A double chain sprocket for high torque transmission

A double-row sprocket, high-torque technology, used in belts/chains/gears, transmissions, mechanical equipment, etc., can solve problems such as high noise, fluctuations, and low transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

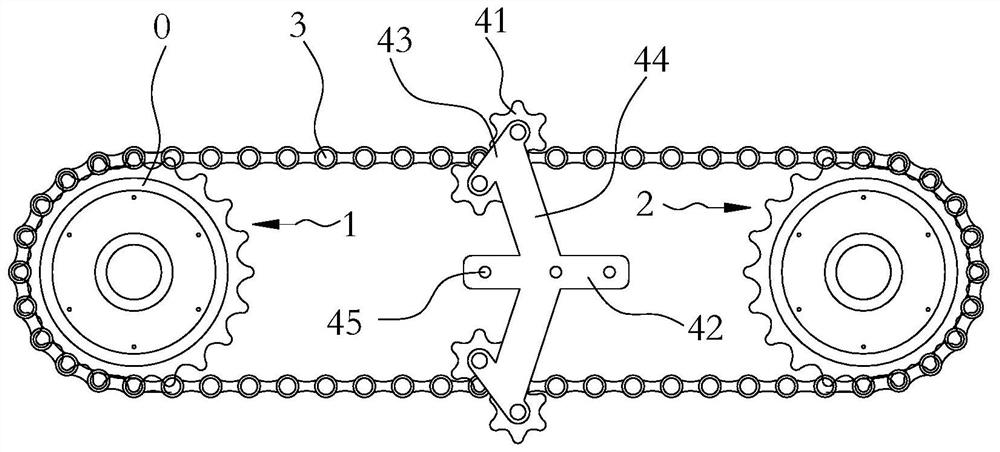

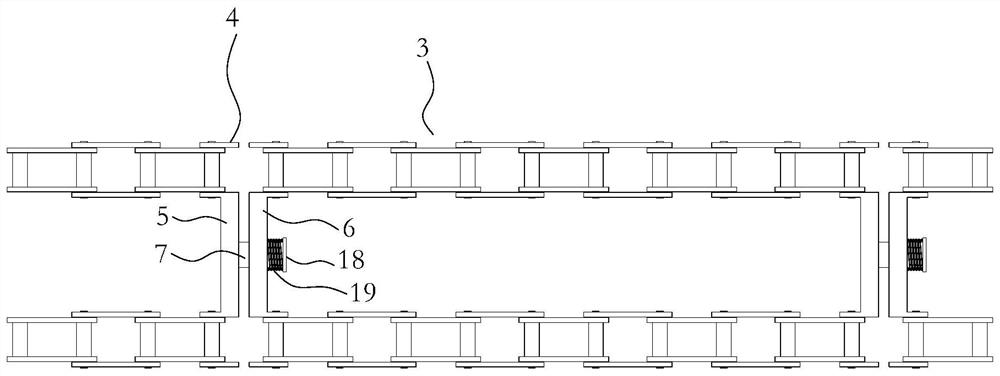

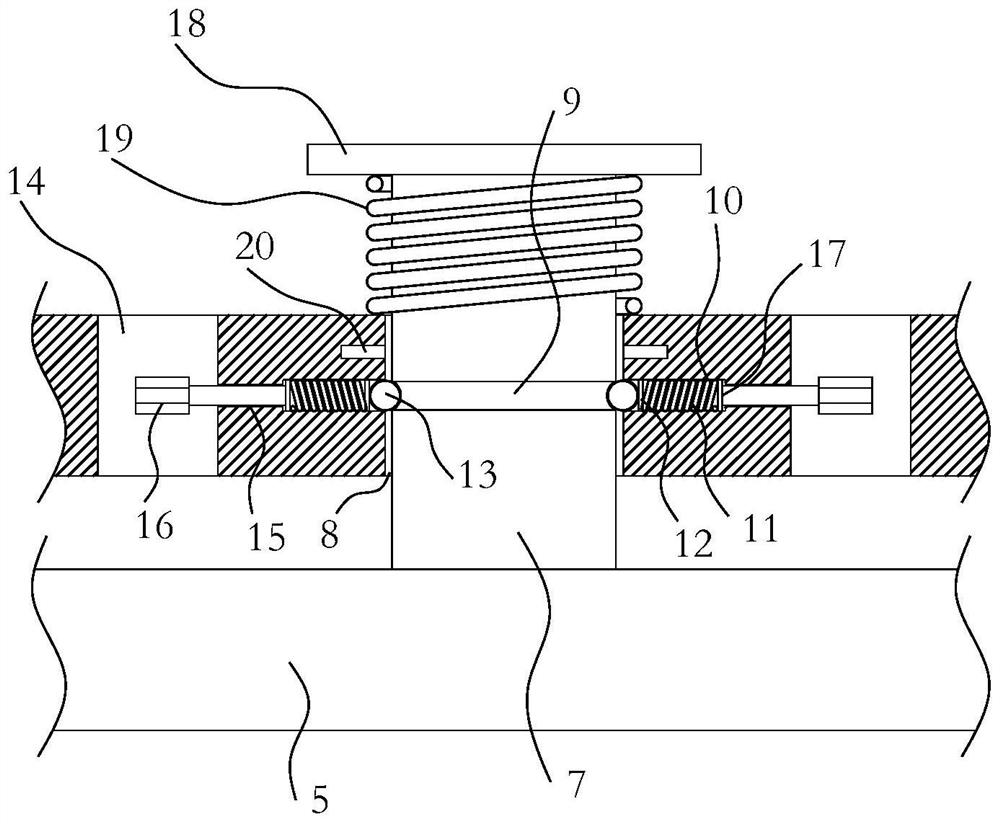

[0029] Such as Figure 1-11 As shown, a sprocket has many advantages such as low noise, good stability, overload protection, suitable for high torque transmission, small transmission fluctuation, etc., and has excellent comprehensive performance indicators. Compared with the traditional chain sprocket transmission combination, the basic structure of the present invention is equivalent to it, and also includes a driving sprocket 1, a driven sprocket 2 and a chain 3, etc., and the chain 3 is formed by connecting several chain links 4, usually A bobbin chain is adopted, and the chain 3 is wound on the gear teeth of the driving sprocket 1 and the driven sprocket 2 .

[0030] But the difference is that the driving sprocket 1 and the driven sprocket 2 of the present invention both include two wheel bodies 0 arranged side by side, adopt a double-row sprocket structure, and the number of the chains 3 is two, two The chains 3 are arranged side by side, and are correspondingly wound on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com