Assembling method of fabricating type partition keel profile through clamping plate buckling part

An assembly method and assembly technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of incompleteness, inconvenience and unreasonable use, etc., and achieve the effect of simple structure, improved assembly efficiency, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

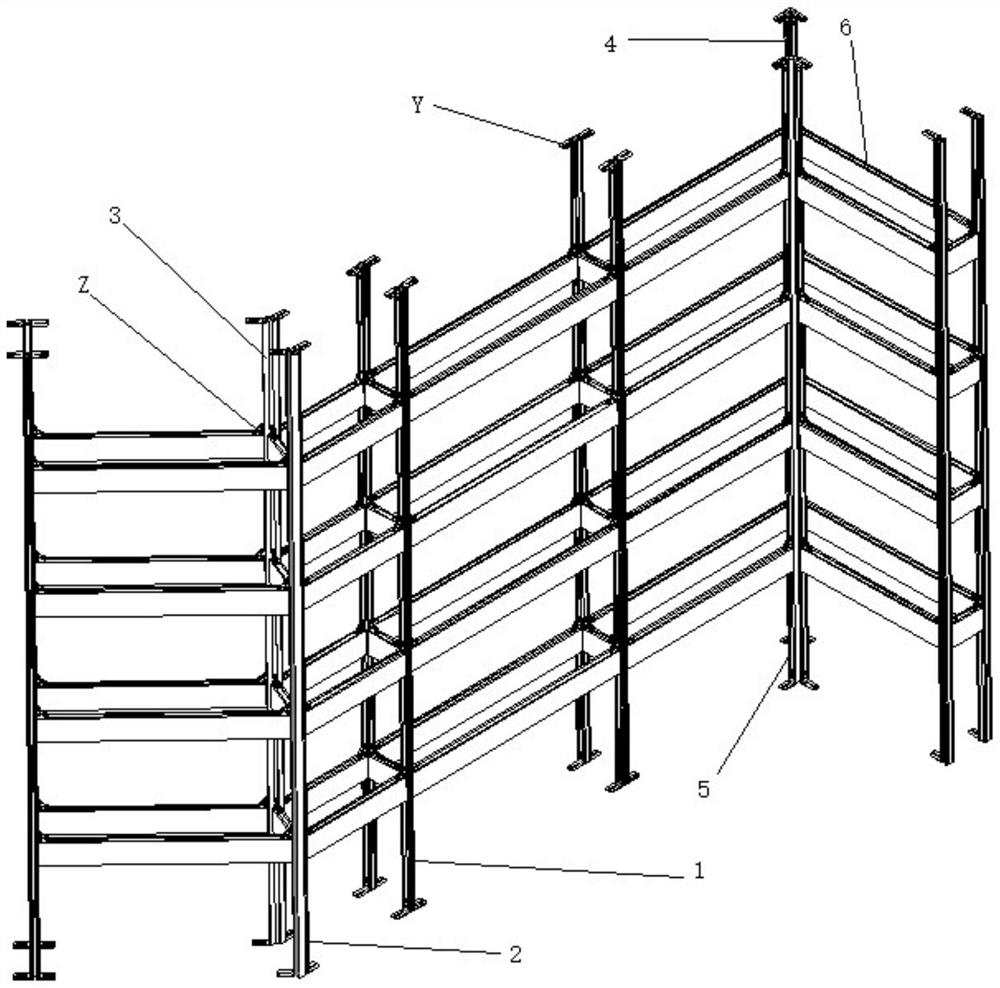

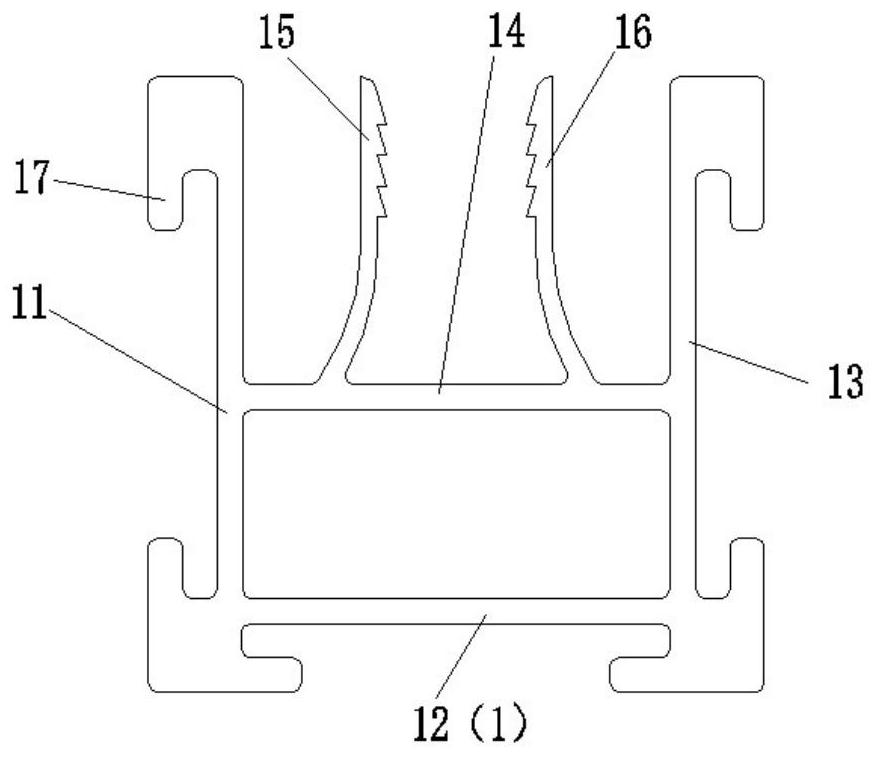

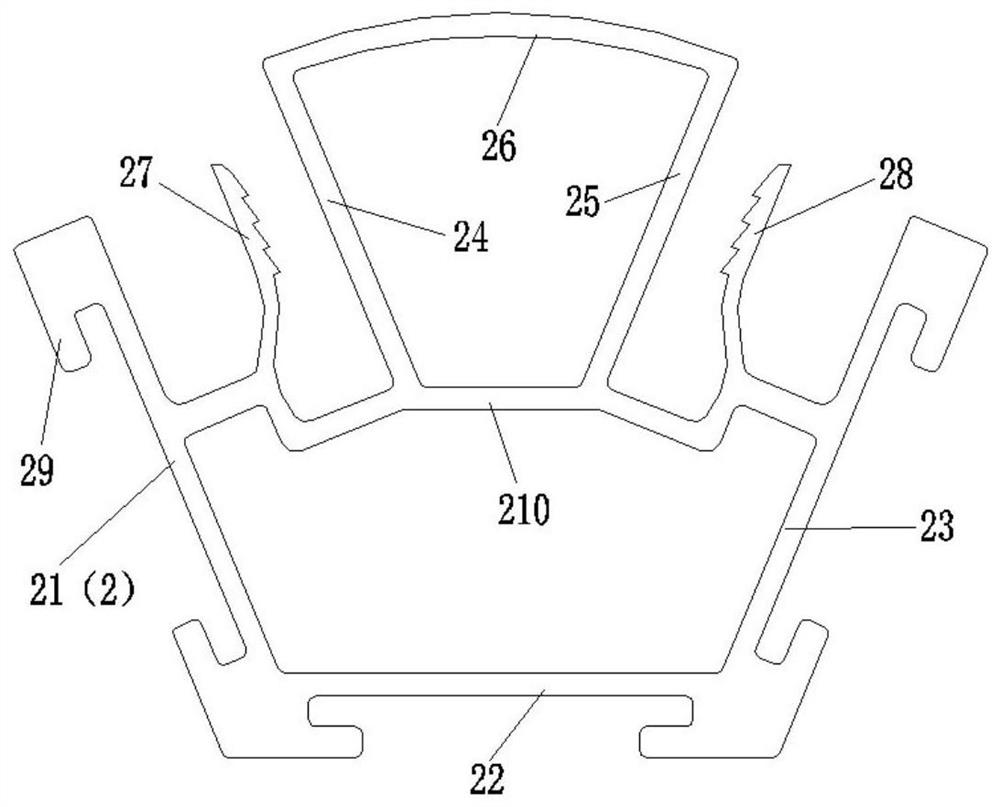

[0077] An assembly method of an assembled partition wall keel profile using clip fasteners according to the present invention adopts an assembled partition wall keel profile through the clip clips and wall panels contained in it to assemble; the assembled partition wall keel The profile includes a vertical column 1 for two wall panels 01 whose panels are connected in a straight line, an obtuse angle male column 2 for connecting the panels of two wall panels 01 at an obtuse angle, and an obtuse angle for the panels of two wall panels 01 Any one of the obtuse-angle female angle column 3 for connection, the right-angle male angle column 4 used for connecting the board surfaces of two wall panels 01 at right angles, and the right-angle female angle column 5 use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com