A Greening Structure Applicable to Uneven and Steep Slopes

A technology for steep and side slopes, applied in the field of slope regreening, can solve the problems of increasing the difficulty of vegetation root growth, the bottom of the planting tank cannot be touched, and the vegetation is difficult to attach and survive stably, so as to achieve stable and efficient regreening and ensure survival The effect of high efficiency and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

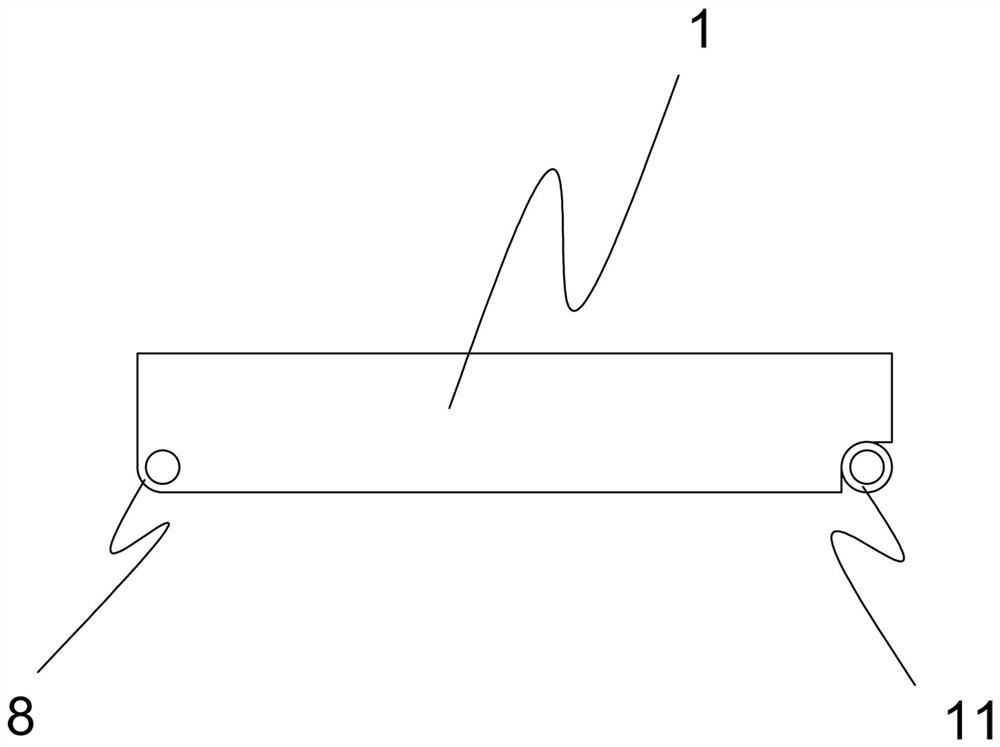

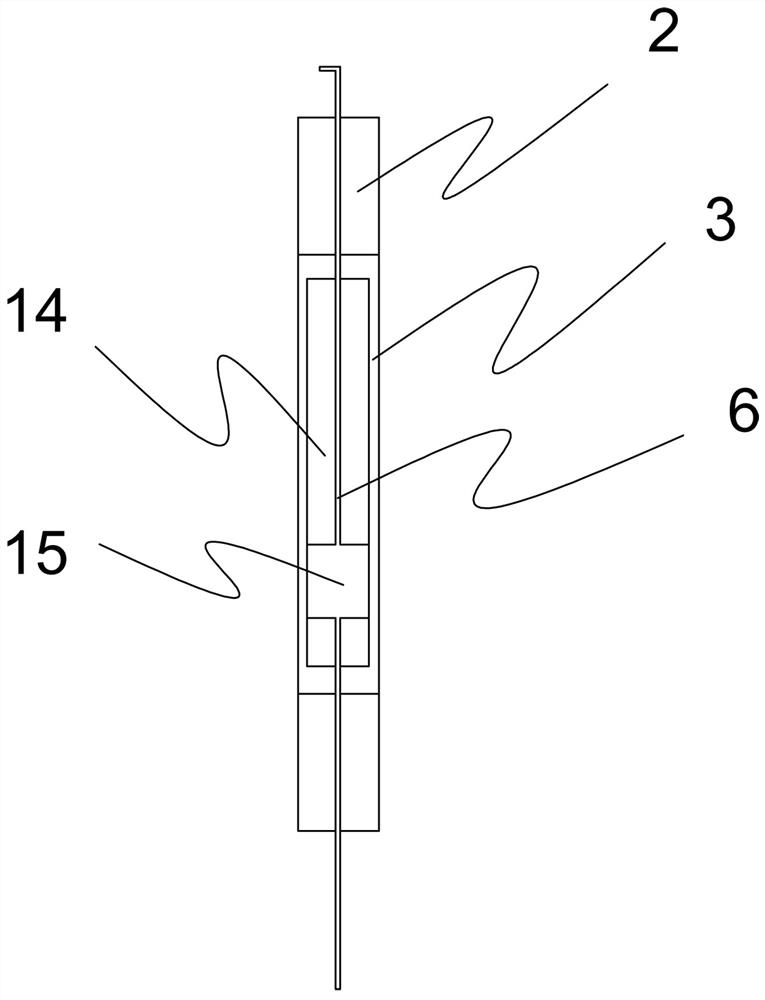

[0022] see figure 1 , figure 2 , image 3 , Figure 4 . A greening structure suitable for uneven and steep slopes according to the present invention, comprising: planting trough coamings 1, rotating shafts arranged between planting trough coamings 1, anchor rods 6, and two adjacent planting trough coamings 1 can rotate around the axis of the rotating shaft, the rotating shaft includes the first rotating shaft assembly 3 and the second rotating shaft assembly 2 sleeved on the first rotating shaft assembly 3, the anchor rod 6 runs through the rotating shaft and the anchor rod 6 can reciprocate in the axial direction of the rotating shaft , the anchor rod 6 and the first rotating shaft assembly 3 remain relatively stationary, when the first rotating shaft assembly 3 rotates, the anchor rod 6 can rotate with the first rotating shaft assembly 3, and the end of the anchor rod 6 away from the ground is fixed with a limit rod 7. The limit rod 7 can be clamped on the second shaft ...

Embodiment 2

[0025] see figure 1 , figure 2 , image 3 , Figure 4 . A greening structure suitable for uneven and steep slopes according to the present invention, comprising: planting trough coamings 1, rotating shafts arranged between planting trough coamings 1, anchor rods 6, and two adjacent planting trough coamings 1 can rotate around the axis of the rotating shaft, the rotating shaft includes the first rotating shaft assembly 3 and the second rotating shaft assembly 2 sleeved on the first rotating shaft assembly 3, the anchor rod 6 runs through the rotating shaft and the anchor rod 6 can reciprocate in the axial direction of the rotating shaft , the anchor rod 6 and the first rotating shaft assembly 3 remain relatively stationary, when the first rotating shaft assembly 3 rotates, the anchor rod 6 can rotate with the first rotating shaft assembly 3, and the end of the anchor rod 6 away from the ground is fixed with a limit rod 7. The limit rod 7 can be clamped on the second shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com