Press-fitting equipment of washing machine barrel hoop

A washing machine drum and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inapplicability to small-batch production, lack of positioning of press-fitting equipment, and inability to meet assembly requirements, etc., to reduce repair and maintenance costs Low cost, simple structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

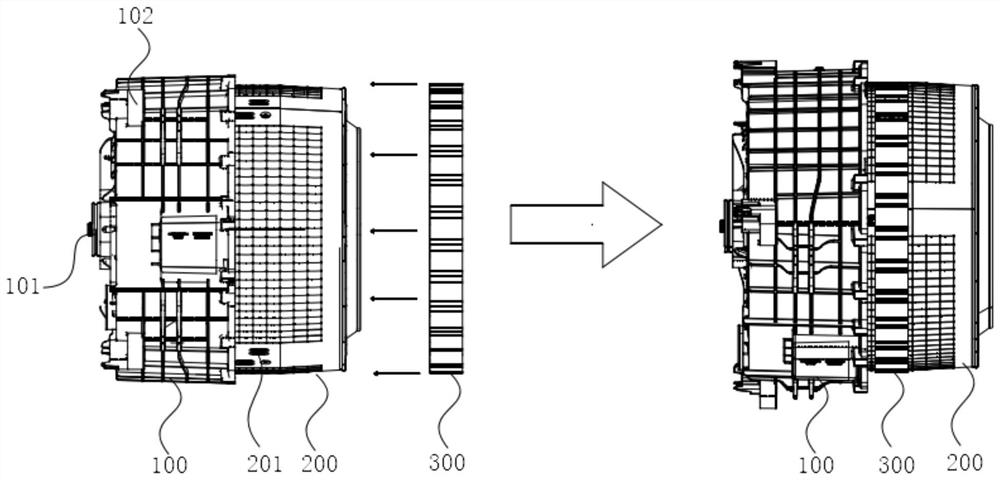

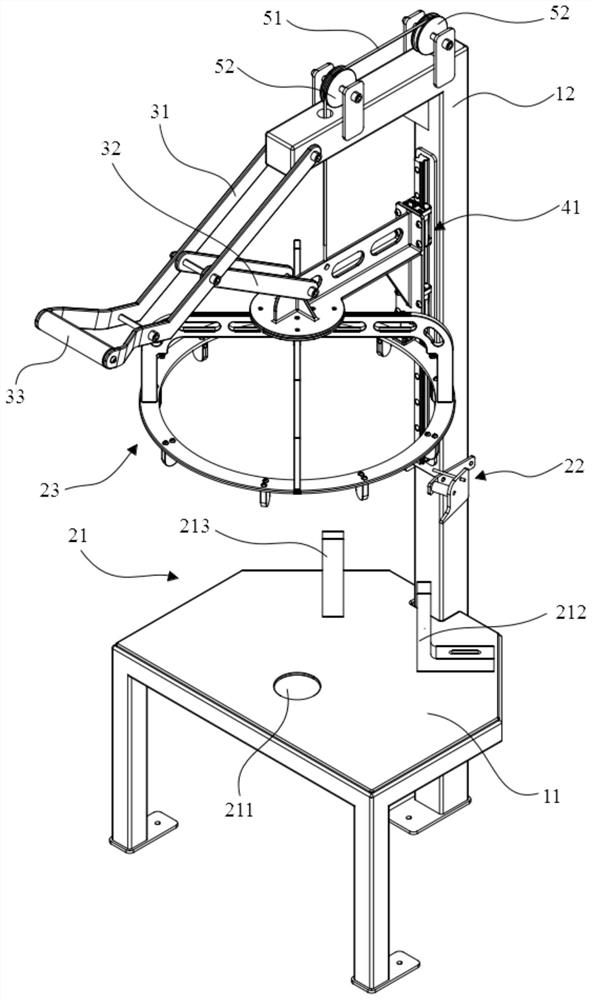

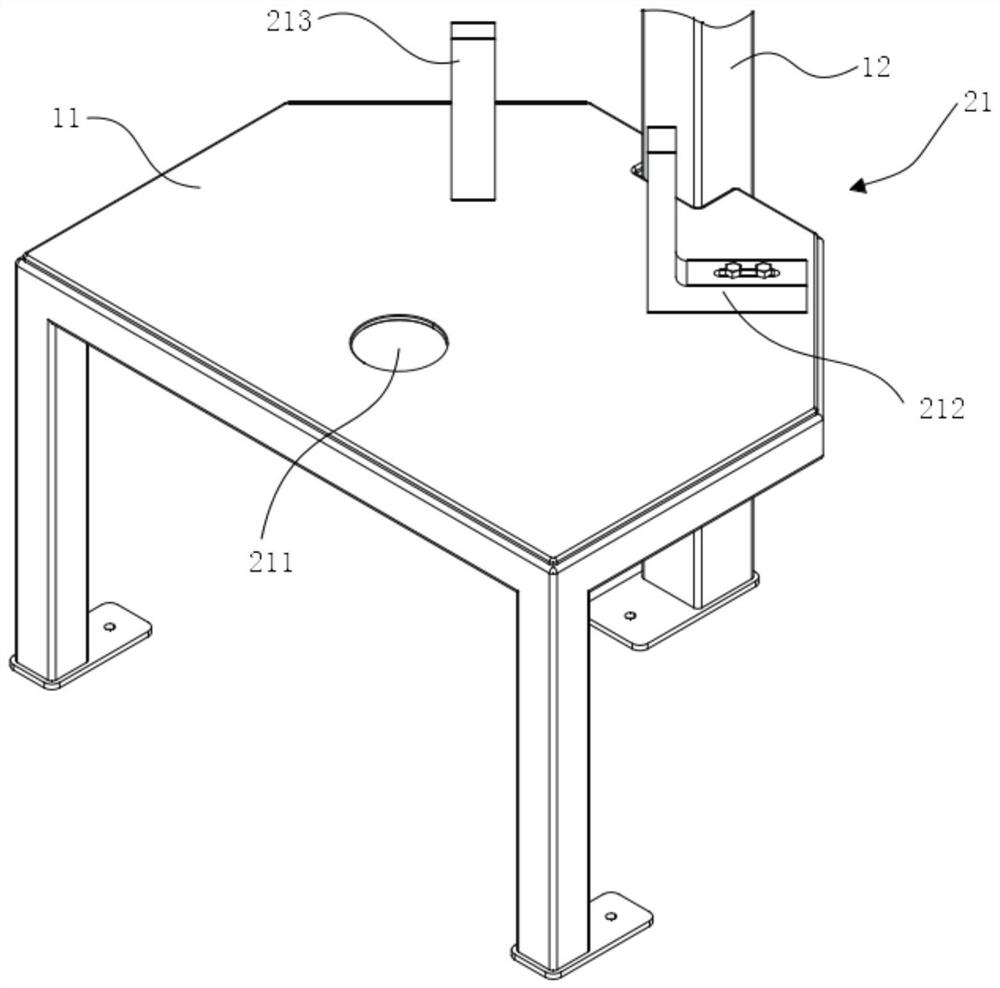

[0040] like Figure 2-Figure 6 As shown, this embodiment provides a washing machine tub hoop press-fitting device, which is used to press-fit the tub hoop 300 onto the inner tub 200 of the washing machine tub assembly. The hoop press-fitting equipment includes a frame, a positioning device and a press-fitting device. Frame is used for supporting whole body, and it comprises the workbench 11 that is arranged in horizontal direction and the support frame 12 that is provided with in vertical direction, and support frame 12 of present embodiment is located at the side of workbench 11, and with workbench 11 Fixed connection. The positioning device includes an outer cylinder positioning device 21, an inner cylinder positioning device 22 and a cylinder hoop positioning device 23, wherein the outer cylinder positioning device 21 is installed on the workbench 11 to limit the horizontal position and axial rotation of the outer cylinder 100 , the inner cylinder positioning device 22 is...

Embodiment 2

[0053] This embodiment provides another washing machine drum hoop pressing device, including a frame, a positioning device, a pressing device and a guiding device 41, wherein the structure of the frame, positioning device, and guiding device 41 is the same as that in Embodiment 1, here No more details, the difference between this embodiment and Embodiment 1 is that the press-fitting device of this embodiment adopts an automatic press-fitting method.

[0054] The press-fitting device of this embodiment includes a driving mechanism, the driving mechanism is fixed on the top of the support frame 12, and the output end of the driving mechanism is connected with the top plate 231 of the cylinder hoop positioning device 23, and the cylinder hoop positioning device 23 is driven to move up and down by the driving mechanism, thereby The barrel collar 300 is press fitted onto the inner barrel 200 of the barrel assembly. Specifically, the driving device may be a mechanism such as an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com