Variable valve transmission device of piston internal combustion engine

A technology for internal combustion engines and transmissions, applied to valve devices, engine components, machines/engines, etc., can solve the problems of inaccurate determination of oil film distribution, discontinuity of switching time, disadvantages, etc., and expand the available operating range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

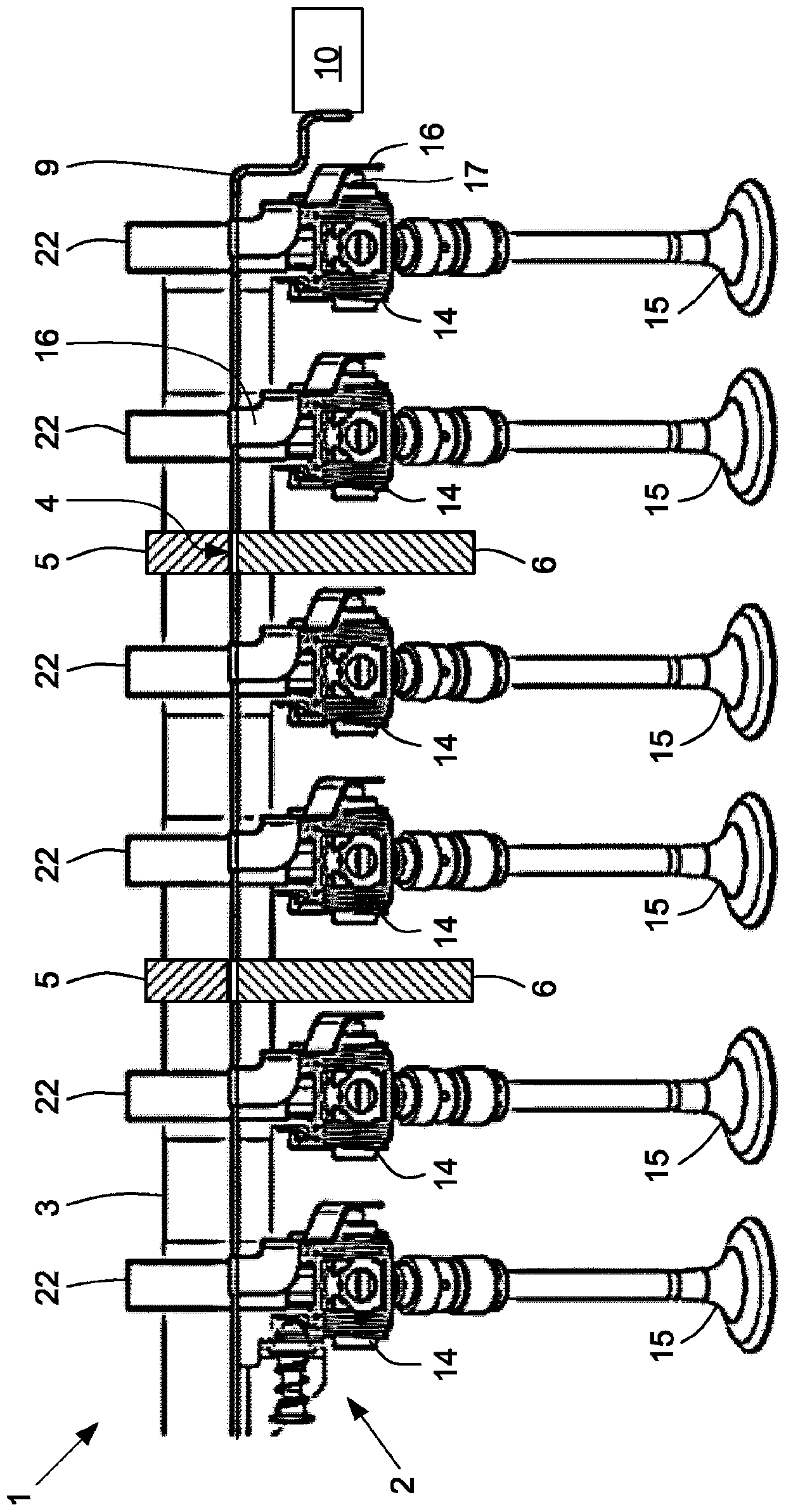

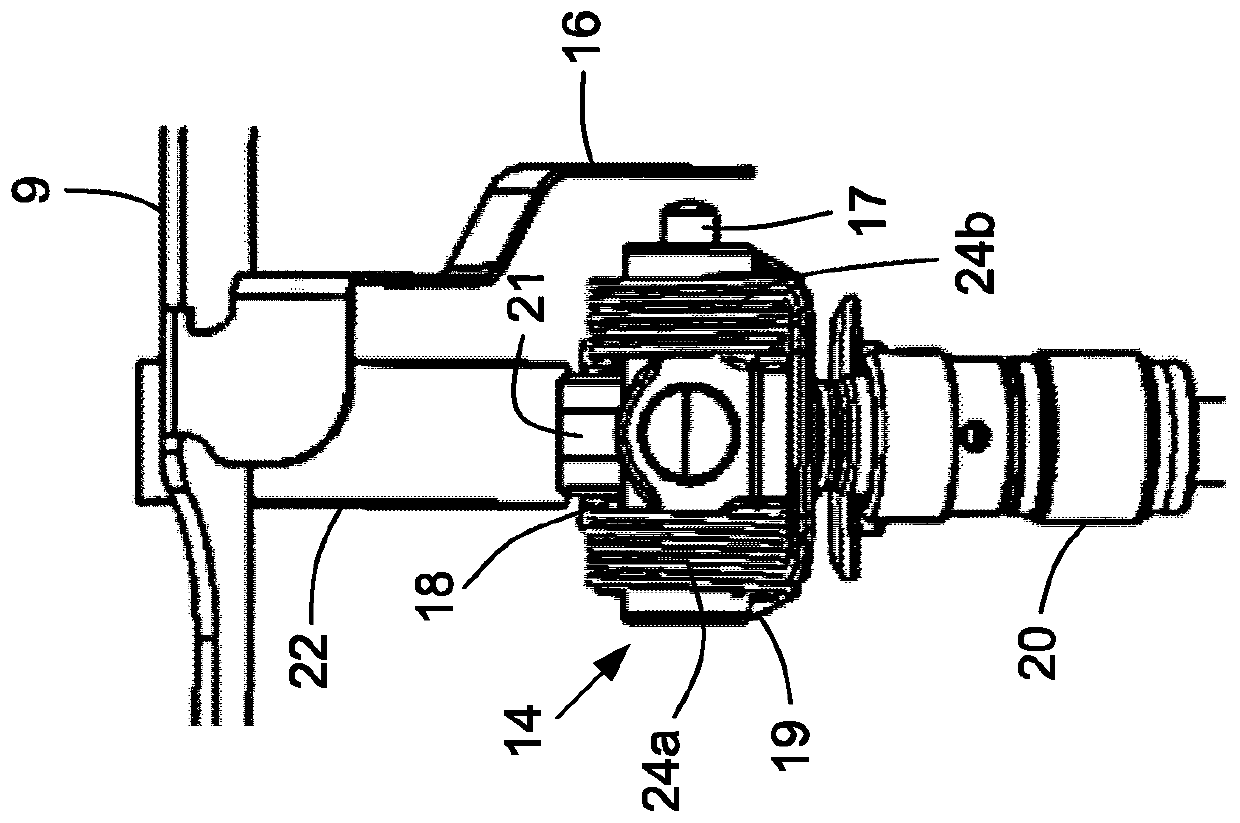

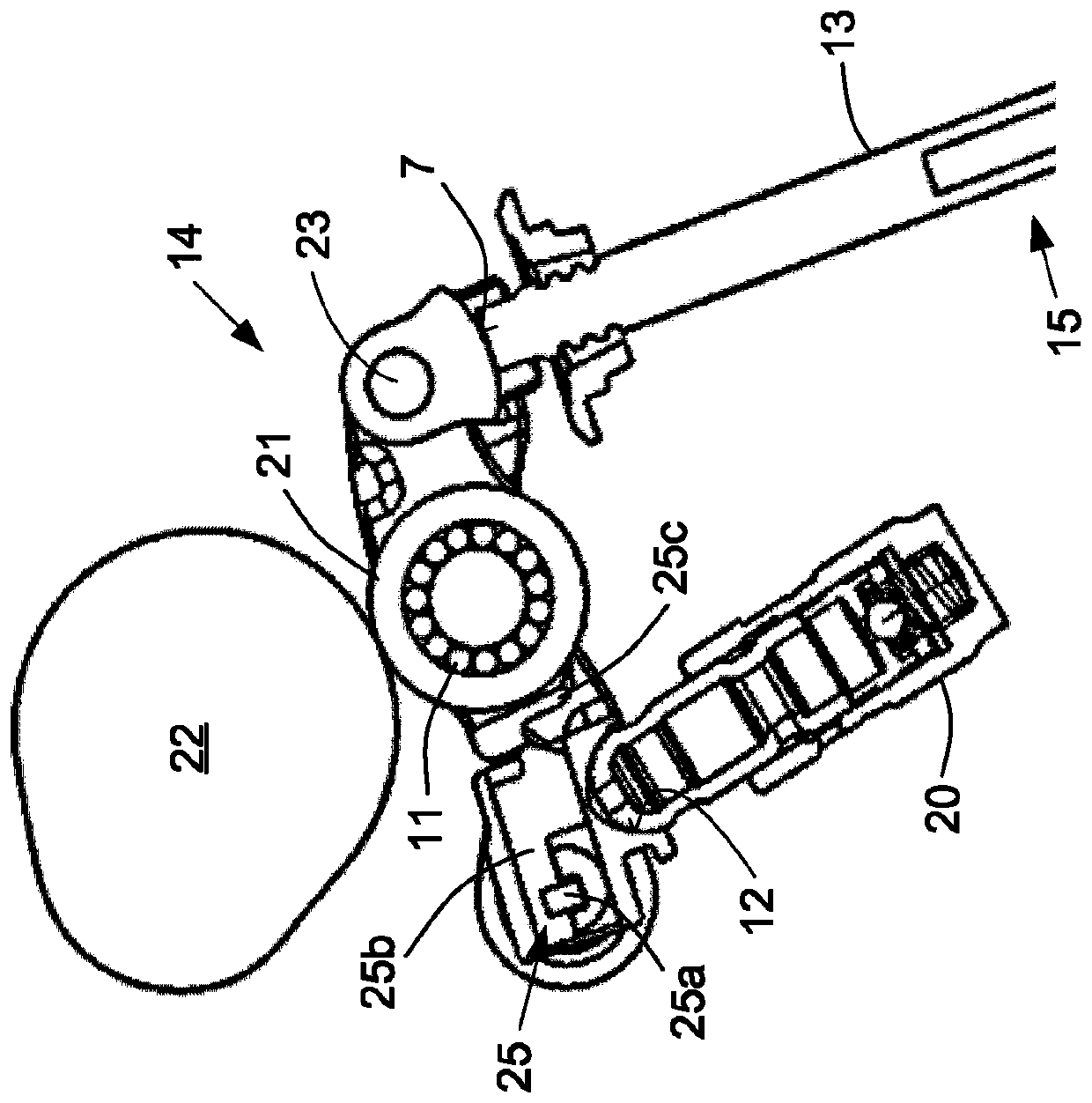

[0038] Thus, in figure 1 The cylinder head 1 of a hypothetical six-cylinder piston internal combustion engine shown in FIG. 1 has a variable valve gear 2 , each having twelve intake valves and twelve exhaust valves. The exhaust camshaft 3 is supported in the cylinder head 1 in a plurality, for example seven, of camshaft half bearing blocks 6 . In addition, several, for example seven, associated upper camshaft half-bearing caps 5 are fixedly screwed onto the parting plane 4 of the cylinder head 1 , which is also designed for accommodating a valve cover (not shown). Two camshaft half-bearing supports 6 and two camshaft half-bearing caps 5 respectively assigned to the camshaft half-bearing supports 6 are shown in an exemplary and schematically simplified manner at figure 1 shown in .

[0039] The upper camshaft half-bearing caps 5 each overlap a guide 8 arranged in the separating plane 4 as a recess in the camshaft half-bearing seat 6 , wherein the guides 8 configured as a rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com