Method for reducing residual amount of nitrite in sausages

A nitrite and residue technology, applied in the function of food ingredients, food ingredients as antioxidants, food science and other directions, can solve the effect of improving flavor, can not completely replace the color of nitrite, has no antibacterial and antioxidant role, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

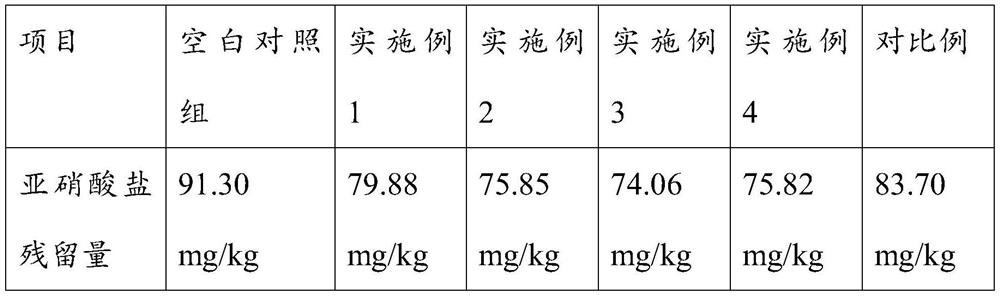

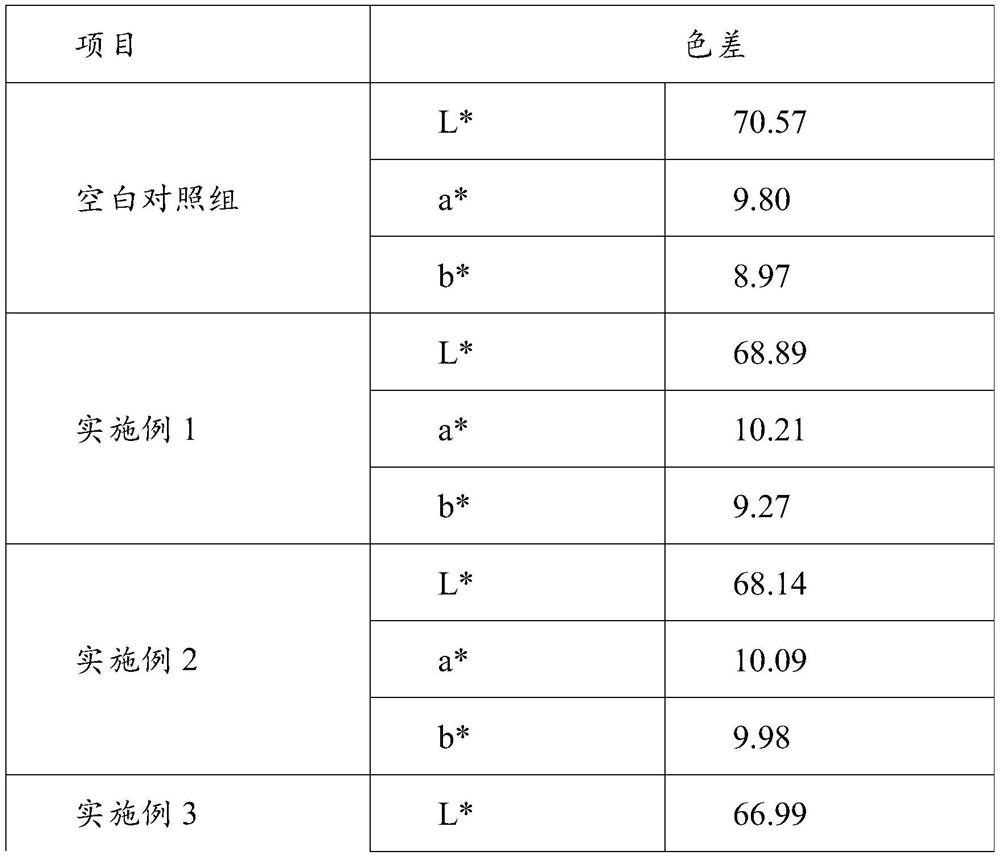

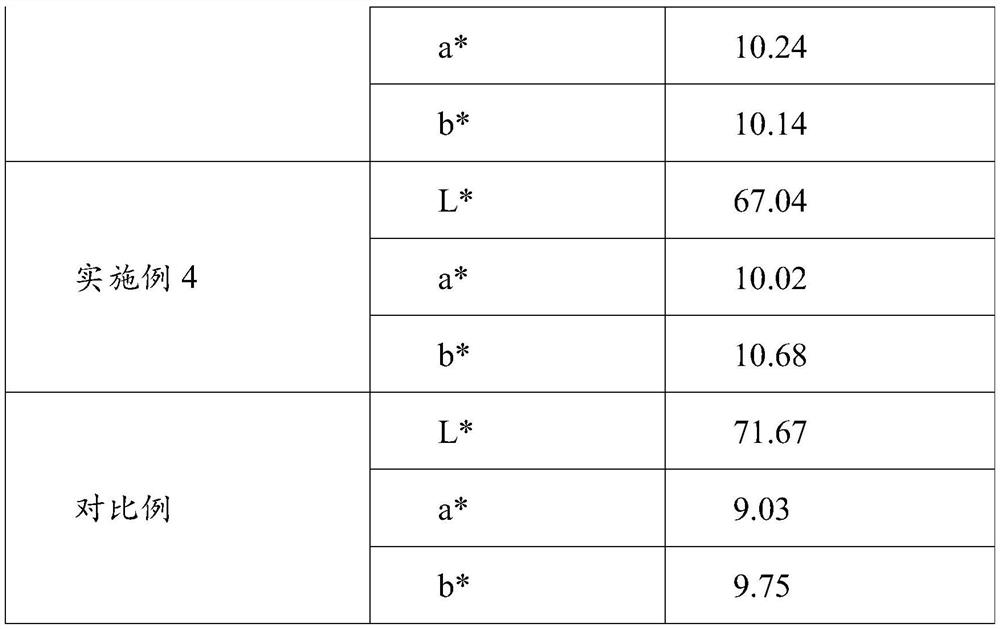

Examples

Embodiment 1

[0017] A method for reducing residual nitrite in sausages, comprising the steps of:

[0018] (1) Remove tendons and blood clots from fresh lean meat, clean them and put them into a meat grinder to grind;

[0019] (2) Clean the pig fat and put it into a meat grinder to grind;

[0020] (3) Evenly mixing the minced fresh lean meat and the minced pig fat to obtain mixed minced meat; wherein, the weight ratio of the fresh lean meat to the pig fat is 85:15.

[0021] (4) Mix the mixed minced meat, edible salt, white pepper powder, sodium nitrite, theaflavin, and ice water evenly, and then marinate at 4°C for 24 hours; wherein, the parts by weight of each raw material are as follows: 100 parts of mixed minced meat, edible 2.5 parts of salt, 0.3 parts of white pepper powder, 0.015 parts of sodium nitrite, 0.01 parts of theaflavin, and 10.02 parts of ice water.

[0022] (5) Fill the marinated minced meat into the casing, and buckle at both ends;

[0023] (6) Boil the stuffed sausage ...

Embodiment 2

[0025] A method for reducing residual nitrite in sausages, comprising the steps of:

[0026] (1) Remove tendons and blood clots from fresh lean meat, clean them and put them into a meat grinder to grind;

[0027] (2) Clean the pig fat and put it into a meat grinder to grind;

[0028] (3) Evenly mixing the minced fresh lean meat and the minced pig fat to obtain mixed minced meat; wherein, the weight ratio of the fresh lean meat to the pig fat is 85:15.

[0029] (4) Mix the mixed minced meat, edible salt, white pepper powder, sodium nitrite, theaflavin, and ice water evenly, and then marinate at 4°C for 24 hours; wherein, the parts by weight of each raw material are as follows: 100 parts of mixed minced meat, edible 2.5 parts of salt, 0.3 parts of white pepper powder, 0.015 parts of sodium nitrite, 0.02 parts of theaflavin, and 10.01 parts of ice water.

[0030] (5) Fill the marinated minced meat into the casing, and buckle at both ends;

[0031] (6) Boil the stuffed sausage ...

Embodiment 3

[0033] A method for reducing residual nitrite in sausages, comprising the steps of:

[0034] (1) Remove tendons and blood clots from fresh lean meat, clean them and put them into a meat grinder to grind;

[0035] (2) Clean the pig fat and put it into a meat grinder to grind;

[0036] (3) Evenly mixing the minced fresh lean meat and the minced pig fat to obtain mixed minced meat; wherein, the weight ratio of the fresh lean meat to the pig fat is 85:15.

[0037] (4) Mix the mixed minced meat, edible salt, white pepper powder, sodium nitrite, theaflavin, and ice water evenly, and then marinate at 4°C for 24 hours; wherein, the parts by weight of each raw material are as follows: 100 parts of mixed minced meat, edible 2.5 parts of salt, 0.3 parts of white pepper powder, 0.015 parts of sodium nitrite, 0.03 parts of theaflavin, and 10 parts of ice water.

[0038] (5) Fill the marinated minced meat into the casing, and buckle at both ends;

[0039] (6) Boil the stuffed sausage in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com