Mix proportion design method of recycled all-light concrete

A technology of mix ratio design and mix ratio, applied in the field of building materials, can solve the problems of small scope of use, long time consumption, low comprehensive recycling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0198] The prepared recycled all-light concrete is used for building partition wall slat products, the slat strength is MU5, the consistency range is required to be 70-90mm during construction, the set value of the consistency is 70mm, the production level is determined to be general, and the initial setting time is greater than 3 hours. The final setting is greater than 5 hours, and the 28-day compressive strength is ≥5MPa. The prepared recycled light-weight concrete should meet the requirements of relevant specifications, production needs, product performance and reasonable unit price.

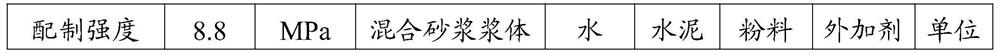

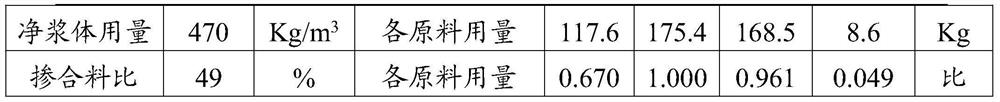

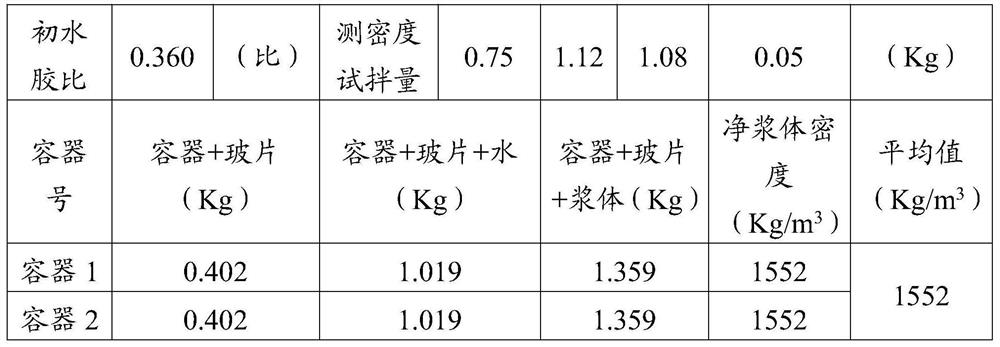

[0199] 1. Initially determine the net slurry and measure the density and air content

[0200] 1. The raw materials for selecting the clean slurry are: cement, water, recycled powder and admixture. The cement is made of Guoda 42.5 cement, and the recycled powder is made of recycled old concrete blocks and discarded bricks (by volume ratio 2:1~3: 1) Mix finely ground powder (particle size 0.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com