Control structure and method for preventing welding deformation of upwarp type top beam

A welding deformation and structure control technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the effect of the upturned top beam is not obvious, and achieve the effect of solving welding deformation and controlling welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The preferred specific implementation method of the upturned top beam prevention welding deformation control structure of the present invention is:

[0024] The top beam includes a top plate, the front end of the top plate is welded with a tongue plate, including clips for assembly, before welding, the top plate and the tongue plate are clamped with the clips, and the tongue plate is equipped with a welding mechanism for welding with the top plate. Anti-deformation structures with opposite deformation directions and similar magnitudes.

[0025] Before welding, two strip-shaped fixing plates are longitudinally fixed on the back of the top plate, and pad iron is added between the top plate and the fixing plate, and the thickness of the pad iron is the deformation amount of the top plate after welding.

[0026] The method for controlling welding deformation of the above-mentioned upturned top beam preventing welding deformation control structure includes:

[0027] Accordi...

specific Embodiment

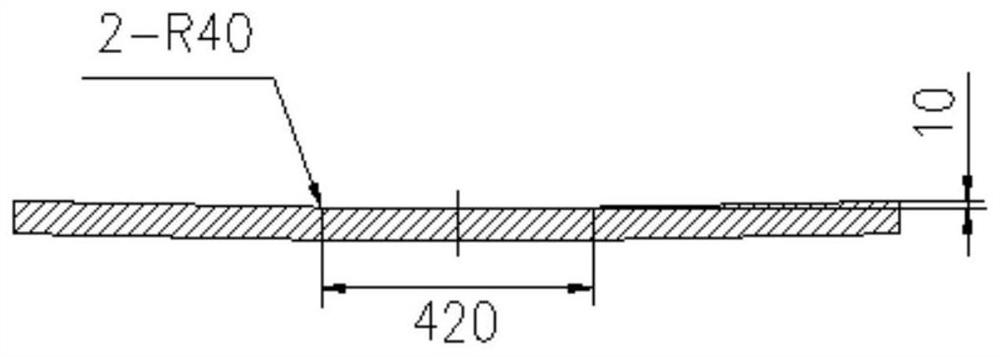

[0031] The anti-deformation method of the tongue plate is shown in Figure 1. According to the structural characteristics of the top beam parts and the analysis of the deformation after welding, a deformation of the tongue plate is opposite to the welding deformation direction and similar in size in advance, and the clips are used when the top beam parts are assembled once. The fixed tongue plate is used to offset the deformation of the structural parts after welding and prevent bending deformation and angular deformation.

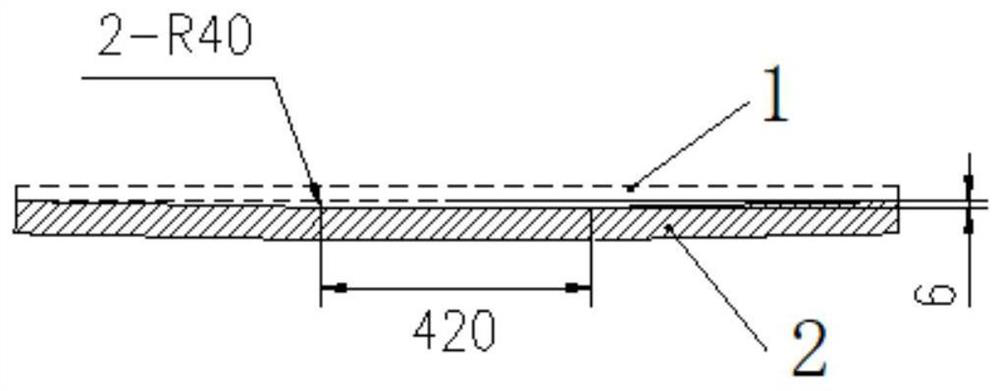

[0032] The roof fixture fixing method is shown in Figure 2. For a structure with a thin roof beam and a large upwarp, two long strips are fixed at an appropriate position behind the roof. Add iron pads between the fixed plates to pre-deform the top plate, and weld temporary spot welds around the fixed plates to reduce the wave deformation after welding. This welding fixture can also be used to increase the rigidity and restraint of the structure.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com