Excavator bucket tooth structure

An excavator bucket tooth and excavator technology, which is applied in the field of excavator bucket teeth, can solve the problems of difficult replacement, difficult structure of bucket teeth and tooth sleeves, etc., and achieve the effects of difficult construction, reduced excavation resistance, and reduced shake-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be further described below in conjunction with the drawings in the embodiments of the present invention.

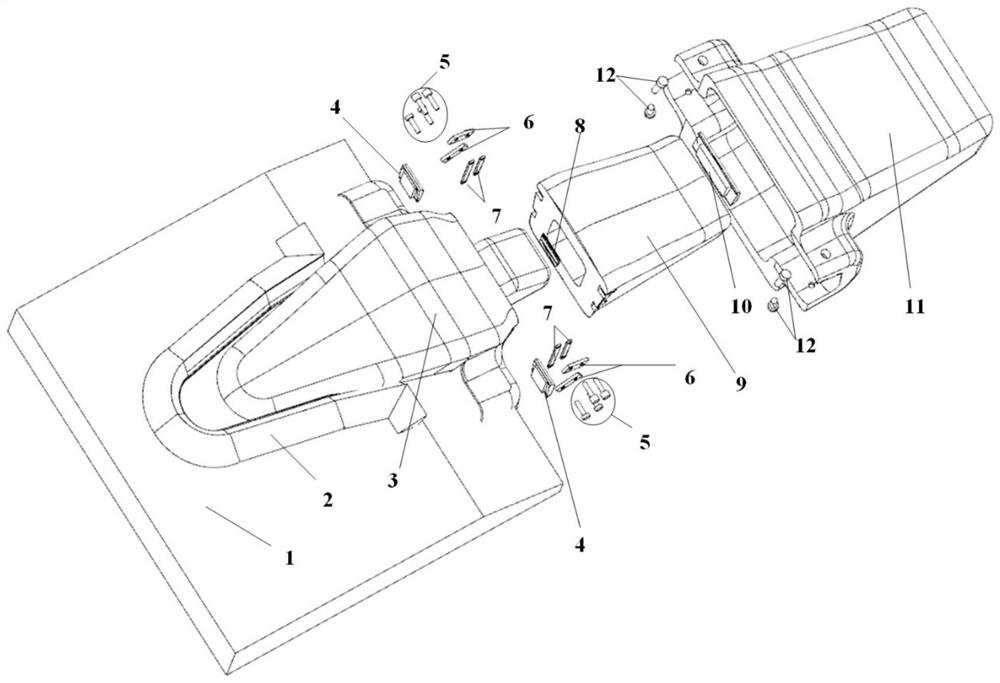

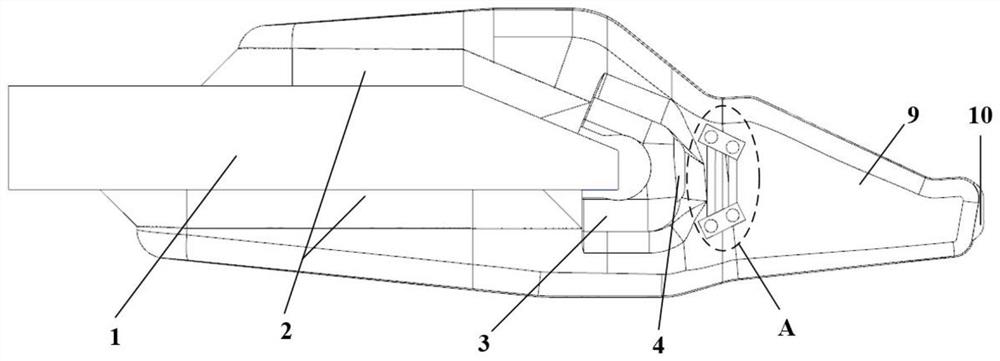

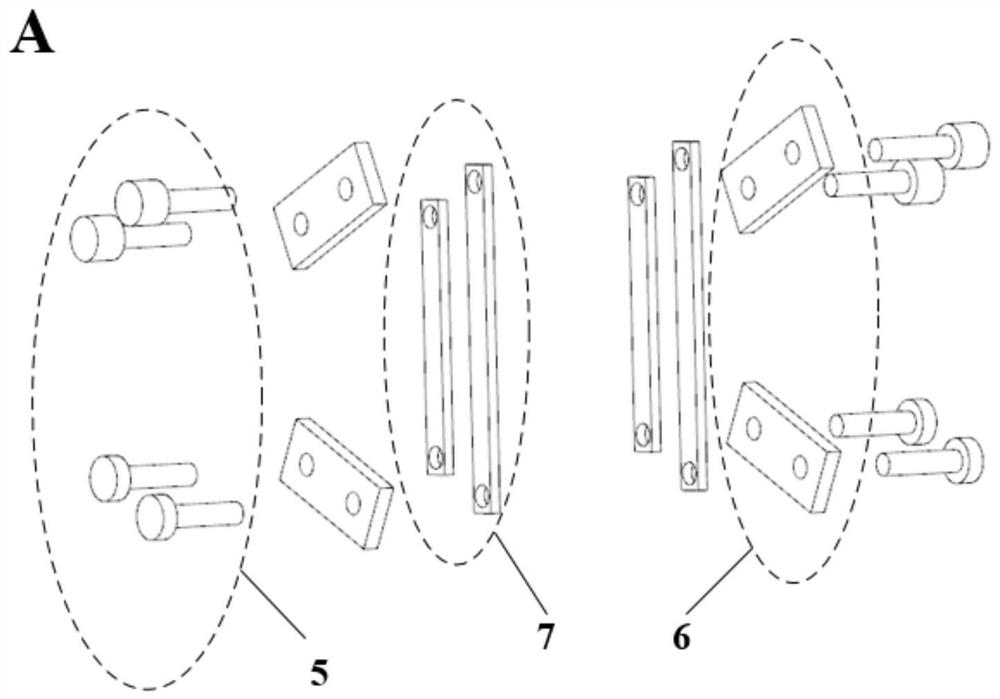

[0018] like figure 1 , figure 2 and Figure 4 As shown, the present invention proposes an excavator bucket tooth structure, including: an excavator bucket tooth structure, including a bucket tooth main structure arranged on the excavator blade 1, the bucket tooth main structure includes a bucket tooth front end 9 and There are two parts at the rear end of the bucket tooth 3, and a part of the rear end 3 of the bucket tooth protrudes forward, so that the joint surface of the front and rear parts of the bucket tooth is larger and can be combined more closely, and it is convenient for pre-installation and fixing of the front end 9 of the bucket tooth. The front end 9 of the bucket tooth is also provided with a tooth sleeve 11 that wraps it as a whole. The tail of the rear end 3 of the bucket t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com