Dome granary facilitating deep sampling of inspection robot

A technology for inspection robots and granaries, applied in the field of inspection robots, can solve problems such as the inability to collect samples of grain, and achieve the effects of easy popularization and application, stability maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

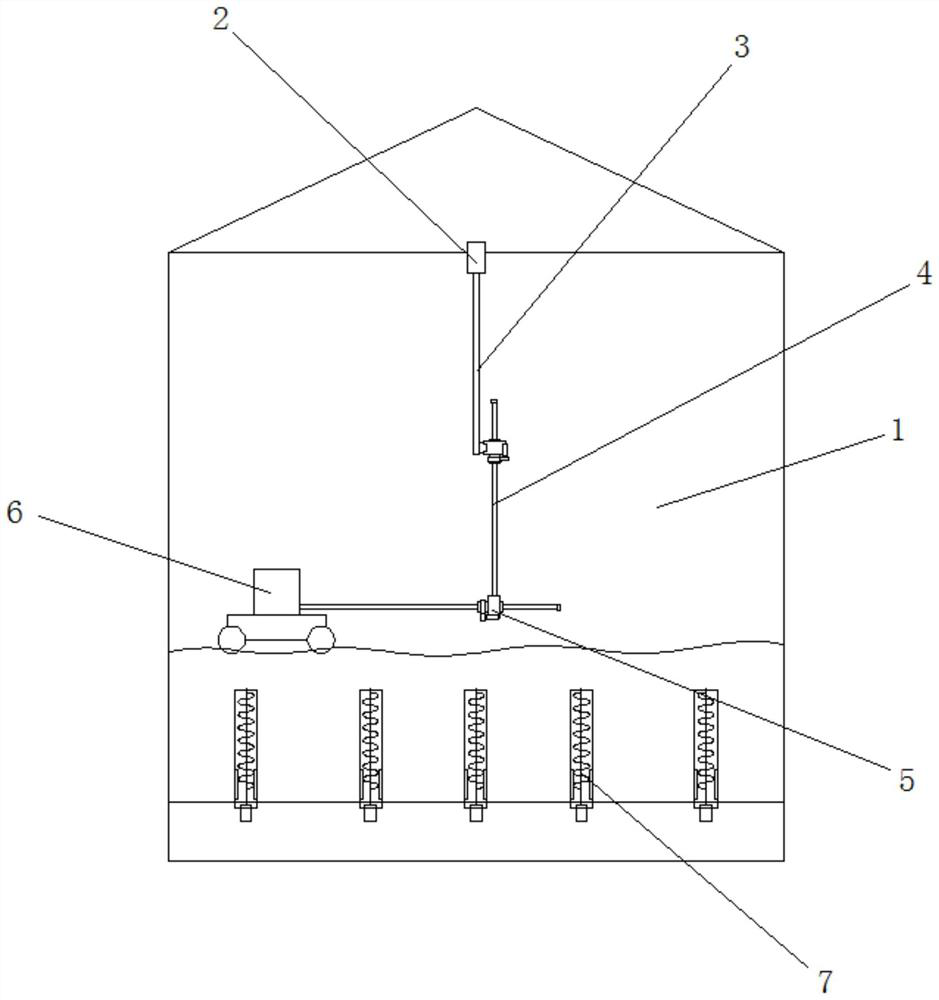

[0026] Embodiment 1: as Figure 1-6 As shown, a dome granary that facilitates deep sampling by inspection robots includes a granary 1, the granary 1 is cylindrical, and a bearing 2 is fixedly installed on the top of the inner cavity of the granary 1, and the bottom of the bearing 2 rotates A rotating shaft 3 is connected, an adjusting mechanism is fixedly installed at the bottom end of the rotating shaft 3 , and a patrol car 6 is fixedly installed at the end of the adjusting mechanism.

[0027] The bearing can drive the rotating shaft to rotate, and the adjustment mechanism can change the height and radius of the inspection vehicle. When the inspection vehicle is pushed forward, it can move in a circular motion in the round warehouse under the traction of the adjustment mechanism.

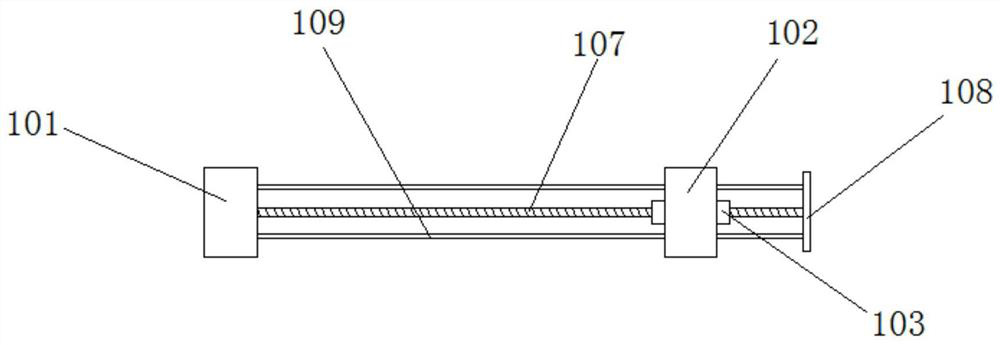

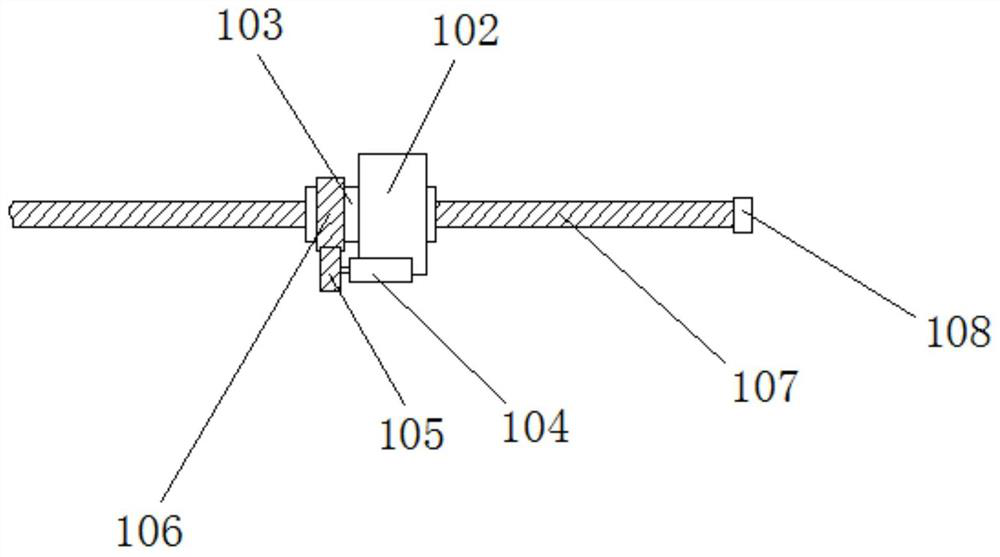

[0028] The adjustment mechanism includes a mounting frame 101 and an adjustment frame 102, the inner cavity of the adjustment frame 102 is provided with an internal threaded drum 103, the outer wal...

Embodiment 2

[0037] Embodiment 2: as Figure 1-7 As shown, a dome granary that facilitates deep sampling by inspection robots includes a granary 1, the granary 1 is cylindrical, and a bearing 2 is fixedly installed on the top of the inner cavity of the granary 1, and the bottom of the bearing 2 rotates A rotating shaft 3 is connected, an adjusting mechanism is fixedly installed at the bottom end of the rotating shaft 3 , and a patrol car 6 is fixedly installed at the end of the adjusting mechanism.

[0038] The bearing can drive the rotating shaft to rotate, and the adjustment mechanism can change the height and radius of the inspection vehicle. When the inspection vehicle is pushed forward, it can move in a circular motion in the round warehouse under the traction of the adjustment mechanism.

[0039] The adjustment mechanism includes a mounting frame 101 and an adjustment frame 102, the inner cavity of the adjustment frame 102 is provided with an internal threaded drum 103, the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com