Fully automatic feeding, coiling and packaging machine

A fully automatic, packaging machine technology, applied in the field of coiling, packaging machines, and fully automatic feeding, can solve the problems of high labor costs, high labor intensity of workers, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

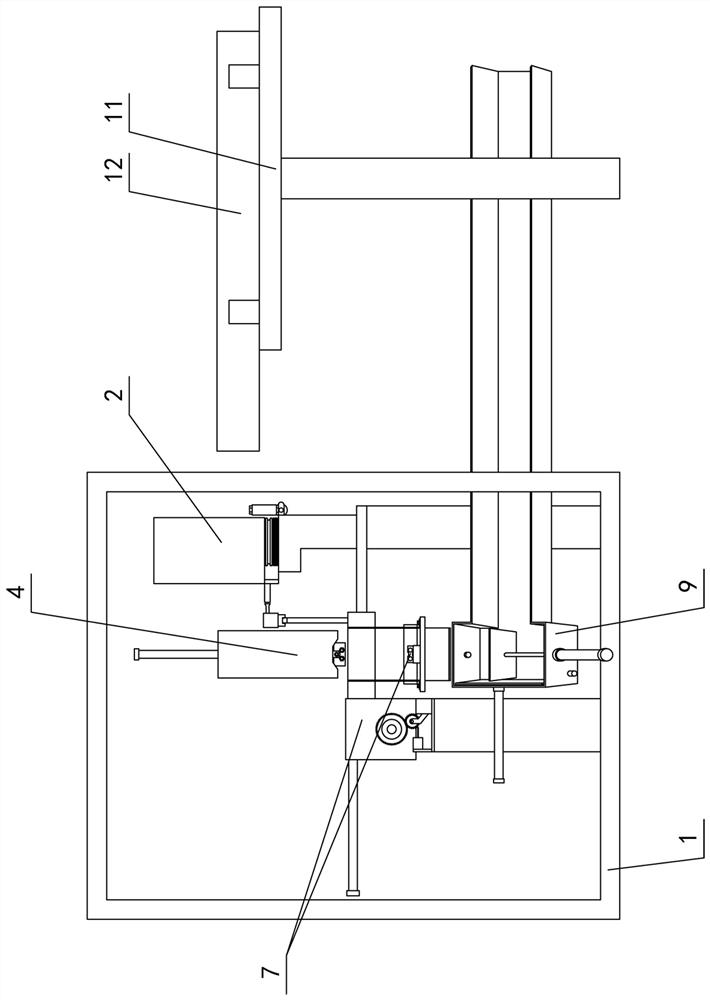

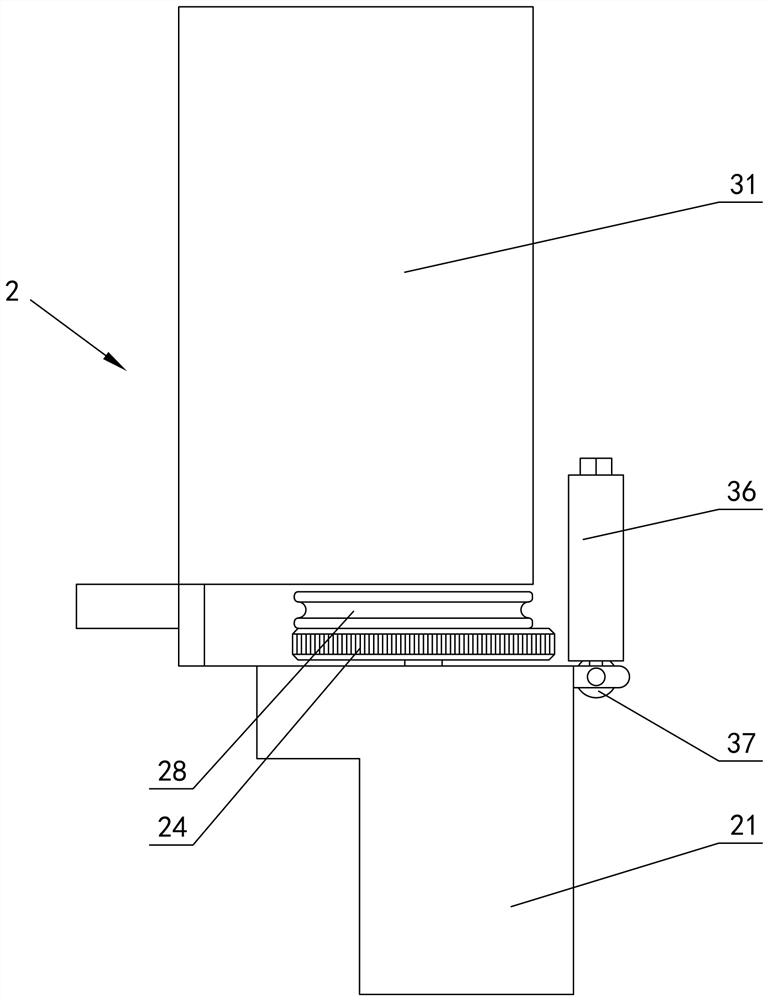

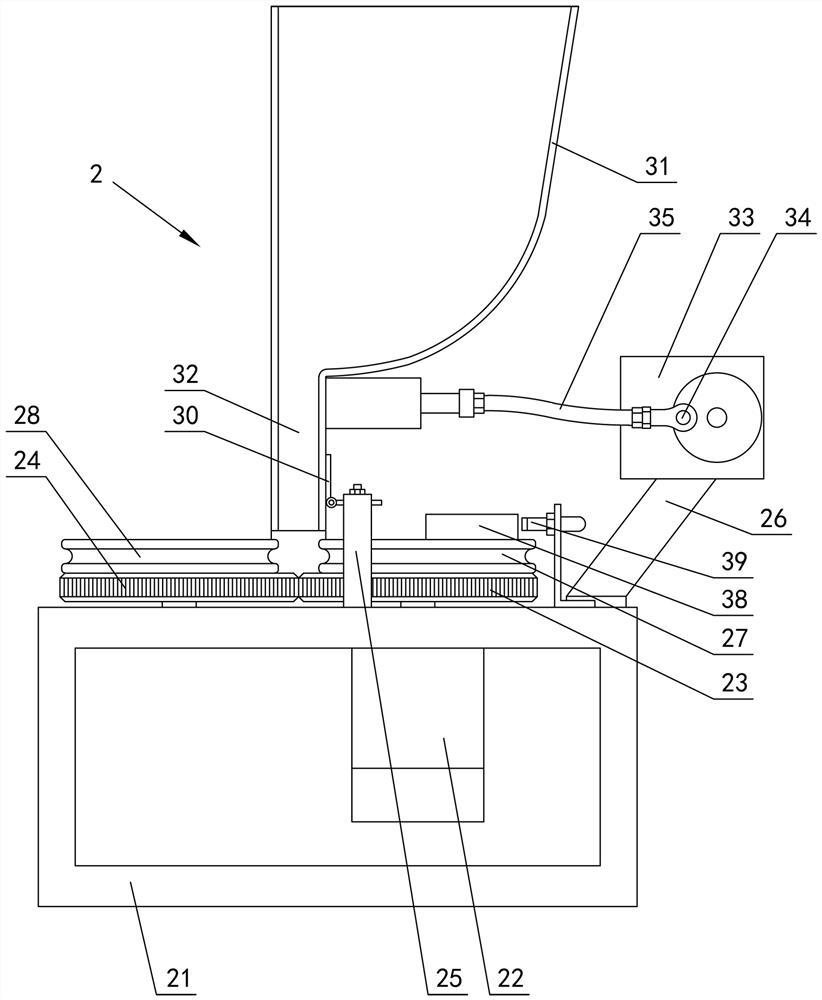

[0026] The present invention relates to a kind of fully automatic feeding, coiling tube, packaging machine, such as figure 1 — Figure 11As shown, it includes a frame 1 and a support frame 11, a material storage tank 12 is arranged on the support frame, pipes are placed in the material storage tank, and a swing type material feeding device 2, a pipe coiling device 4, and a delivery bag are arranged on the frame. Packaging device 7 and collecting and sorting device 9; Described swing type material feeding device 2 comprises material management support 21, and material management support is fixed with frame 1, and feeding motor 22, driving gear 23, from Driven gear 24, swing fixed frame 25 and motor support frame 26, the output shaft of feeding motor 22 connects drive gear 23, and drive gear is meshed with driven gear 24, and active feeding turntable 27 is set on drive gear, and drive gear is set on drive gear. Driven feeding turntable 28, active feeding turntable and the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com