Formwork fixing structure for shear wall at narrow expansion joint

A formwork fixing and shear wall technology, which is applied in formwork/formwork/work frame, building structure, and on-site preparation of building components, can solve the problems of unstable center of gravity of formwork in shear walls, affecting construction, etc. Achieve the effect of reducing the possibility of dumping and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

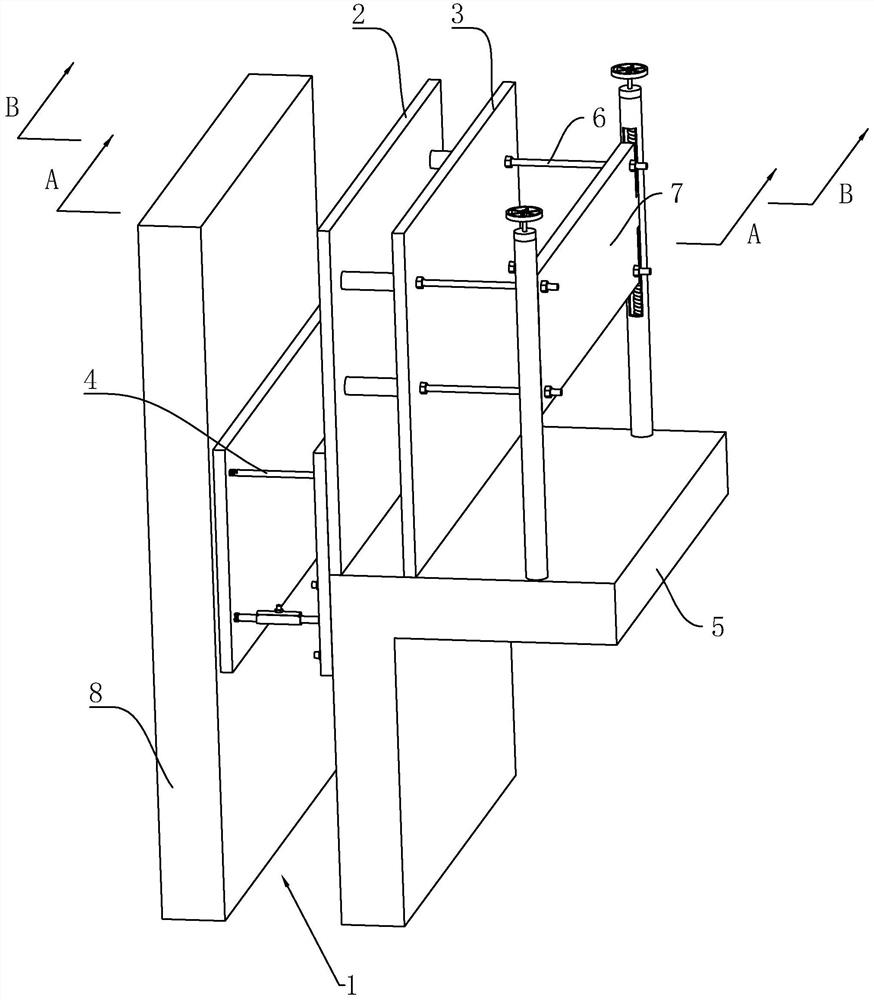

[0041] refer to figure 1 , a formwork fixing structure for a shear wall at a narrow expansion joint, which includes a fixing assembly 3 arranged in an expansion joint 1 and used to limit the formwork 2 in the shear wall, the formwork 2 in the shear wall and the shear wall The outer formwork 4 of the force wall is provided with a connection assembly 6 for installing the inner formwork 2 of the shear wall and the outer formwork 4 of the shear wall on the top wall of the lower concrete 5 .

[0042] refer to figure 1 , the top wall of the lower concrete 5 is provided with a support frame 7, the support frame 7 is connected with the connecting assembly 6, and the support frame 7 is located on the side of the shear wall inner formwork 2 away from the shear wall outer formwork 4; during construction, first place the The fixing component 3 is installed in the expansion joint 1, and then the shear wall inner formwork 2 is installed on the top wall of the lower concrete 5, the shear wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com