Rolling mill halt controlling method and controlling system thereof

A control system and rolling mill control technology, used in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of low safety factor, waste of materials, inability to achieve accurate shutdown, etc., to improve utilization and safety factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

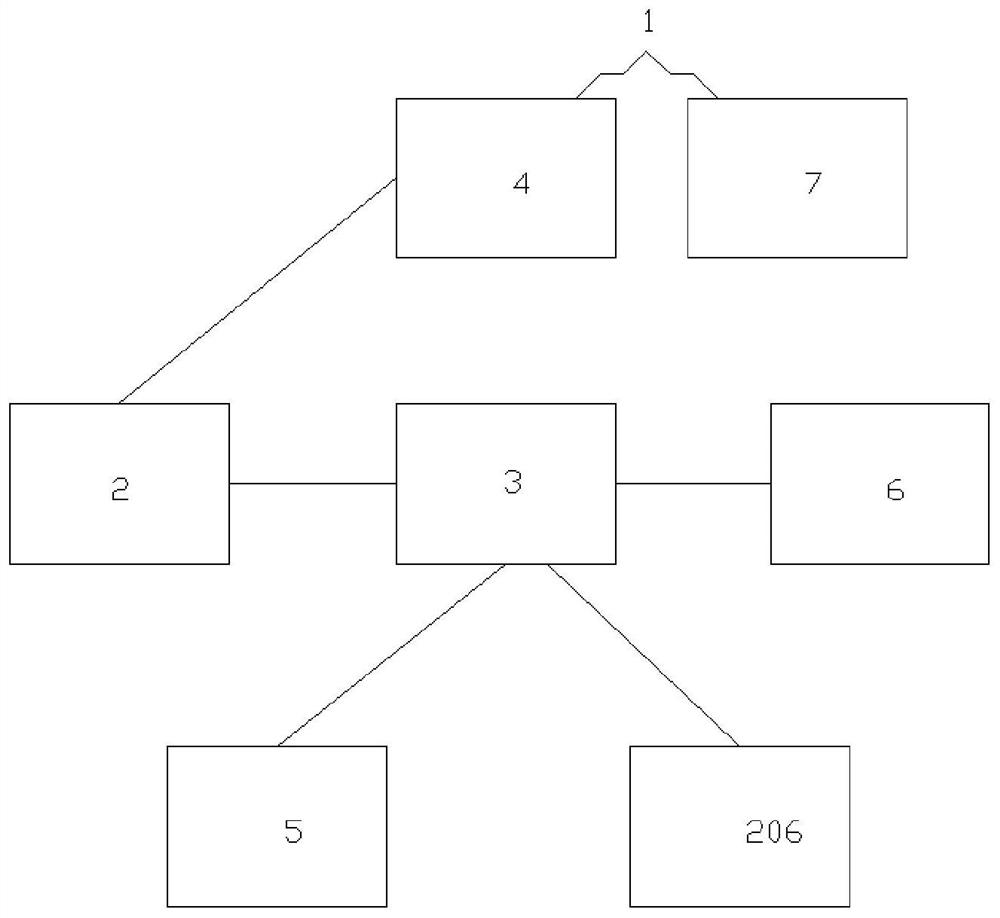

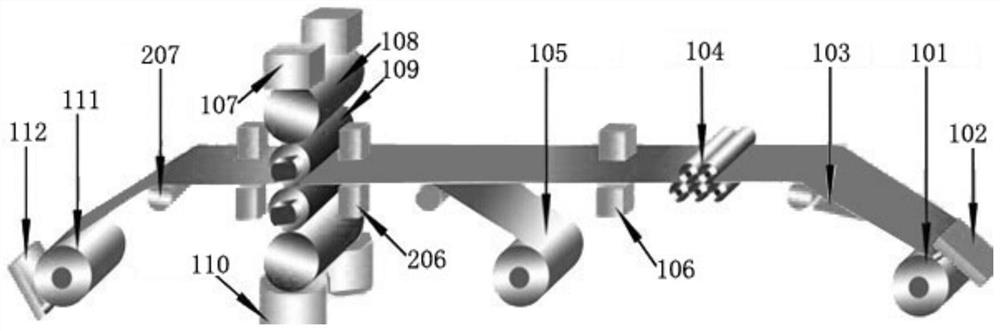

[0023] Such as figure 1 with 2 As shown, the present invention provides a control system for shutting down a rolling mill, including a rolling mill control unit 1, a main control unit 2, a plate thickness control module 3 and an industrial computer 6, and the exit and entrance of the worker roll 109 are equipped with thickness measurement Instrument 206, it also includes the encoder 5 that is used to detect the length of rolling plate, described plate thickness control module 3 is connected encoder 5 and thickness gauge 206 respectively, and described plate thickness control module 3 is connected with industrial control computer 6 And exchange data, the described plate thickness control module 3 sends the order of deceleration to the rolling mill when the length of the worker roll 109 away from the rolling line reaches the remaining length, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com