Open hole sealing device

A plugging device and open hole technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of limited cement plug strength, long cycle, low isolation strength, etc., and achieve simple and convenient sealing layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

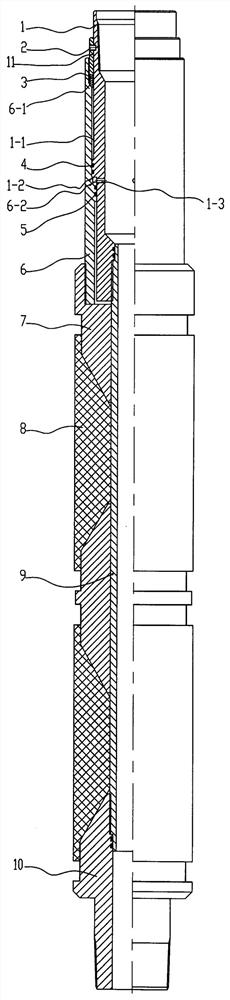

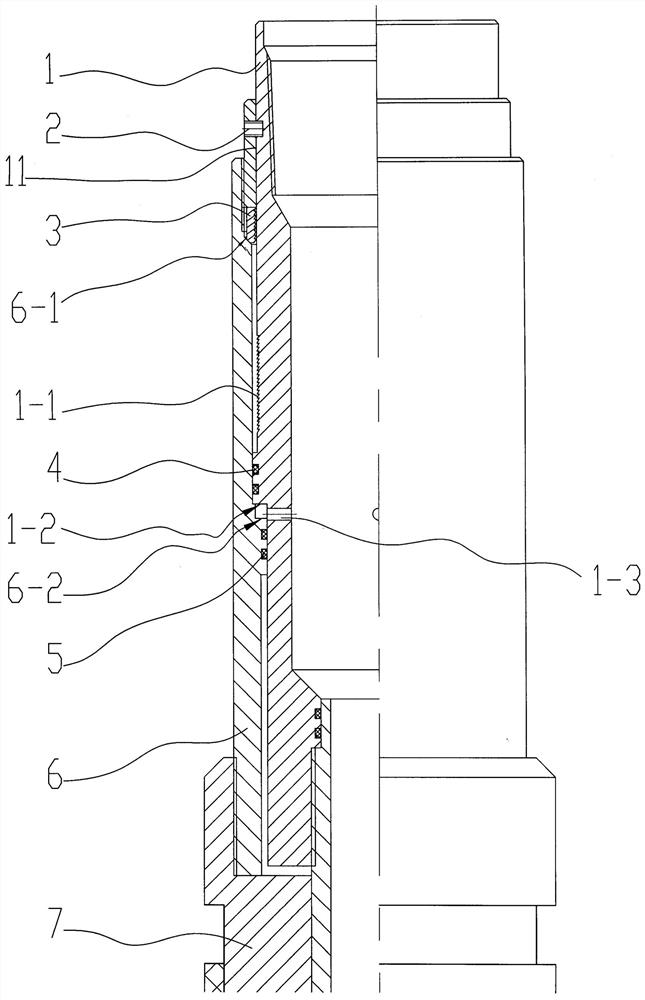

[0010] As can be seen from the figure, the embodiment of the present invention includes a sealed inner tube 1, a constant pressure shear nail 2, a one-way opening lock ring 3, an upper sealing ring 4, a lower sealing ring 5, a sealing outer tube 6, an upper cone 7, and a rubber tube 8. The inner tube 9, the lower cone 10, the coupling sleeve 11, and the outside of the sealed inner tube 1 has an outer variable-diameter shoulder surface 1-2, and the outer diameter of the outer variable-diameter shoulder surface 1-2 is greater than Below the outer diameter, there is a pressure transmission hole 1-3 on the sealed inner tube 1, and the pressure transmission hole 1-3 is under the outer variable diameter shoulder surface 1-2, and the outer wall of the sealed inner tube 1 An upper sealing ring 4 is installed on the top, and the upper sealing ring 4 is located on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com