Equipment for preparing chemical fertilizer from wet garbage

A garbage and fertilizer technology, applied in the field of wet garbage fertilizer equipment, can solve the problems of inflow into the soil layer, environmental pollution, etc., and achieve the effect of solid-liquid separation and convenient sewage separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

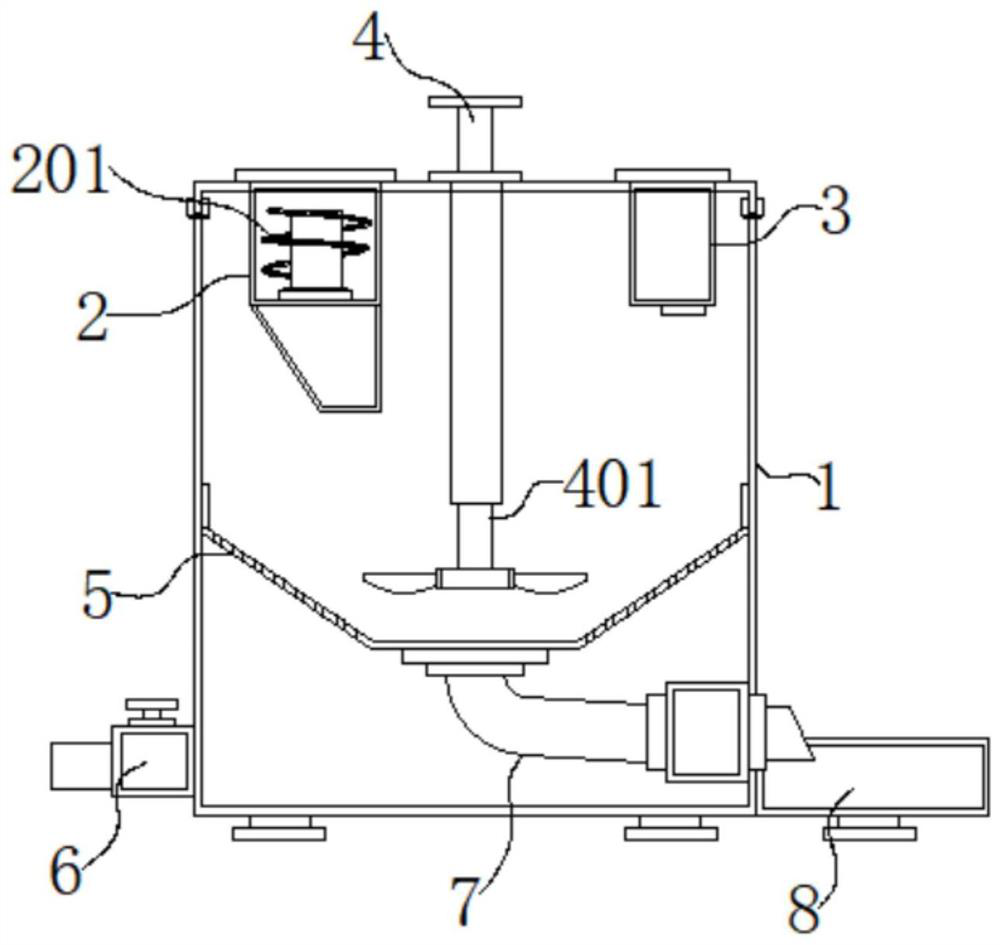

[0020] see Figure 1-4 middle,

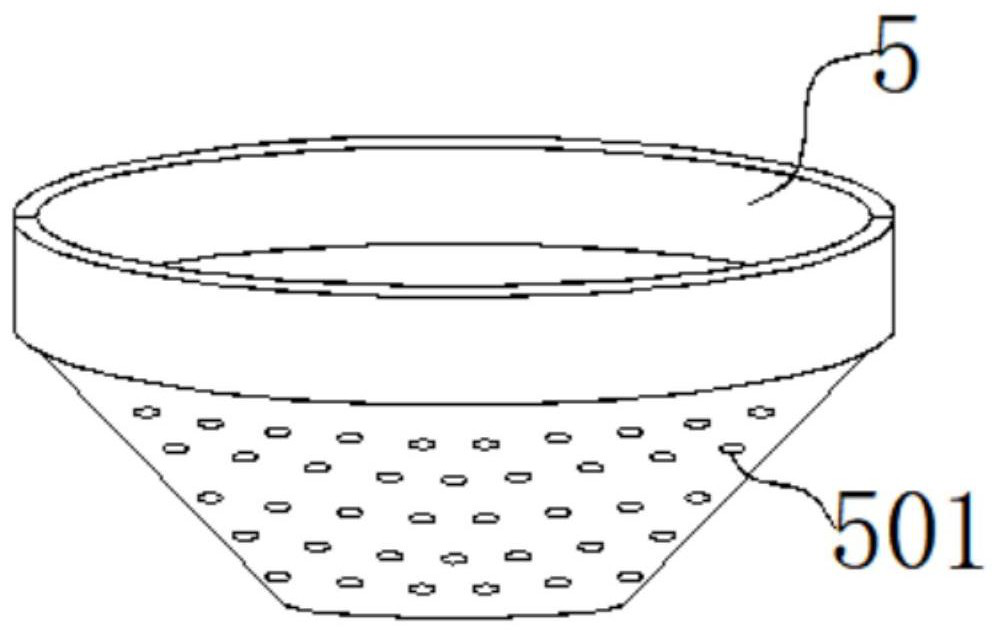

[0021] The equipment for making fertilizer from wet garbage provided in this embodiment includes a tank body 1, a pouring inlet 2 is arranged on the left side of the top of the tank body 1, a screw crusher 201 is arranged in the pouring inlet 2, and a sprinkler is arranged on the right side of the top of the tank body 1. A feeder 3, a mixer 4 is arranged on the top middle side of the tank body 1, a stirring blade 401 is arranged below the mixer 4, a funnel 5 is arranged on the inner side of the tank body 1, and a plurality of water leakage holes 501 equidistantly arranged are arranged on the bottom of the funnel 5, A plurality of heating rods 502 are arranged at the inner bottom of the funnel 5, and an opening 503 is arranged at the bottom of the funnel 5, and a rotating shaft 504 is connected to the opening 503 through a bearing, and a tooth groove 5041 is arranged at one end of the rotating shaft 504, and a cover is fixedly connected to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com