Blocking forging device and forging process for special-shaped fuel injector body

A technology of blocking forging and injector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

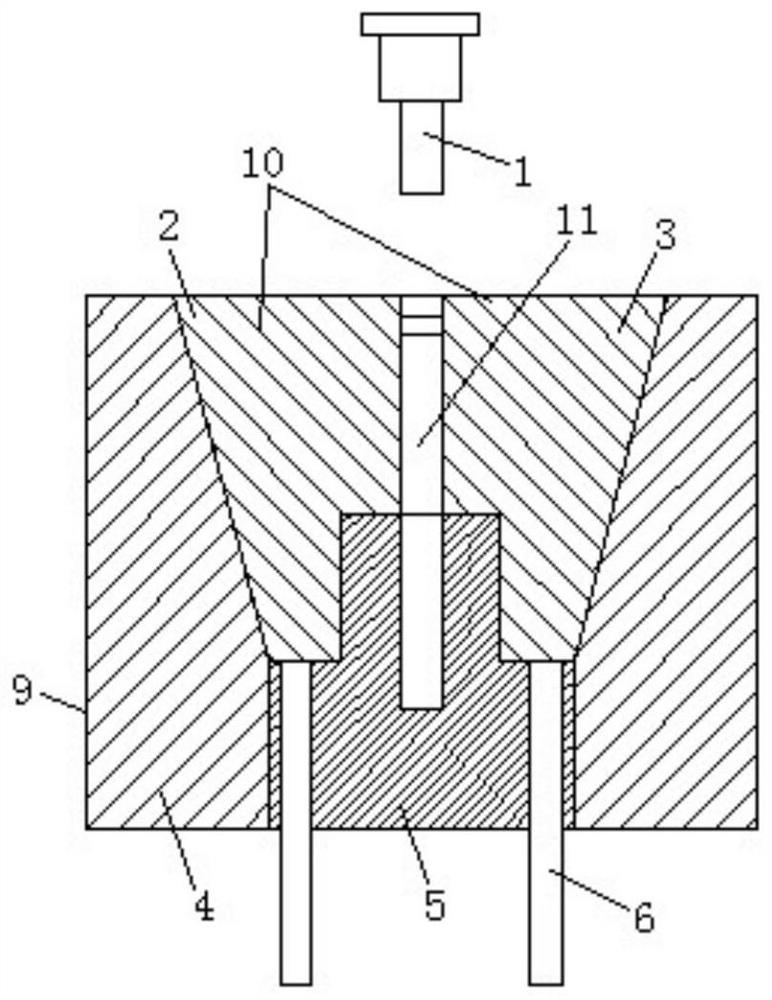

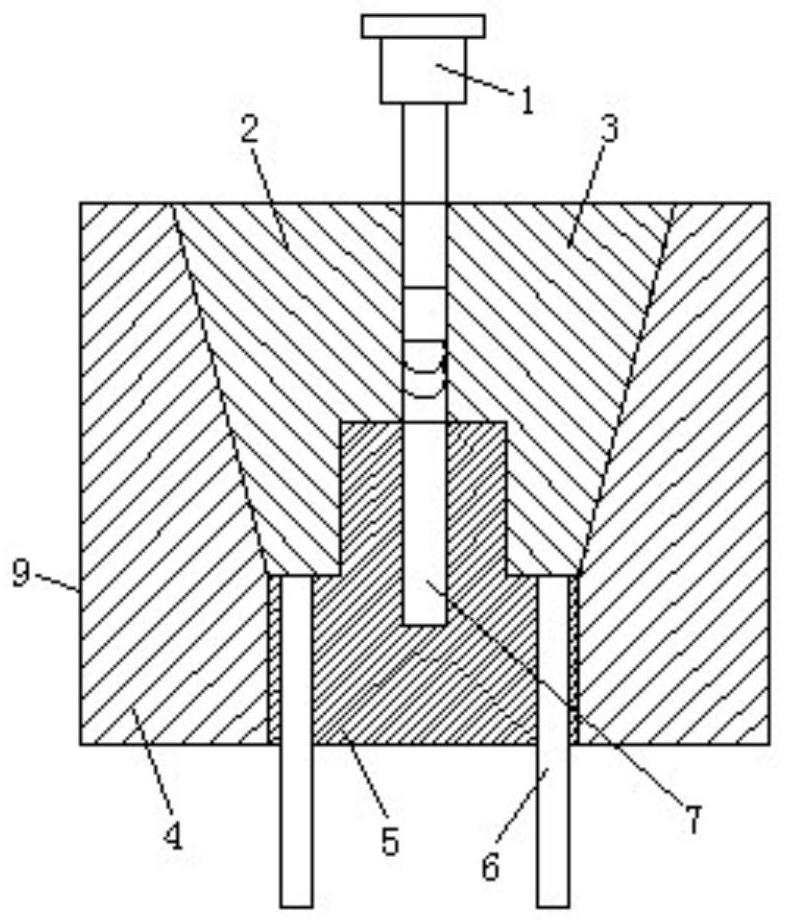

[0038] A closed forging process for a special-shaped fuel injector body,

[0039] The block forging device including any one of the above-mentioned special-shaped injector bodies, the main process includes 6 steps:

[0040] Step 1: The blank 11 is preheated after precise sawing and blanking, sprayed with lubricant, heated to temperature again, and ready to be put into the forming lower mold 9;

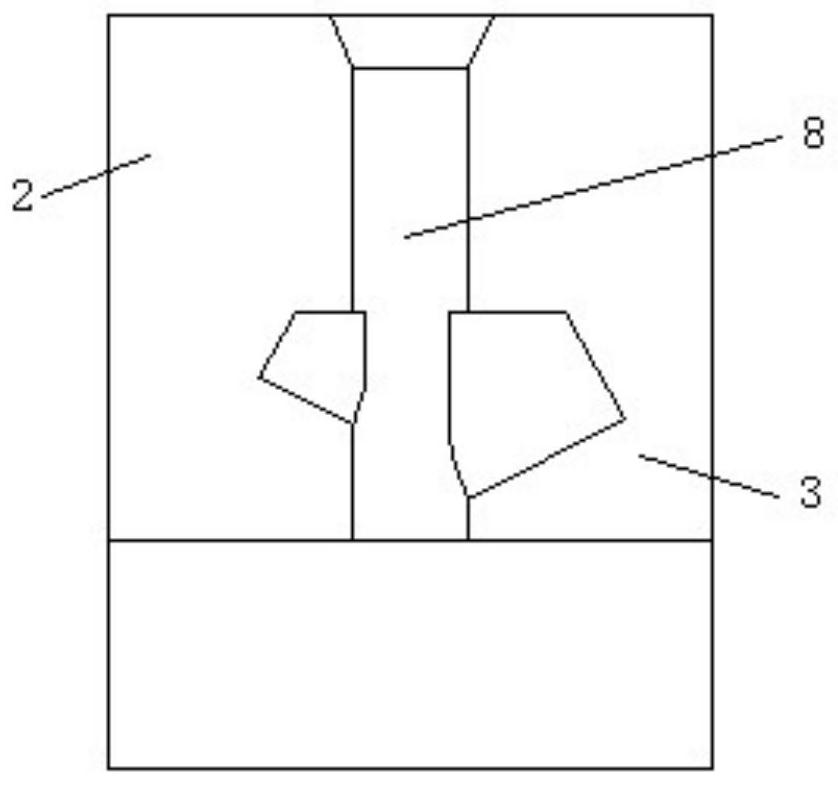

[0041] Step 2: Clamp the left half mold 2 and the right half mold 3 and combine with the base 5 to form a complete molding cavity 8;

[0042] Step 3: Put the blank 11 into the forming lower mold 9 in step 2, and the upper mold 1 presses down the blank 11 along the top of the forming cavity 8 to forge the blank 11;

[0043] Step 4: The upper die 1 is pressed in place, and the blank 11 is filled with the forming cavity 8 to complete the forming and become the forging 7;

[0044] Step 5: After the forming is completed, the upper mold 1 moves upward and separates from the forming lower m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com