A combined cleaning and sweeping car noise reduction suction port, processing mold and using method of processing mold

A technology for processing moulds, washing and sweeping cars, applied in the direction of manufacturing tools, metal processing equipment, cleaning methods, etc., can solve the problems of large fan airflow noise, etc., achieve the effects of convenient disassembly and installation, reduce manufacturing costs, and scientific and reasonable processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

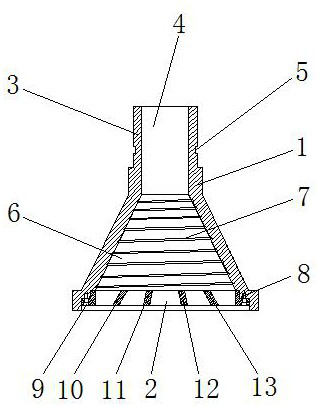

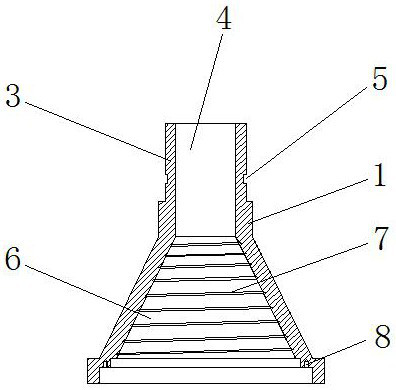

[0041] Such as Figure 1-7 As shown, a combined noise-reducing suction port of a washing and sweeping vehicle, the noise-reducing suction port is composed of a suction port base 1, a suction port cover plate 2 and a spoiler; Composition; the bellows connecting wall 3 outside the airflow channel 4 is provided with a clamp groove 5, the inner wall of the airflow suction port 6 is provided with a spiral groove 7, and the bottom surface of the airflow suction port 6 is provided with a cover plate groove 14, and inside the cover plate groove 14 The suction port cover 2 is connected, and the interior of the suction port cover 2 is provided with a first spoiler 10, a second spoiler 11, a third spoiler 12 and a fourth spoiler 13 from left to right. The spoiler 10 is set at 120° with the horizontal direction of the suction port, the second spoiler 11 is set at 100° with the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com