Self-adaptive fuzzy neural network control method for pneumatic position servo system

A neural network control, fuzzy neural network technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem that the tracking control accuracy of the pneumatic position servo system is difficult to meet the requirements, and reduce the impact of system performance. , the effect of high tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

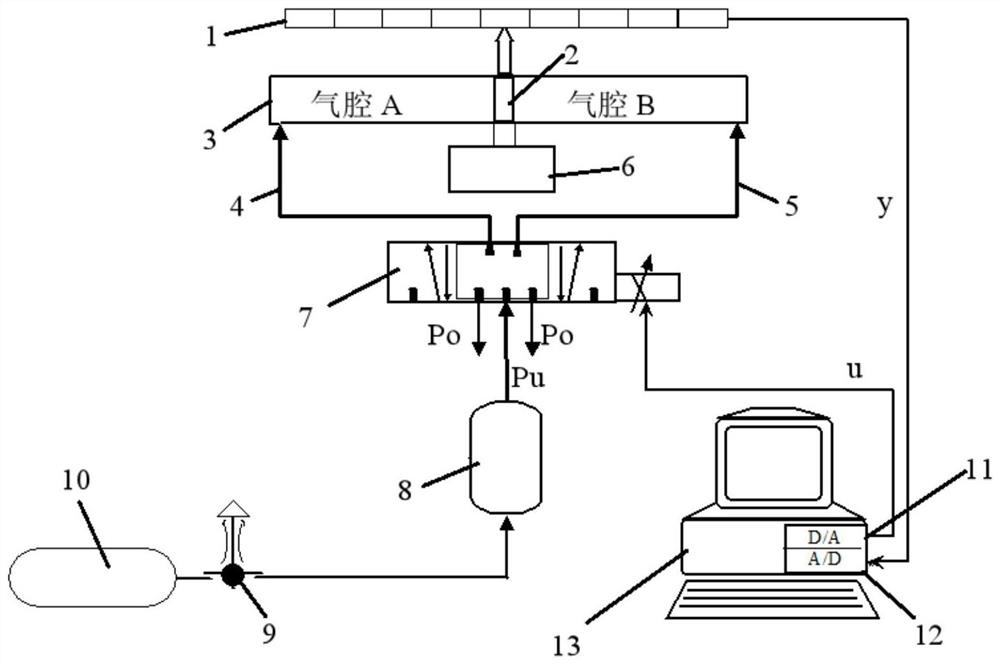

[0092] In this embodiment, the product models selected for the main components in the pneumatic position servo system are:

[0093] Cylinder 3 adopts the model DGPL-25-450-PPV of FESTO Company;

[0094] The model used by the proportional valve 7 is MPYE-5-1 / 8-HF-010-B;

[0095] The model adopted by position detection element 1 is MLO-POT-450-5TLF displacement detector;

[0096] The model used by the universal data acquisition card is PCI2306, which contains figure 1 Middle A / D conversion module 12 and D / A conversion module 11;

[0097] The model that computer 13 adopts is that CPU is P2 1.2GHz, and the control software built-in in computer adopts VB to compile, shows the variation curve of relevant variable in the control process by screen display.

[0098] The control objectives of this embodiment are respectively set as

[0099] Reference signal 1: The sinusoidal signal is

[0100] the y m =A 1 sin ω 1 t (19)

[0101] Among them, A 1 = 111.65, ω 1 =0.5π.

[0102]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com