Method for evaluating CT size measurement precision by using DVC deformation algorithm

A technology of measurement accuracy and deformation algorithm, which is applied in the direction of measurement devices, calculations, 3D modeling, etc., can solve the problems that it is difficult to accurately evaluate the error error, and the CT measurement error cannot be completely traced to the source, so as to achieve a large amount of data, comprehensive and reliable error The effect of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In Example 1, taking the CT size measurement accuracy evaluation of metal foam aluminum as an example, the specific implementation process is as follows:

[0026] Step 1. According to the sample to be tested for CT size measurement, prepare a standard sample for size measurement accuracy evaluation. The standard sample used here is the sample to be tested itself, which is a cubic foam with an external dimension of 1.3cm×1.3cm×1.3cm Aluminum samples;

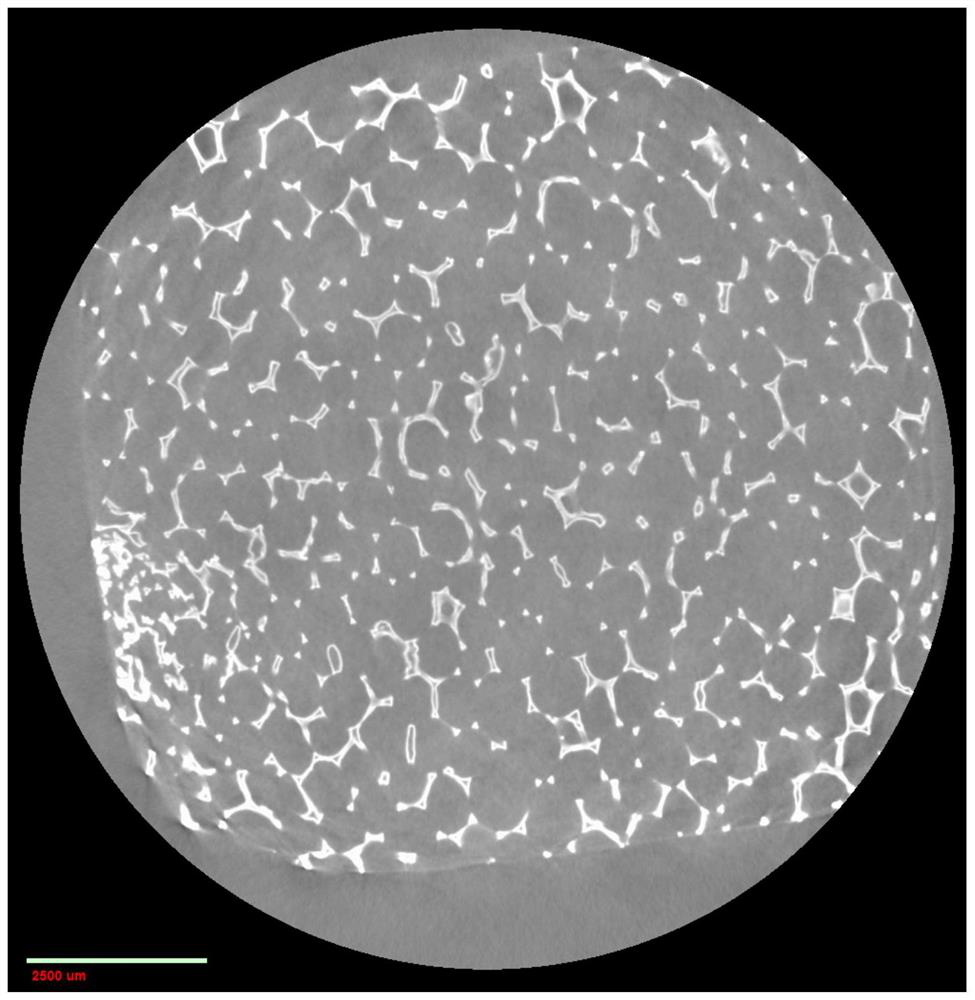

[0027] Step 2. Under a certain CT test condition, the CT equipment is used to scan the sample twice consecutively to obtain two sets of three-dimensional CT image data under the same test condition. The imaging equipment used here is a Zeiss Xradia510 X-ray microscope, and the scanning parameters are : The X-ray accelerating voltage is 140kV, the power is 10w, and the resolution is 13 microns. The typical CT data slice obtained is as follows figure 1 shown;

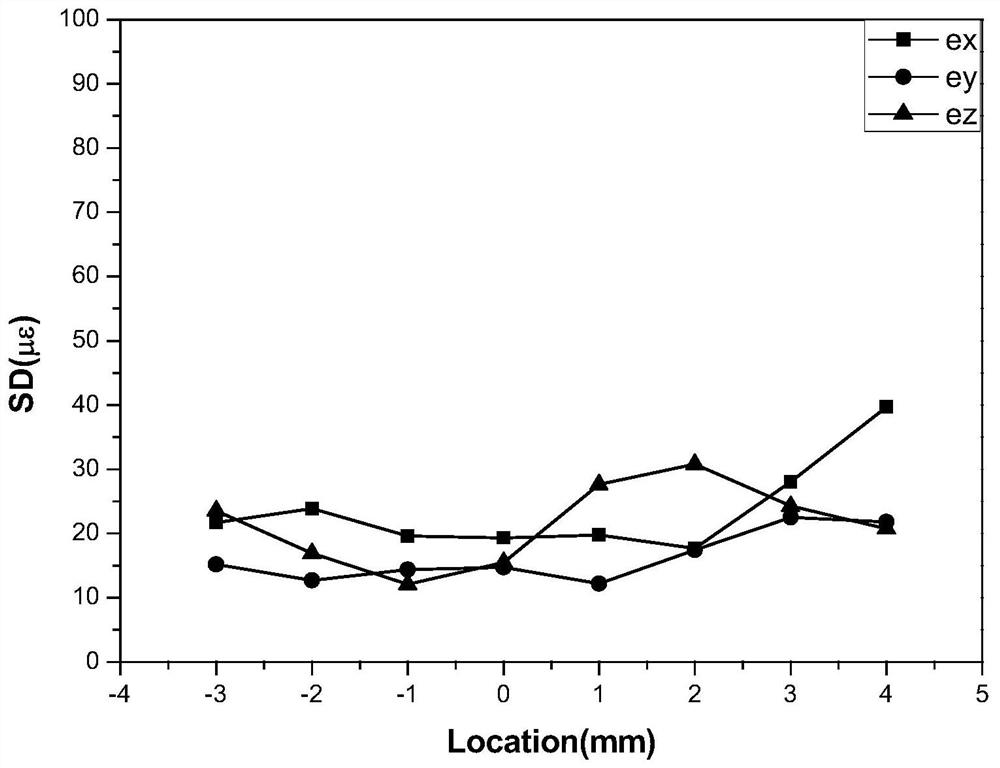

[0028] Step 3: Use the DVC algorithm to perform DVC calculatio...

Embodiment 2

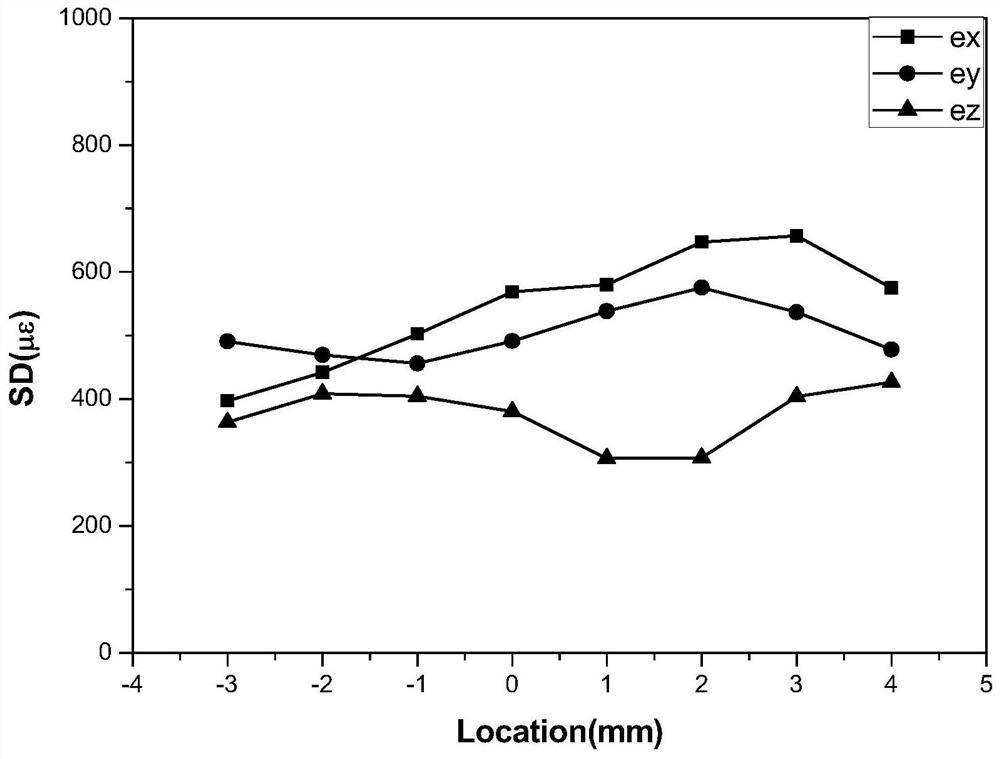

[0033] Compared with the CT test of embodiment 1, embodiment 2 only changes the voltage and power of CT test conditions, changes 140kV, power 10w to 40kV, 3w, other is the same as embodiment 1; The strain values in the 8 strain windows were statistically analyzed, and a series of standard deviations of the obtained strains along the vertical direction were listed in image 3 .

Embodiment 3

[0035] Compared with embodiments 1 and 2, embodiment 3 changes the voltage and power of the CT test conditions, changes the test voltage and power to 80kV and 7w respectively, and compares the difference between inserting a filter and not inserting a filter, and finally layer by layer Statistical analysis is performed on the strain values in 8×8 strain windows in the horizontal direction, and a series of standard deviations of the obtained strains along the vertical direction are listed in Figure 4~5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com