Color matching device for powder coating production

A technology for powder coating and toning drum, which is applied to mixers with rotary stirring devices, transportation and packaging, mixer accessories, etc., can solve problems such as affecting work efficiency, blockage of discharge ports, waste, etc., to improve the deodorization effect. , Improve efficiency and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

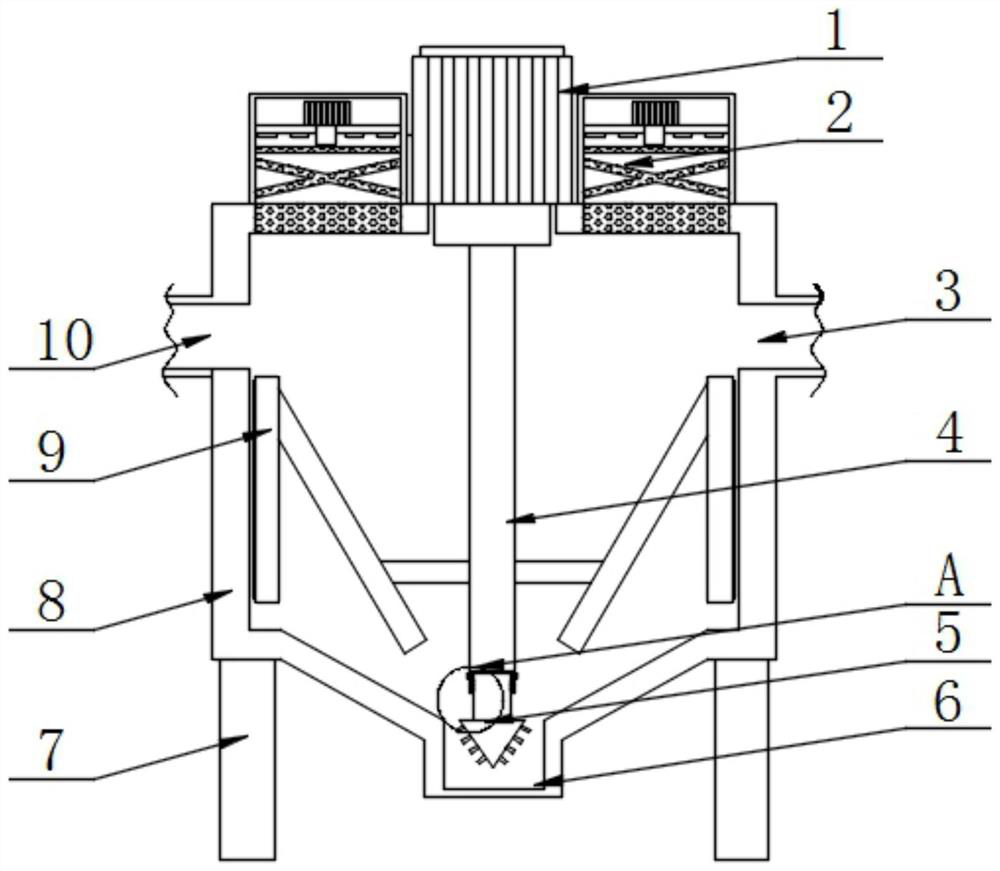

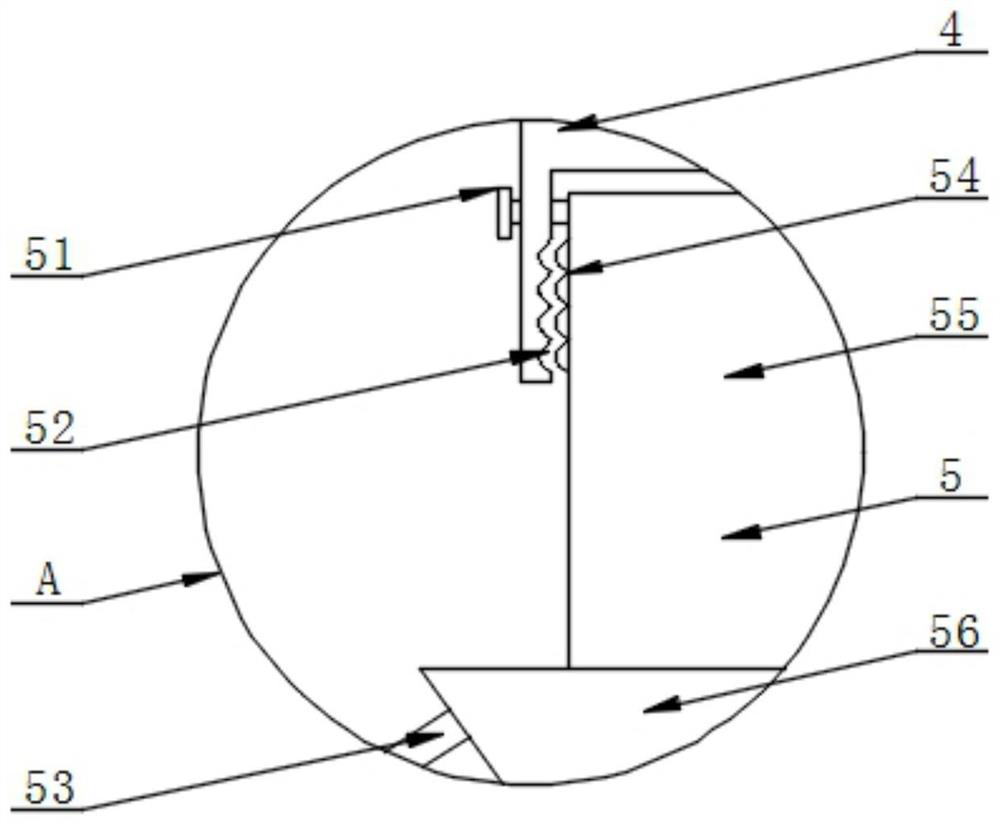

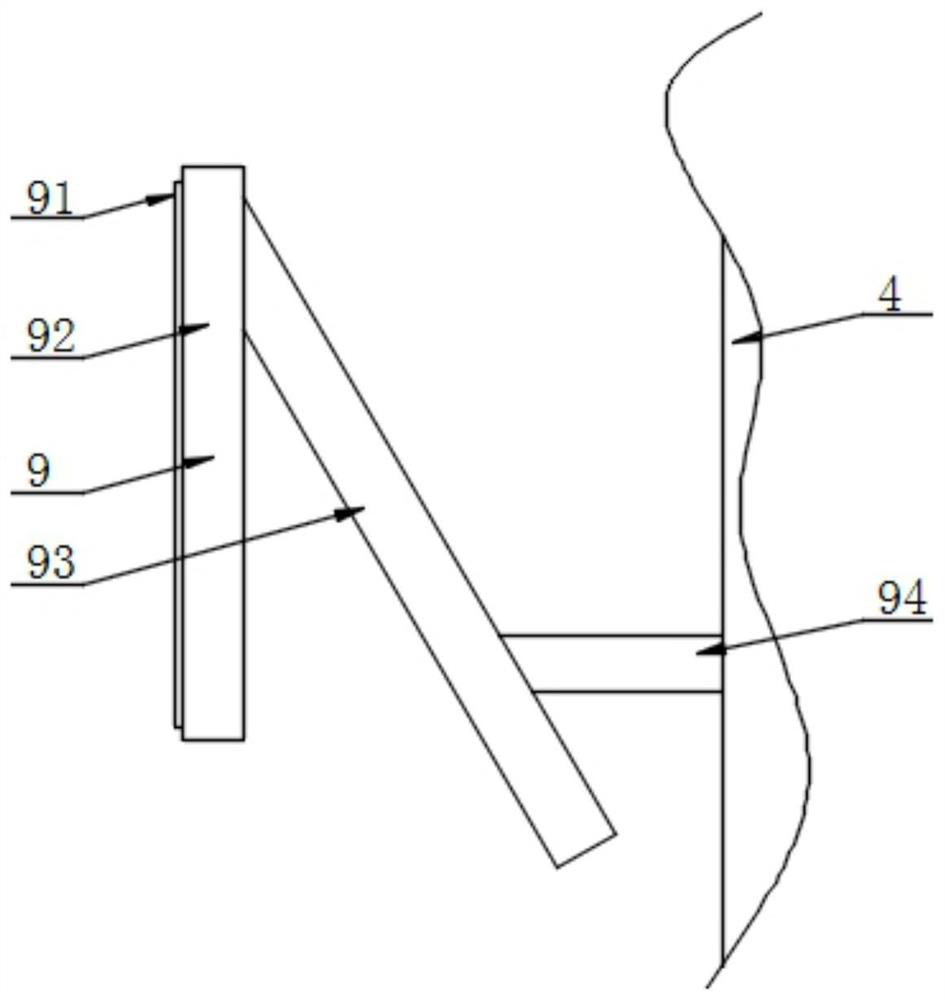

[0024] see Figure 1~5 In an embodiment of the present invention, a color matching device for powder coating production includes a toner tube 8, and the two sides of the toner tube 8 are respectively equipped with a second feed port 10 and a first feed port 3 from left to right, And the bottom of the toner tube 8 is welded with a support column 7, the upper surface of the toner tube 8 is fixedly installed with a toning motor 1, the driving end of the toner motor 1 is connected with a rotating shaft 4, and both sides of the rotating shaft 4 are symmetrically installed with The cleaning assembly 9, the cleaning assembly 9 comprises a scraper 91, a cleaning plate 92, a baffle plate 93 and a connecting rod 94, one end of the connecting rod 94 is affixed to one side of the baffle plate 93, and one end of the connecting rod 94 is arranged on the side of the baffle plate 93. One-third of the position, and the connecting rod 94 and the baffle plate 93 are set at an angle of 135°, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com