High-resolution full-color Micro LED display

A high-resolution, full-color technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problem that the secondary optical regulation function of the reflective cup cannot be brought into play, achieve high secondary optical regulation, and overcome optical crosstalk , Solve the effect of optical crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

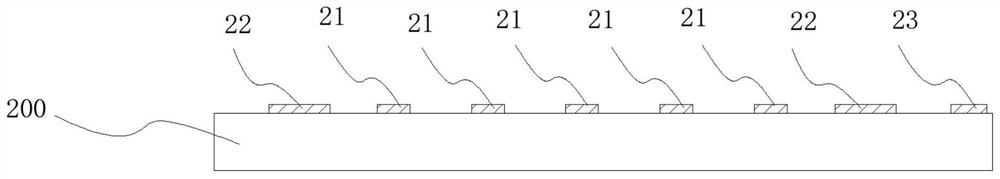

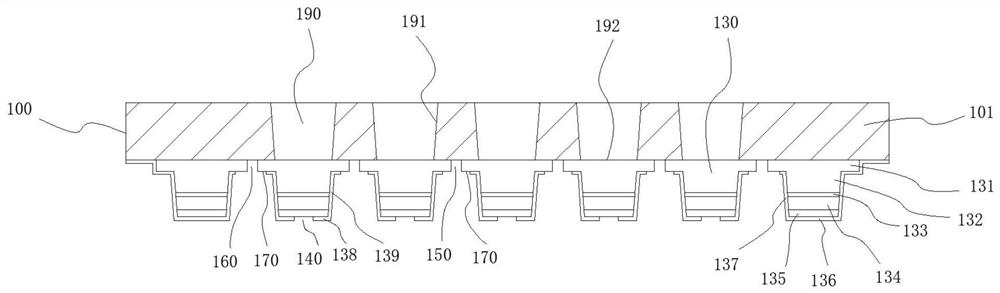

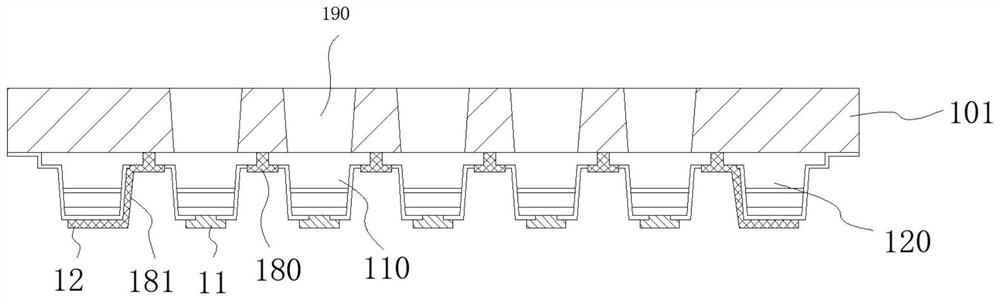

[0058] Please refer to Figure 1 to Figure 6 , a high-resolution full-color MicroLED display, provided with a driving substrate 200, a MicroLED array module 100, the surface on the driving substrate 200 is provided with a first pad 21 and a second pad 22, the lower surface of the MicroLED array module 100 The first electrode 11 and the second electrode 12 are provided, and the lower surface of the MicroLED array module 100 is welded face-to-face with the upper surface of the driving substrate 200, so that the first electrode 11 and the first pad 21 are welded together, and the second electrode 12 Solder with the second pad 22 together.

[0059] The MicroLED array module 100 is provided with MicroLED light-emitting chips 110 and dummy chips 120, and there are several MicroLED light-emitting chips 110, and each MicroLED light-emitting chip 110 is provided with a first electrode 11 on the lower surface, and the second electrode 12 is provided with on the lower surface of the dum...

Embodiment 2

[0083] Please refer to Figure 7 The MicroLED array module 100 is provided with a MicroLED light-emitting chip 110 and a dummy chip 120. There are several MicroLED light-emitting chips 110. A first electrode 11 is provided on the lower surface of each MicroLED light-emitting chip 110. The second electrode 12 It is disposed on the lower surface of the dummy chip 120 . The plurality of Micro LED light-emitting chips 110 are distributed into an array according to a fixed pitch between rows and columns.

[0084] The dummy chips 120 are also provided with several pieces, each dummy chip 120 is provided with a second electrode 12 on the lower surface, and the size of the dummy chips 120 is equal to the size of the MicroLED light-emitting chip 110 . The dummy chip 120 is independent from the dummy chip 120 . The row spacing of the dummy chips 120 is equal to the row spacing of the array of Micro LED light-emitting chips 110 .

[0085] The dummy chips 120 surround the periphery of ...

Embodiment 3

[0088] Please refer to Figure 8 The dummy chips 120 are also provided with several pieces, and the lower surface of each dummy chip 120 is provided with two first electrodes 11 , and the size of the dummy chips 120 is equal to the size of the MicroLED light-emitting chip 110 . The dummy chip 120 is independent from the dummy chip 120 . The row spacing and column spacing of the dummy chips 120 are respectively equal to the row spacing and column spacing of the array of Micro LED light-emitting chips 110 .

[0089] The dummy chip 120 is disposed on the periphery of the array of Micro LED light-emitting chips 110 . The MicroLED array module 100 is square, and the dummy chips 120 are distributed on two of the four outer sides of the MicroLED array module 100 .

[0090] All the other are identical with embodiment two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com