Cast-in-place beam support connecting device and construction process

A connection device and construction technology technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large consumption of welding materials, loss of steel components, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

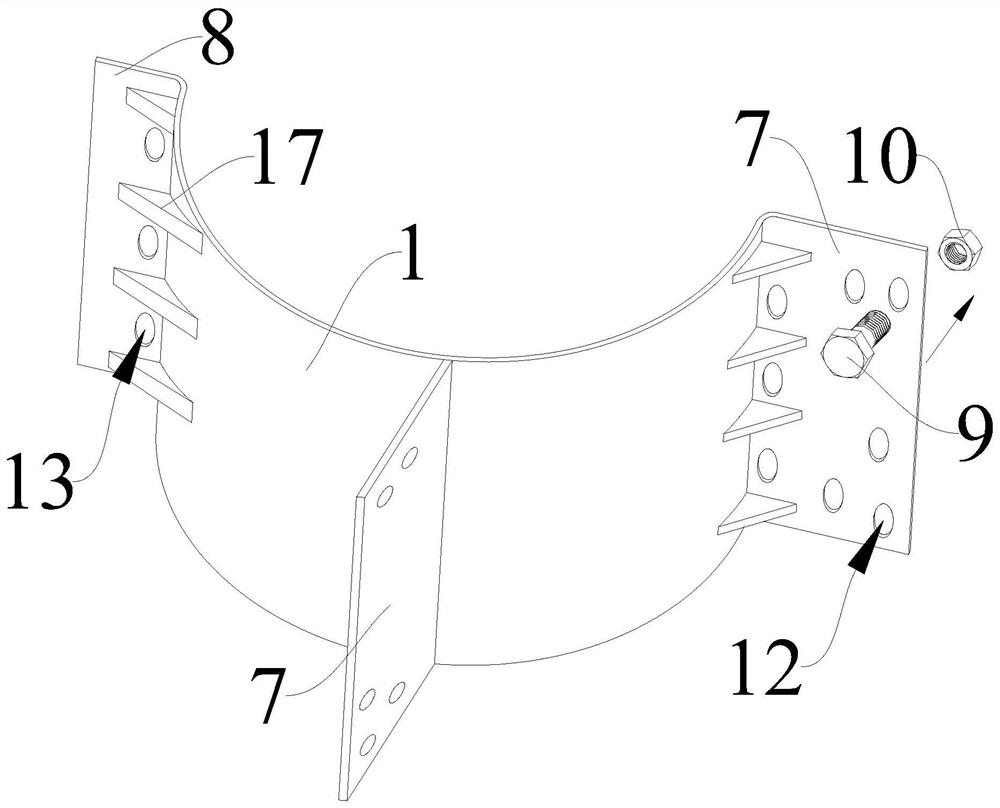

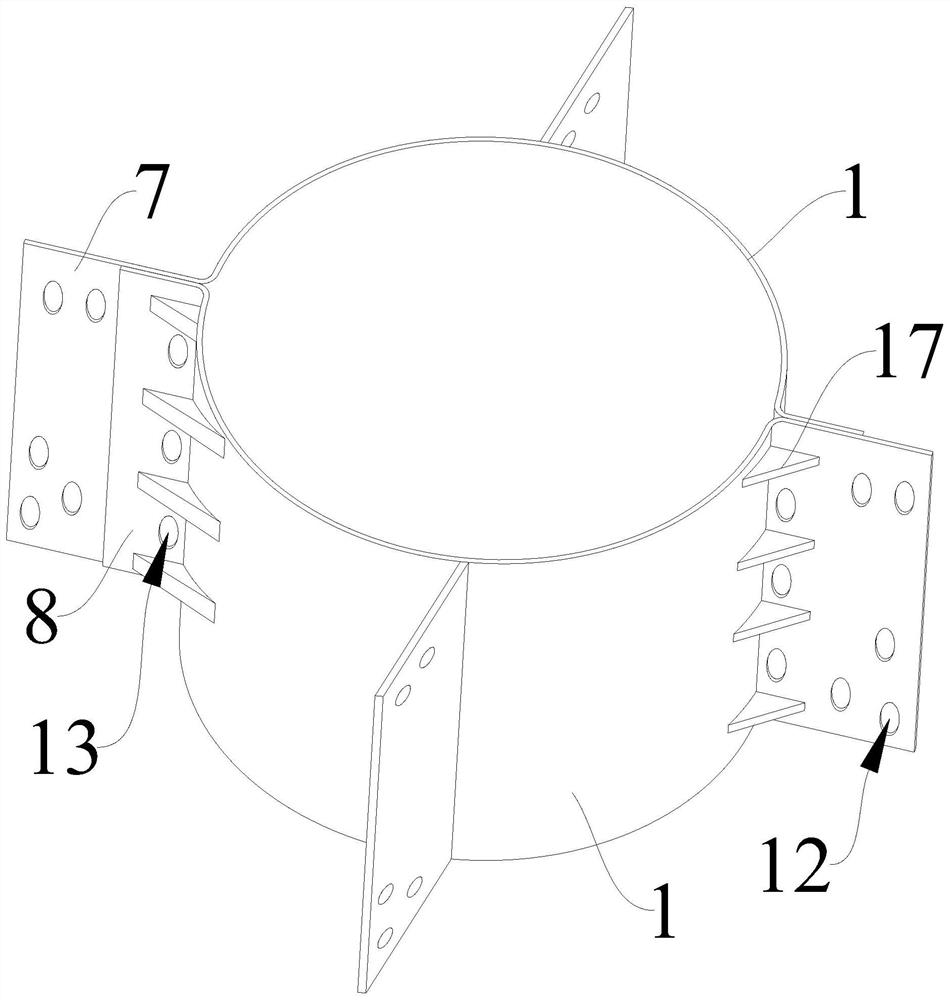

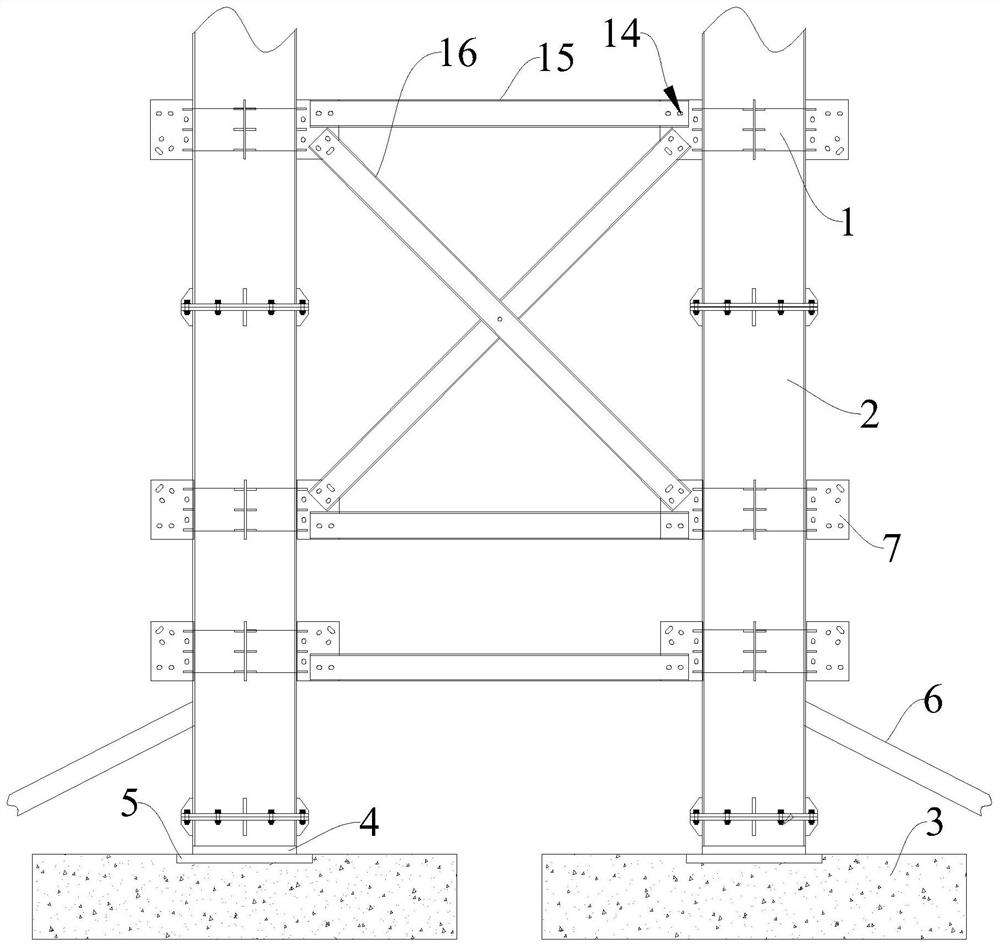

[0039] Please refer to Figure 1-Figure 5 , this embodiment provides a connection device for cast-in-place beam brackets, including a plurality of clamping components and a plurality of connecting components, any clamping component includes a clamping plate 1, and any clamping plate 1 is provided with a first trim plate 7 ; The connection assembly is detachably connected to the first panel 7 . In the present invention, by setting the clamping plate 1, the clamping plate 1 is provided with the first panel 7, and the connection assembly is detachably connected to the first panel 7, so that the two clamping plates 1 can be clamped on the column 2 as a group. The side wall is then connected to the first panel 7 through the connecting component to complete the installation of the bracket, which is convenient to install.

[0040] Such as Figure 1-Figure 5 As shown, in some embodiments of the present invention, the cross-section of the above-mentioned clamping plate 1 is semicircu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com