Multi-layer rotor magnetic steel structure of permanent magnet motor for high-power-density new energy automobile

A new energy vehicle, high power density technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts and other directions, can solve the weak magnetic speed regulation range and torque density can not meet the high power density automotive permanent magnets Motor performance requirements and other issues, to avoid irreversible demagnetization, improve utilization, increase field weakening ability and reluctance torque component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

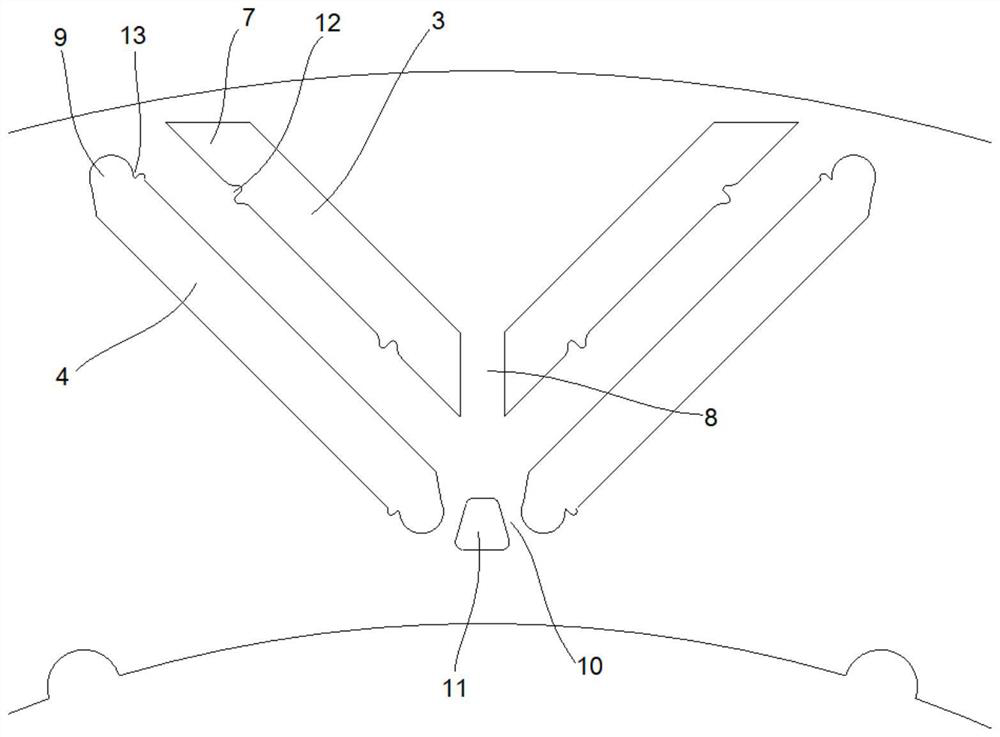

[0024] as attached Figures 1 to 4 The multi-layer rotor magnetic steel structure of the permanent magnet motor for new energy vehicles with high power density includes a rotor core 1, the section of the rotor core 1 is circular, and the upper edge of the rotor core 1 is Several magnetic steel groove sets 2 are arranged at intervals, and the several magnetic steel groove sets 2 are arranged at equal angles.

[0025] The magnetic steel groove group 2 has a double V-shaped structure, and a single magnetic steel groove group 2 is composed of a first layer of V-shaped magnetic steel grooves 3 and a second layer of V-shaped magnetic steel grooves 4 . The first layer of magnetic steel 5 and the second layer of magnetic steel 6 are respectively placed in the first layer of V-shaped magnetic steel grooves 3 and the second layer of V-shaped magnetic steel grooves 4 .

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com