Flexible joint for railway vehicle braking system

A braking system, flexible joint technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, branch pipeline, etc., can solve the problems of easy leakage, flange fastener pipeline leakage, etc., to achieve extended use The effect of longevity, reduction of verticality, cost saving of train inspection and factory repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

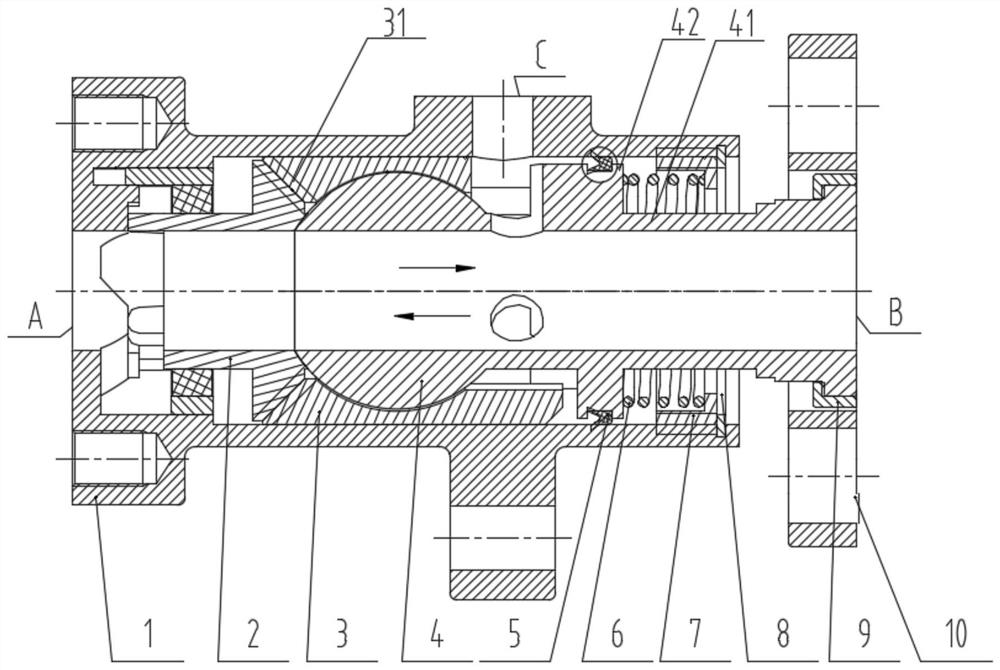

[0043] The embodiment is basically as Figure 1 to Figure 4 As shown: this embodiment provides a flexible joint for a railway vehicle braking system, including a flexible three-way body 1, a torsion bar assembly 2, a swivel joint body 4 and a flange body 10. Specifically, the left end of the flexible three-way body 1 has a second A connection surface A, the flexible three-way body 1 is connected to the brake main pipe on its left side through the first connection surface A; and the top side wall of the flexible three-way body 1 has a third connection surface C, and the flexible three-way body 1 passes through the third connection surface C It is connected with the branch gas path to form a flexible joint tee structure.

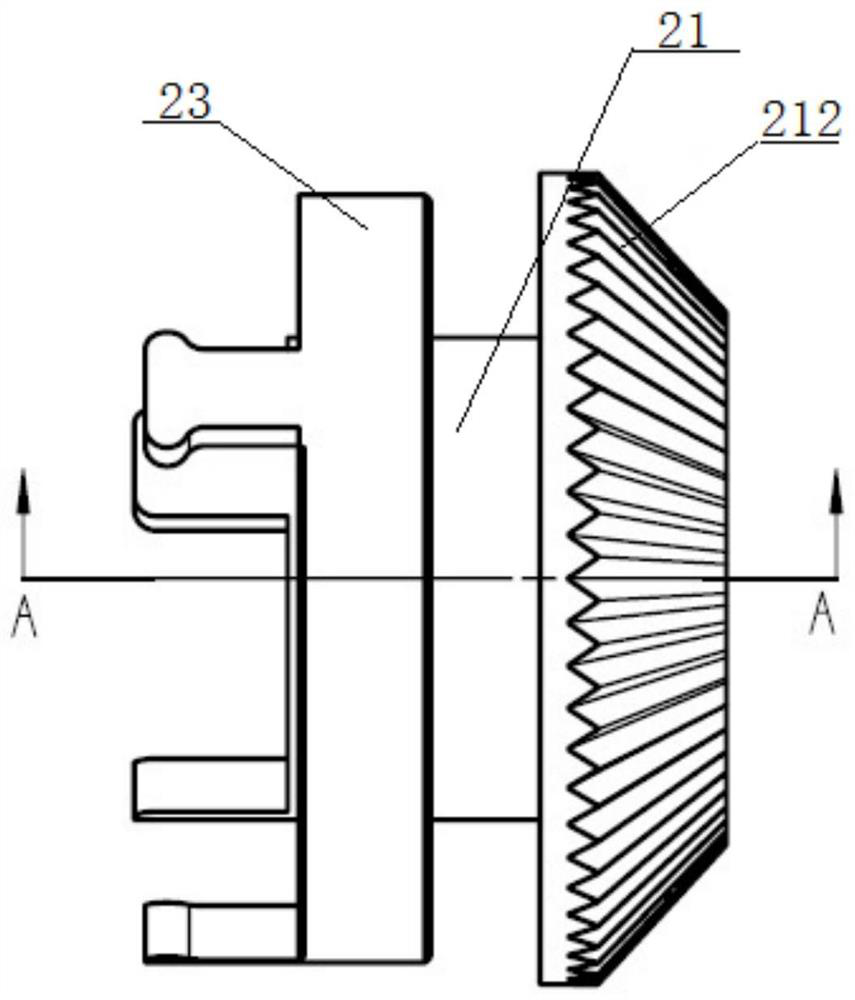

[0044] Such as figure 2 As shown, the torsion bar composition 2 provided in this embodiment is arranged in the flexible tee body 1 and close to the side of the first connecting surface A, and the torsion bar composition 2 is connected with the inner side wal...

Embodiment 2

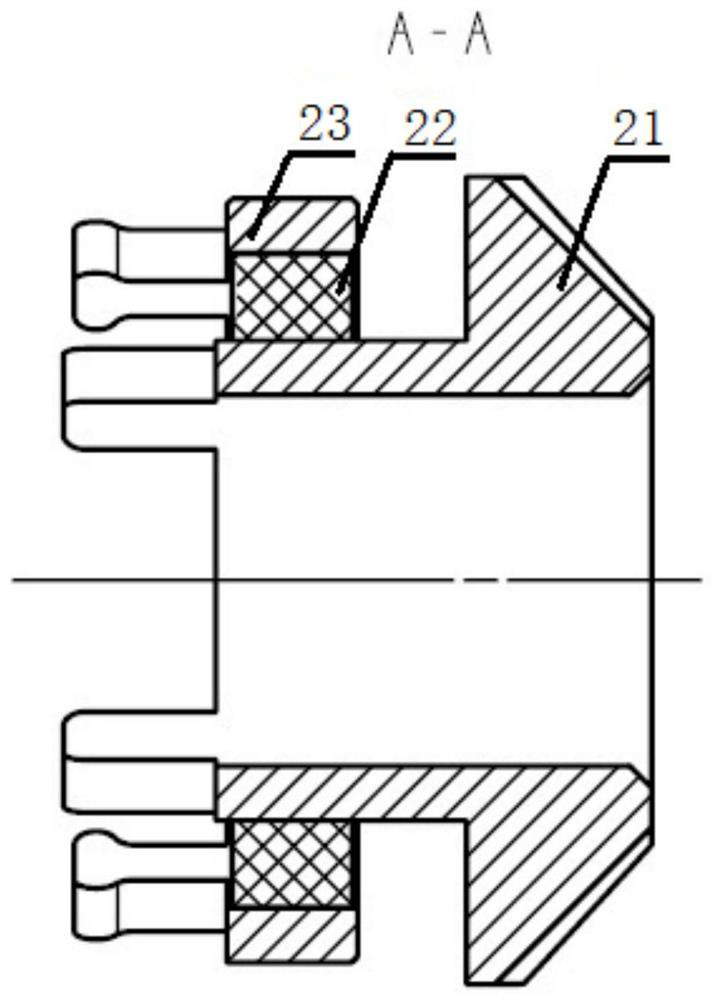

[0050] As a preferred embodiment of Embodiment 1, Embodiment 2 is basically the same as Embodiment 1, except that: please combine figure 2 with image 3 As shown, this embodiment provides a flexible joint for a railway vehicle braking system. Aiming at solving the technical problem that it is difficult to replace the sealing ring in vehicle train inspection, the torsion bar composition 2 provided by this embodiment includes a torsion bar 21, a torsion spring 22 and a The limiting outer ring 23 and the torsion spring 22 are arranged between the torsion bar 21 and the limiting outer ring 23, so that the torsion bar 21 and the limiting outer ring 23 can rotate relative to each other, so that the torsion bar 21 has a degree of freedom of rotation, It can also be reset under the action of the spring 6. Combined with the design of the rotary joint body 4, it can effectively meet the misalignment of the connection center of the adjacent brake pipe system, without affecting the seali...

Embodiment 3

[0056] As a preferred embodiment of Embodiment 2, Embodiment 3 is basically the same as Embodiment 2. The difference is that this embodiment provides a flexible joint for a railway vehicle braking system. In order to realize the flexible joint is easy to install and easy to manufacture, A spring holder 7 is provided on the inner side of the end of the flexible tee body 1 close to the spring 6. The spring holder 7 is fixedly connected with the inner wall of the flexible tee body 1, and the extension section 41 of the rotary joint body 4 has a direction perpendicular to the centerline of the brake pipe air circuit. The raised portion 42 of the spring 6 abuts against the raised portion 42 and the right end of the spring 6 against the spring holder 7 . With the above-mentioned structure, the spring holder 7 designed according to the spring 6 can effectively ensure its installation stability, and the design of the spring holder 7 can make the right end of the flexible tee body 1 hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com