Mixing device for foundation raw materials for highway engineering

A mixing device and engineering technology, applied in the field of ground-based raw material mixing devices for highway engineering, can solve the problems of inaccurate mixing ratio and large randomness, and achieve the effects of accurate mixing ratio, reduced pollution, uniform mixing and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

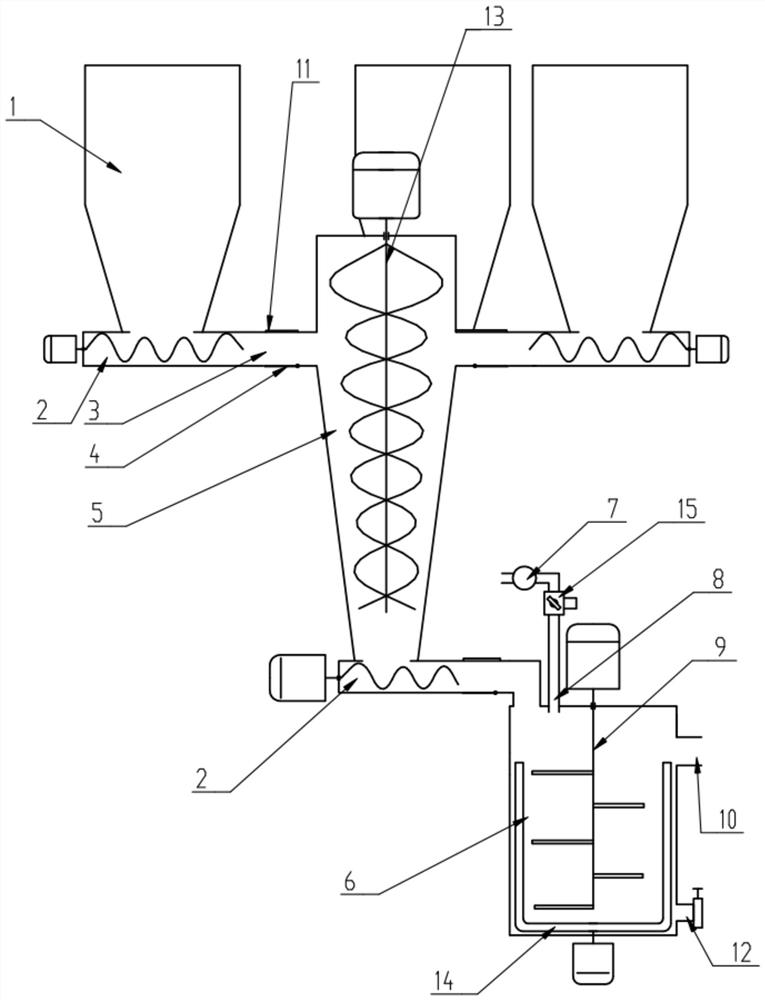

[0023] like figure 1 Shown, a kind of foundation raw material mixing device for highway engineering, it comprises vertical circular mixing barrel 5 and the double ribbon agitator 13 that is arranged in mixing barrel 5, and described mixing barrel 5 bottom is conical, and top is provided with There are three feed ports, each feed port is provided with a set of quantitative feeding unit, and the bottom of the mixing barrel 5 is provided with a discharge port. The lower conical mixing barrel 5 can discharge the mixed raw materials inside it more cleanly. The quantitative feeding unit transports the three raw materials of cement, sand and gravel into the mixing tank 5 in proportion, and is evenly stirred by the double ribbon agitator 13, and is discharged from the discharge port at the bottom of the mixing tank 5, ensuring that the three raw materials The ratio of the ratio avoids the problem of randomness and inaccurate ratio when mixing foundation materials for highway engineer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com