, and devices for coating liquid on the surface, etc. It can solve problems such as poor painting effect and uneven painting track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

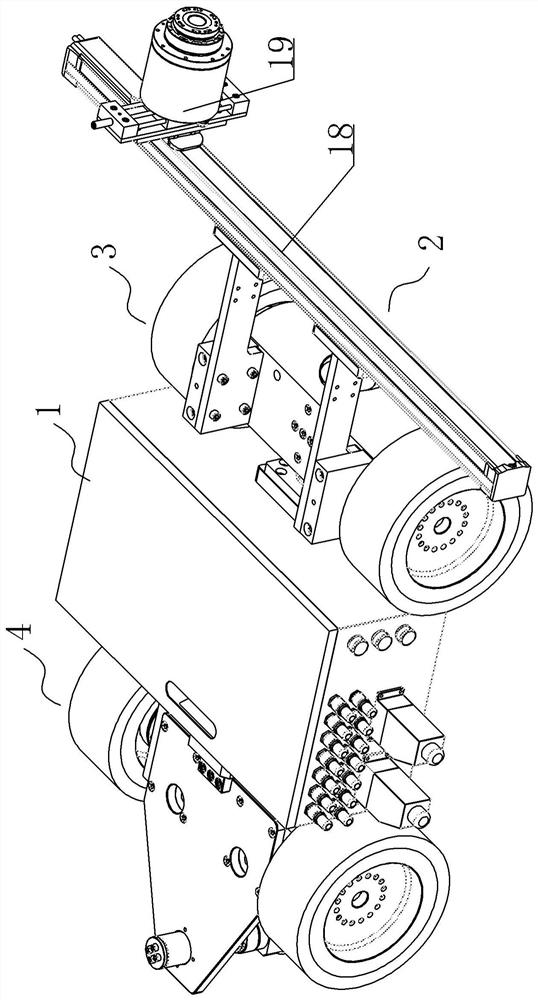

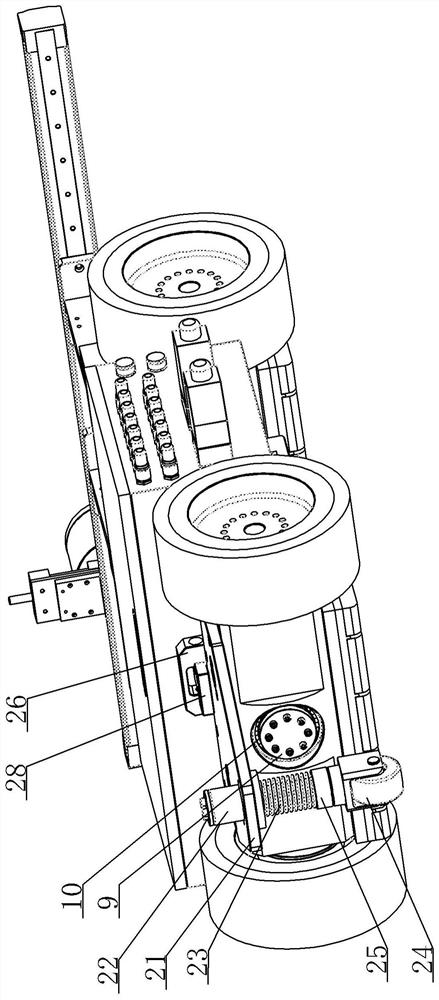

[0018] A wall-climbing painting robot, see Figure 1-Figure 4 : It includes a control module 1, a painting module 2, a fixed axis module 3, a floating axis module 4, and a connection module 5, the control module 1 is installed in the concave support frame 6 of the connection module 5, and the connection module 5 also includes a first The vertical plate 7, the second vertical plate 8, and the exposed end surface of the first vertical plate 7 are fixed with an outwardly protruding rotating shaft 9, the rotating shaft 9 is arranged perpendicular to the first vertical plate 7, and the two ends of the rotating shaft 9 in the length direction are respectively sleeved with bearings 10. The floating shaft module 4 specifically includes a floating shaft frame 11. The floating shaft frame 11 is provided with a through escape hole corresponding to the position of the rotating shaft 9. The floating shaft frame 11 is set on the outer ring of the corresponding side bearing 10. Both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com