A kind of preparation method of the uv resin of surface rapid solidification

A fast-curing, resin-based technology, applied in the field of patented UV curing, can solve problems such as strong odor and unstable storage, and achieve the effects of low odor, reduced dosage, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

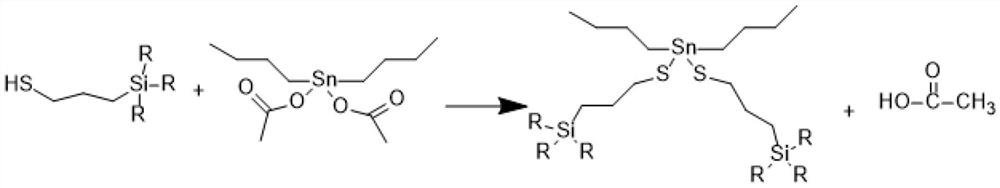

Method used

Image

Examples

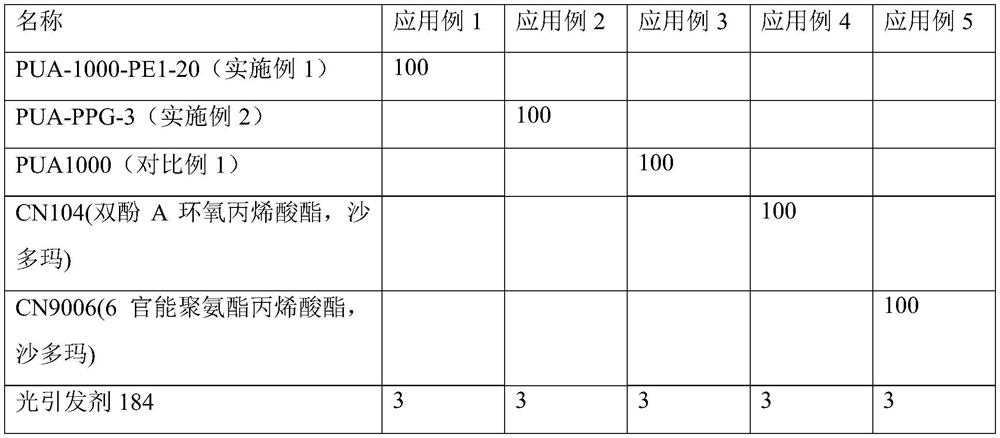

Embodiment 1

[0042] A kind of preparation method of the UV resin of surface fast solidification, concrete steps are as follows:

[0043] S1-1: Add 236.98 (2mol) of hydroxyethyl acrylate (HEA, purity 98%) and 444.48g (2mol) of diisocyanate IPDI into the reactor, stir well, add 0.32g of dibutyltin diacetylacetonate, 0.32 gCC-01 catalyst, 0.4g p-hydroxybenzoic acid, 0.1g 3,5-di-tert-butyl-4-hydroxybenzoic acid, 0.5g p-hydroxyanisole, use a low-temperature thermostat to control the internal temperature at 10-15°C for 3h Obtain a semi-capped prepolymer;

[0044] S1-2: Then add 800g (0.8mol) of macromolecular polyol PTMG1000 (f=2, Mn=1000, polytetrahydrofuran ether glycol, and maintain 70-80°C for 3h;

[0045] S1-3: Then add 108.96g (0.2mol) of multi-functional mercaptan Karenz MT PE1 and maintain the reaction at 80-85°C for 4h to obtain the UV resin, numbered PUA-1000-PE1-20, and its NCO residue was detected Less than 0.1%.

Embodiment 2

[0047] A kind of preparation method of the UV resin of surface fast solidification, concrete steps are as follows:

[0048] S2-1: Add 450g (1mol) of macromolecular polyol Dow CP450 (f=3, Mn=450, polypropylene glycol) and 522.48g (3mol) of diisocyanate TDI into the reactor, stir well and add 0.22g Dibutyltin diacetylacetonate, 0.4g CC-01 catalyst, 0.4g p-hydroxybenzoic acid, 0.3g 3,5-di-tert-butyl-4-hydroxybenzoic acid, 0.8g p-hydroxyanisole, controlled by low temperature thermostat React at an internal temperature of 15-20°C for 3.5 hours;

[0049] S2-2: Add 227.58g (2mol) of hydroxyethyl acrylate (HEA, purity 98%), and keep the reaction at 70-75°C for 2.5h;

[0050] S2-3: Add 199.28g (0.5mol) of trimethylolpropane tris(3-mercaptopropionate), and maintain the reaction at 75-80°C for 2h;

[0051] S2-4: Add 155.48g HDDA, stir evenly, and discharge to obtain PUA-PPG-3, whose NCO residue is less than 0.1% after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com