A hot-bending protective forming process for cover plate

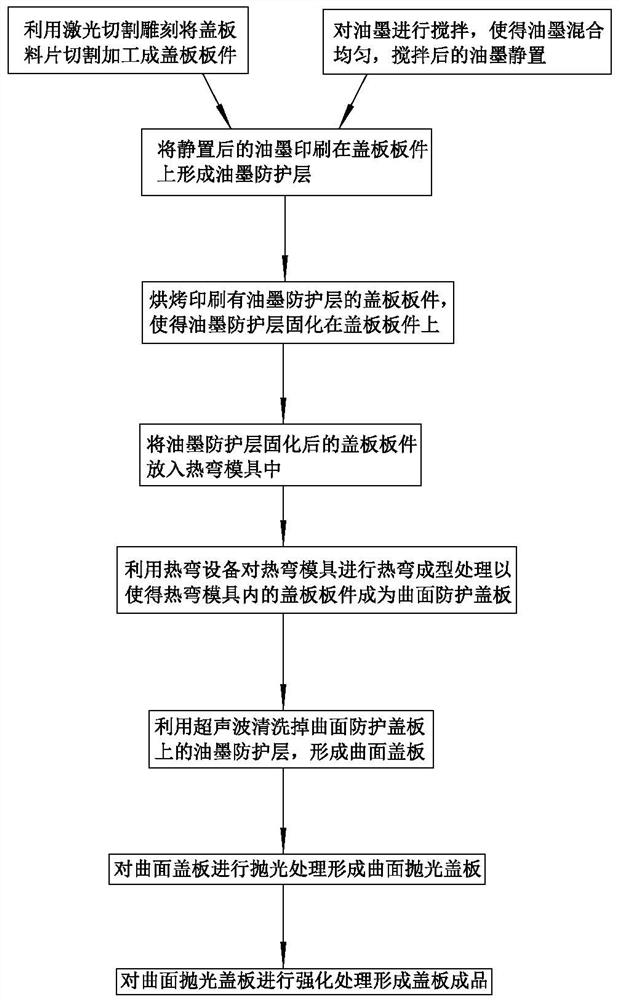

A molding process and cover plate technology, which is applied in the field of cover plate hot bending protection molding process, can solve the problems of low production efficiency of curved cover plates, high production and manufacturing of curved cover plates, and damage of cover plates, etc., so as to improve production and manufacturing. Yield, reduced imprinting, and the effect of lowering manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

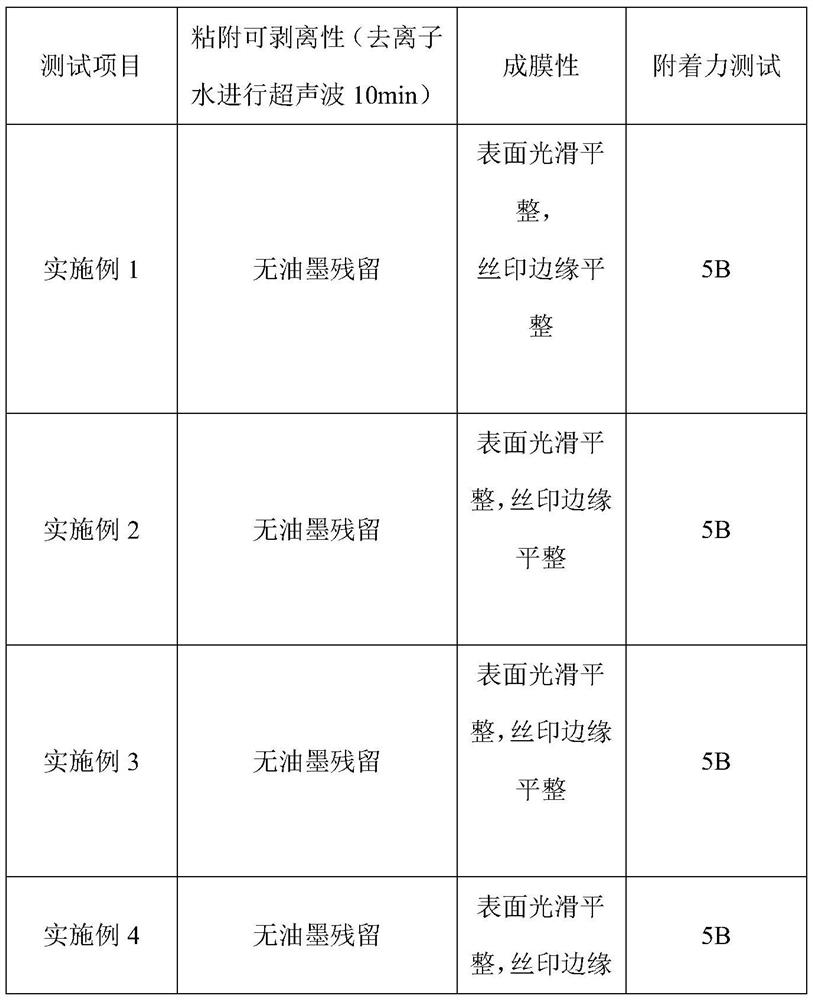

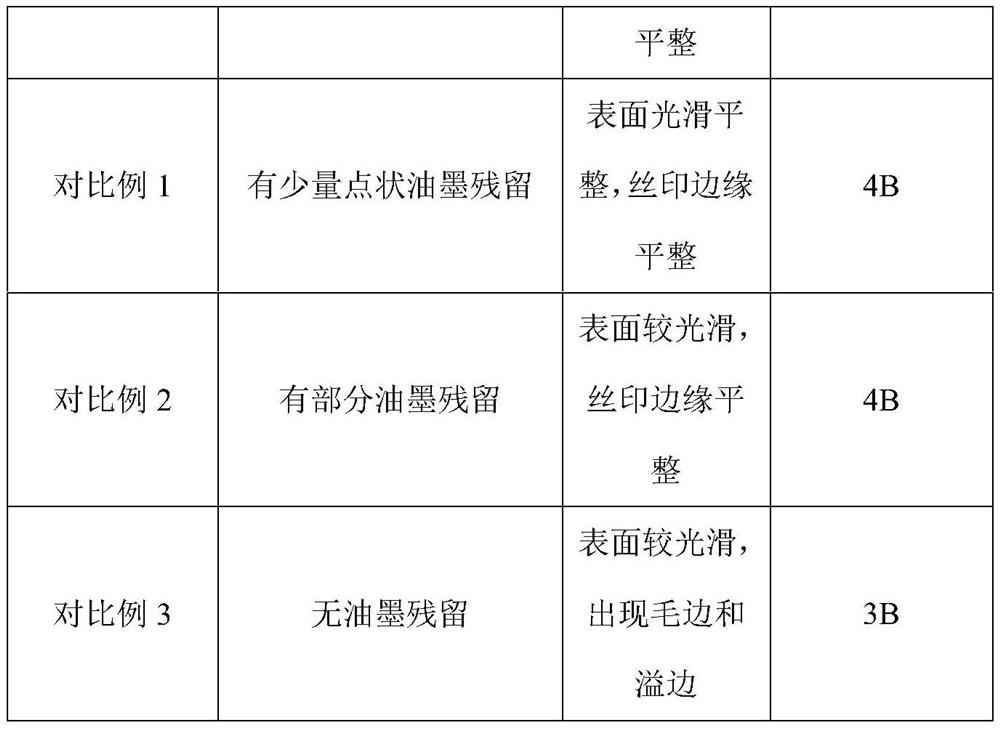

Embodiment 1

[0048] In this embodiment, the high temperature resistant protective ink includes the following raw materials in parts by weight: 38 parts of component A, 5 parts of silicon dioxide, 30 parts of calcium sulfate crystals, 2 parts of rutile titanium, 10 parts of PTFE, 13 parts of talcum powder, and leveling agent 1 part, 1 part of defoamer;

[0049] Each part of component A includes the following raw materials in parts by weight: 46 parts of modified acrylic resin, 24 parts of deionized water, 11 parts of absolute ethanol, 5 parts of butyl glycol ether, 0.4 part of organic acid, and 0.5 part of emulsifier , 4 parts of hydrogen peroxide.

[0050] Further, the leveling agent is composed of polyether-modified polysiloxane and polymethylphenylsiloxane in a mass ratio of 1:1.5. The polyether modified polysiloxane is preferably but not limited to BYK-333 leveling agent from Germany.

[0051] Further, the defoamer is composed of polydimethylsiloxane, fluorinated silicone oil and octy...

Embodiment 2

[0064] In this embodiment, the high temperature resistant protective ink includes the following raw materials in parts by weight: 36 parts of component A, 4 parts of silicon dioxide, 28 parts of calcium sulfate crystals, 1.6 parts of rutile titanium, 8 parts of PTFE, 11 parts of talcum powder, leveling 0.7 parts of agent, 1.3 parts of defoamer;

[0065] Each part of component A includes the following raw materials in parts by weight: 44 parts of modified acrylic resin, 22 parts of deionized water, 10 parts of absolute ethanol, 4 parts of butyl glycol ether, 0.2 part of organic acid, and 0.2 part of emulsifier , 1 part of hydrogen peroxide.

[0066] Further, the leveling agent is composed of polyether-modified polysiloxane and polymethylphenylsiloxane in a mass ratio of 1:0.8.

[0067] Further, the defoamer is composed of polydimethylsiloxane, fluorinated silicone oil and octylphenol polyoxyethylene ether in a weight ratio of 1:1:0.5. The organic acid is composed of cinnamic ...

Embodiment 3

[0080] In this embodiment, the high temperature resistant protective ink includes the following raw materials in parts by weight: 40 parts of component A, 6 parts of silicon dioxide, 32 parts of calcium sulfate crystals, 2.4 parts of rutile titanium, 12 parts of PTFE, 15 parts of talcum powder, leveling 1.2 parts of agent, 0.7 parts of defoamer;

[0081] Each part of component A includes the following raw materials in parts by weight: 48 parts of modified acrylic resin, 26 parts of deionized water, 12 parts of absolute ethanol, 6 parts of butyl glycol ether, 0.7 part of organic acid, and 0.8 part of emulsifier , 5 parts of hydrogen peroxide.

[0082] Further, the leveling agent is composed of polyether-modified polysiloxane and polymethylphenylsiloxane in a mass ratio of 1:2. The polyether modified polysiloxane is preferably but not limited to BYK-333 leveling agent from Germany.

[0083] Further, the defoamer is composed of polydimethylsiloxane, fluorinated silicone oil and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com