Filter element end cover welding mold with nitrogen fire extinguishing and cooling mechanism

A cooling mechanism and welding mold technology, applied in the field of machinery, can solve the problems of being unable to rotate, without fire extinguishing, etc., and achieve the effects of improving safety, increasing versatility, and increasing diffusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

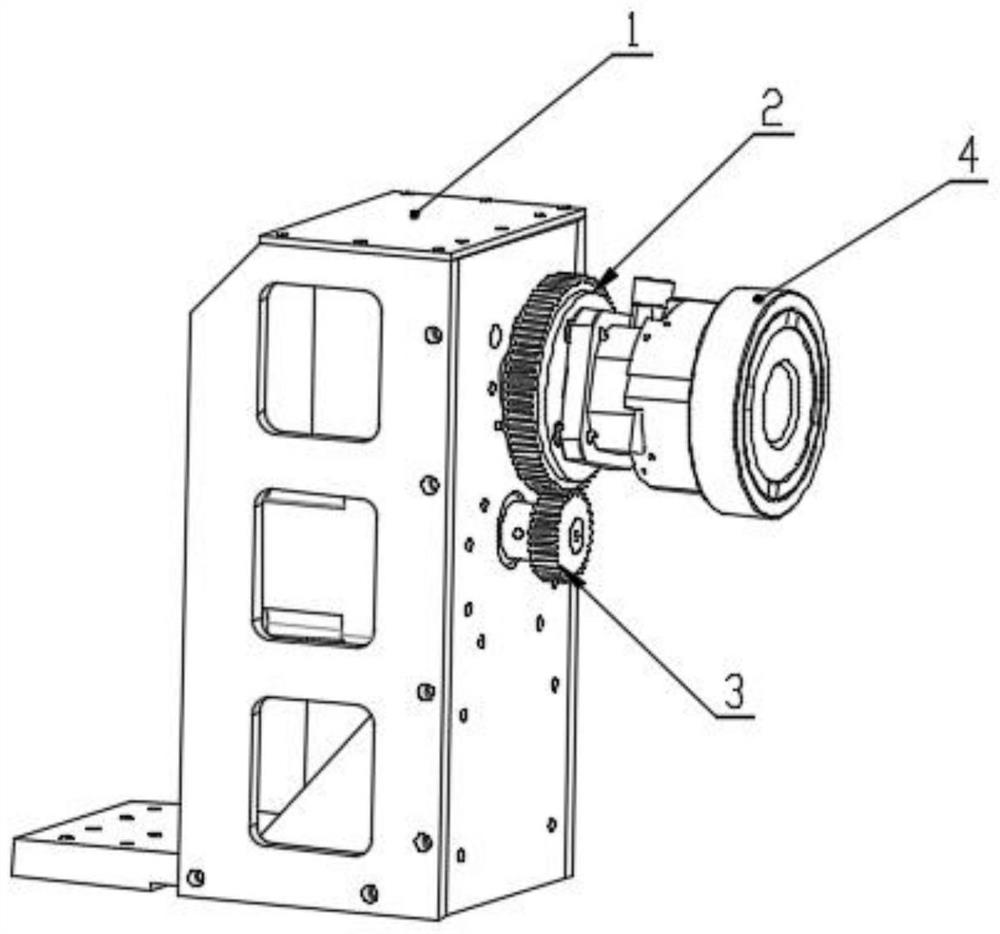

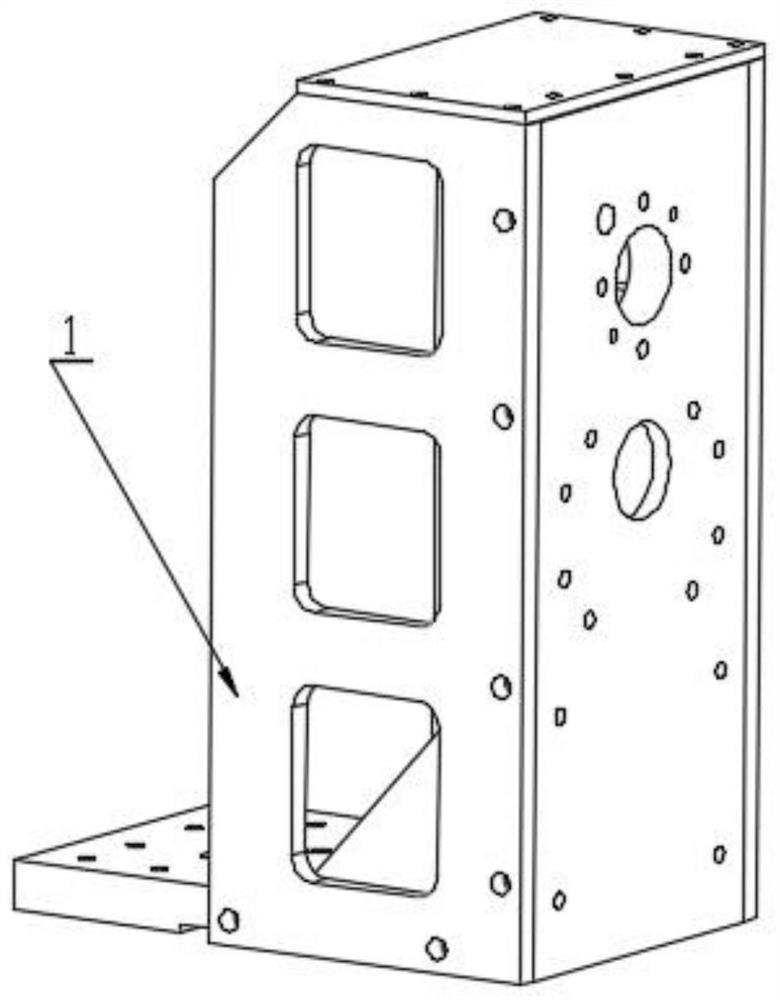

[0054] Specific embodiment 1, see Figure 1 to Figure 9 , the filter element end cover welding mold with nitrogen fire extinguishing and cooling mechanism includes an installation mold 4 for installing the filter element end cover, the installation mold 4 is provided with an installation groove for installing the filter element end cover 42, and also includes a frame assembly 1, Mold rotation assembly 2 and mold motor assembly 3.

[0055] The mold motor assembly 3 is installed on the frame assembly 1 . The mold motor assembly 3 includes a driving motor 31 and a driving gear 32 installed on the rotating shaft of the driving motor 31 .

[0056]The mold rotating assembly 2 includes a supporting shaft 21, a driven gear 22, a screw rod 24, a spring 25 and a mold fixing member 26. The supporting shaft 21 is installed on the frame assembly 1, and the supporting shaft 21 is rotationally connected with the driven gear 22 through a bearing 23. , the driven gear 22 meshes with the driv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com