System and process for finely separating and recycling asphalt pavement milling material

A fine separation and asphalt pavement technology, applied in roads, roads, road repairs, etc., can solve problems such as low quality of recycled materials, rough screening technology and crushing technology, and inability to fully utilize recycled materials for asphalt milling and planing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

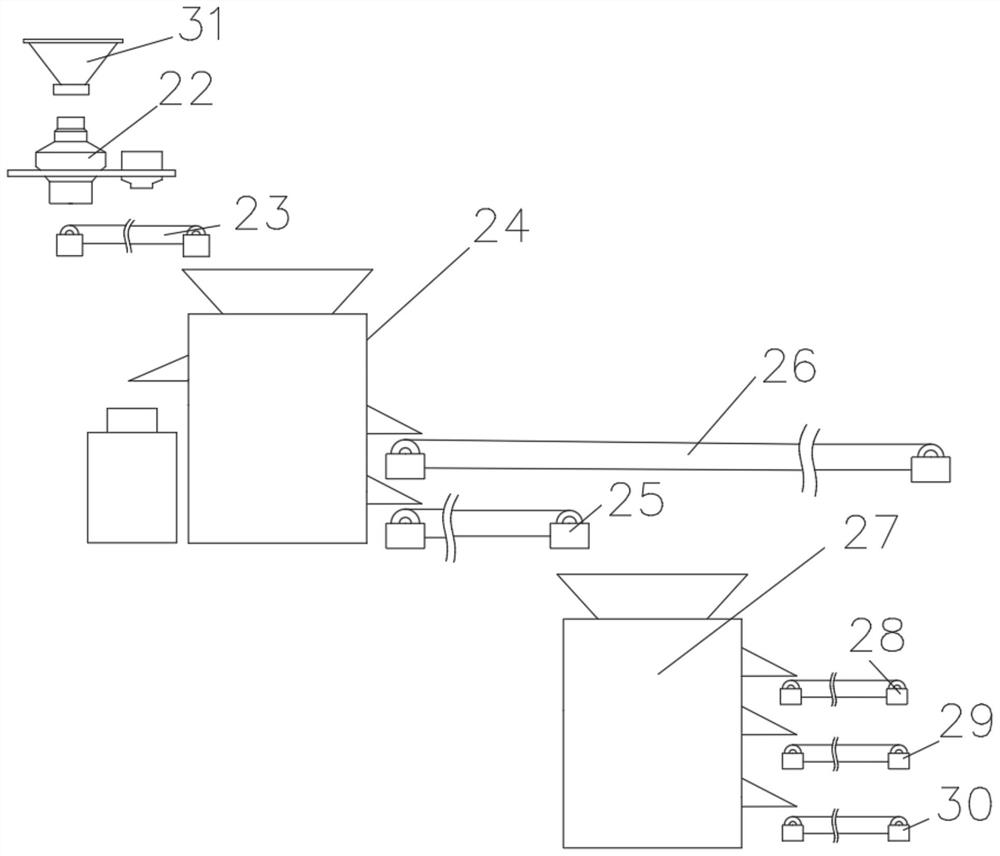

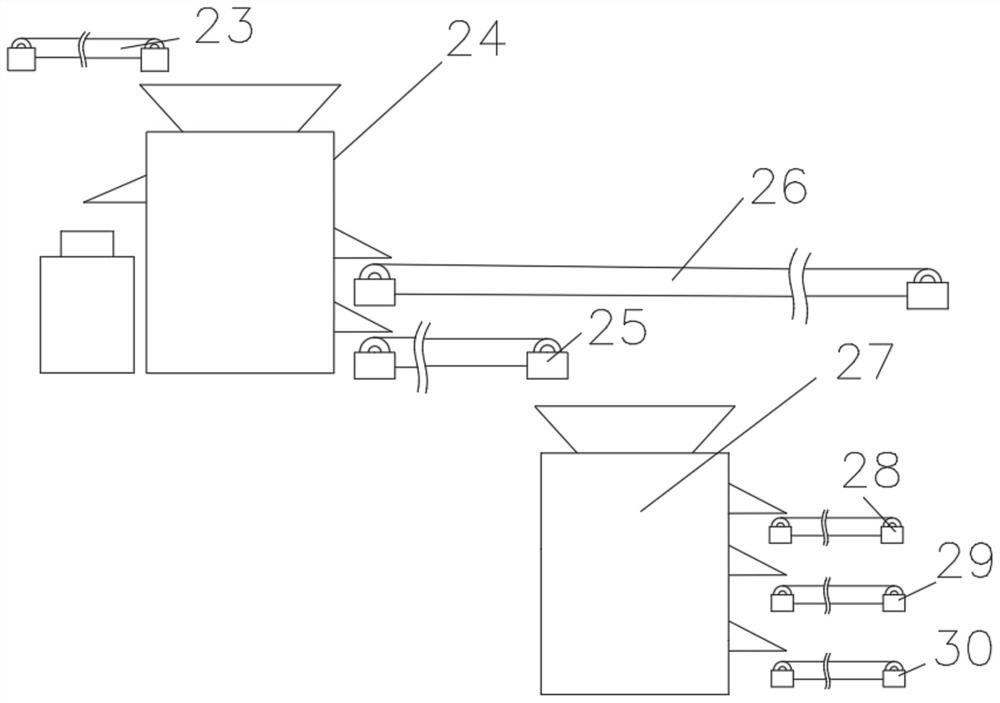

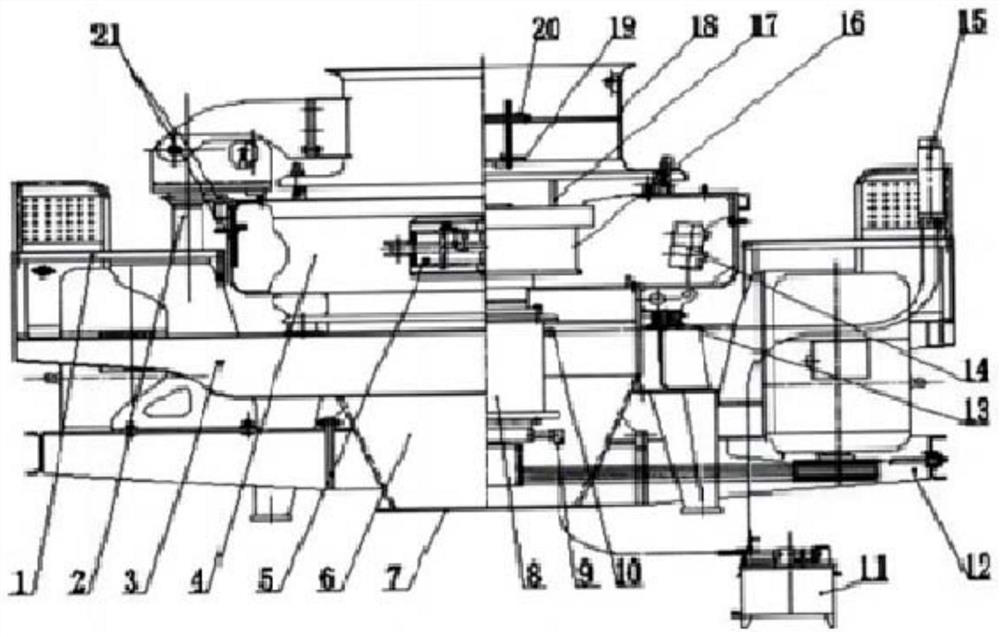

[0040] Example 2: see Figure 1-11 , the present invention provides another technical solution: a fine separation and reuse process of asphalt pavement milling material, the fine separation and reuse process of asphalt pavement milling material is based on the fine separation and reuse of asphalt pavement milling material described in claims 1 to 6 system, the asphalt pavement milling material fine separation reuse process includes:

[0041] The S1 raw material batching bin is used for batching the fine separation box, and the raw material batching bin is used to transport the raw materials to the inside of the fine separation box through the discharge barrel and the feeding hopper, so as to facilitate the fine separation process of the raw materials;

[0042] The S2 fine separation box finely separates the raw materials. The raw materials enter the fine separation box through the feed hopper. At this time, the movable baffle of the bulk material tray turns to the inner side t...

Embodiment 3

[0049] Example 3: See Figure 1-11 , the present invention provides a kind of technical scheme: adopt different fine separation parameters to finely separate asphalt pavement milling and planing reclaimed material (RAP), and the extraction and screening test results after separation are as follows:

[0050] When the processing parameter is 1,

[0051] The specifications of asphalt pavement milling and planing recycled materials (RAP) are between 10-15mm, and the pass rates of raw materials passing through different sizes of sieve holes are 19mm, 100%, 16mm, 99.1%, 13.2mm, 95%, 9.5mm, 38.3 %, 4.75mm, 13.5%, 2.36mm, 10.8%, 1.18mm, 9.1%, 0.6mm, 7.3%, 0.3mm, 6.1%, 0.15mm, 5.1%, 0.0075mm, 4.1%, asphalt content is 3.01% ;

[0052] The specifications of asphalt pavement milling recycled material (RAP) are between 5-10mm, and the pass rate of raw materials passing through different sizes of sieve holes is 19mm, 100%, 16mm, 100%, 13.2mm, 100%, 9.5mm, 95.3 %, 4.75mm, 22.5%, 2.36mm, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com