Material separation method and device, controller and storage medium

A controller and material technology, applied in the direction of sorting, etc., can solve the problems of wrong sorting of materials, lowering the accuracy of material sorting, and the injection of materials into other sorting areas, etc., to achieve accurate sorting and simple control , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

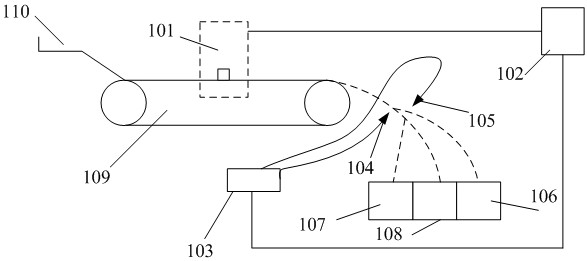

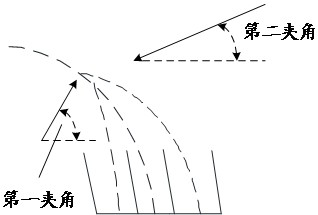

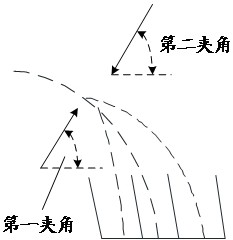

[0052] In order to solve the problem of related technologies, it is necessary to accurately and accurately control the injection force. When the performance of the injection mechanism decreases or the air supply pressure fluctuates, it is easy to cause the injected material to enter other sorting areas, resulting in wrong sorting of the material, reducing the It solves the problem of the accuracy of material sorting. An embodiment of the present invention provides a material sorting system. Two blowing devices are provided, and the blowing direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com