Convenient-to-move wall paint spraying device

A kind of painting equipment and surface fixing technology, which is applied in the direction of painting booth, spraying device, pretreatment surface, etc., can solve the problems of small painting range and poor stability, and achieve the effect of improving painting efficiency, solving poor stability and preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

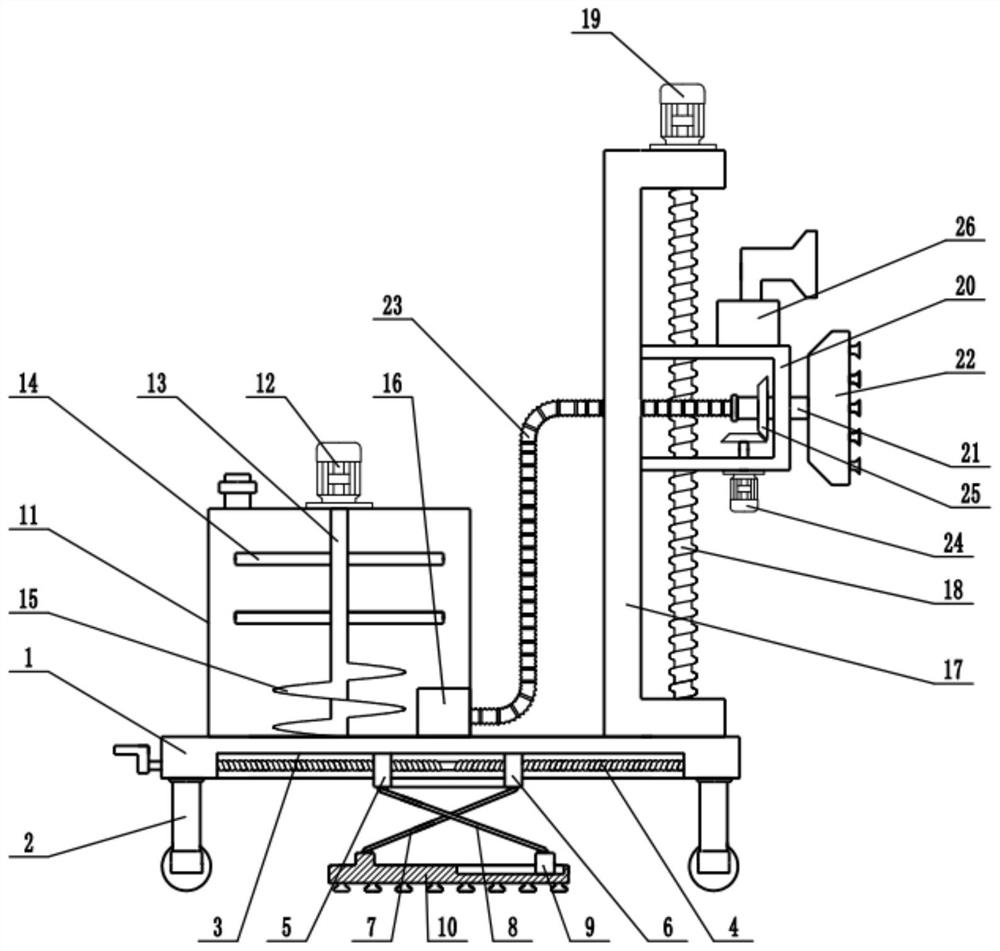

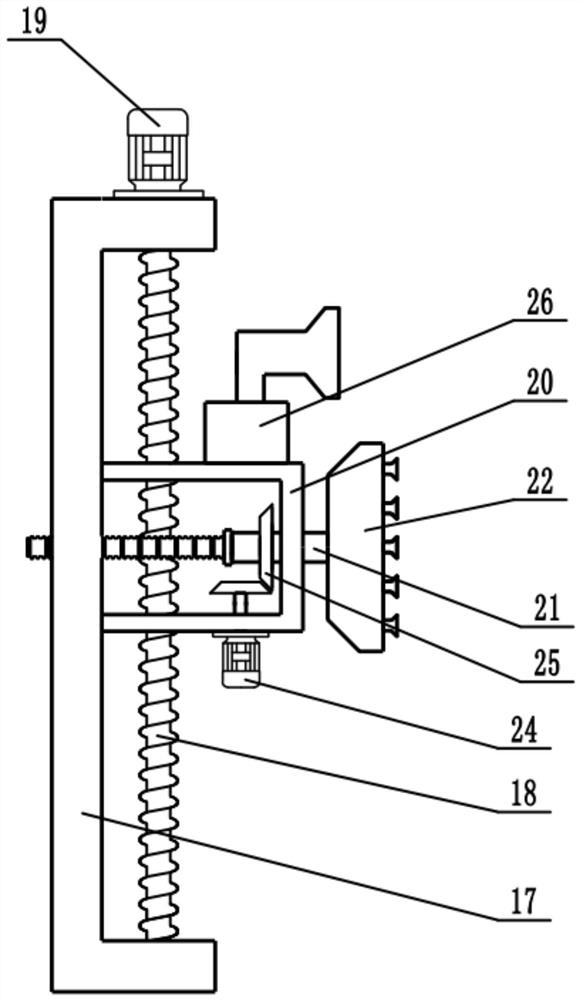

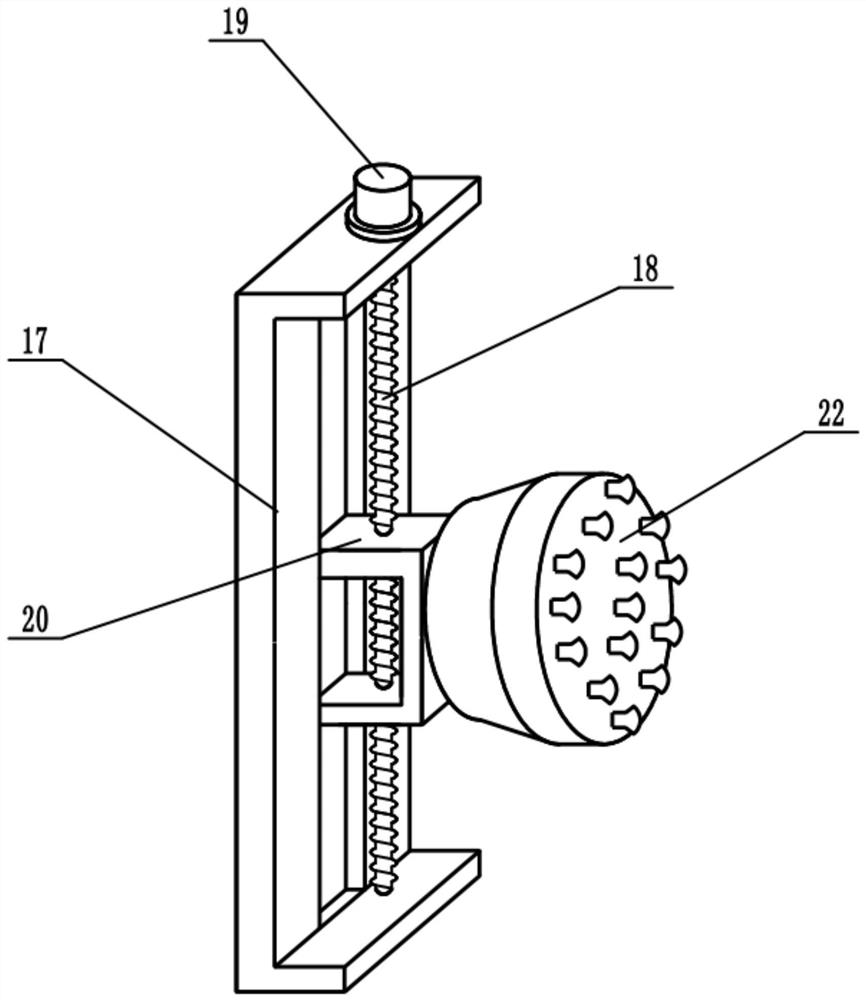

[0022] see Figure 1-3 , in the embodiment of the present invention, a kind of wall surface painting equipment that is convenient to move, comprises frame 1, material storage box 11, booster pump 16, installation frame 17 and nozzle 22, and the bottom of frame 1 is equipped with universal wheel 2 , to facilitate the movement of the device, the upper surface of the frame 1 is fixedly connected with a storage box 11 for storing paint, the inside of the storage box 11 is equipped with a stirring mechanism, the stirring mechanism includes a first motor 12, a stirring shaft 13, Stirring rod 14, spiral plate 15, the top of material storage box 11 is fixedly connected with first motor 12, and the axle extension end of first motor 12 is fixedly connected with stirring shaft 13, and stirring shaft 13 stretches in the material storage box 11, and stirring shaft Stirring rods 14 are distributed on the 13, and a spiral plate 15 is installed on the lower end of the stirring shaft 13. The f...

Embodiment 2

[0024] On the basis of Embodiment 1, a stabilizing mechanism is installed on the bottom of the frame 1, and the stabilizing mechanism includes a two-way screw rod 4, a left slider 5, a right slider 6, a first support rod 7, a second support rod 8, a sliding Block 9 and support plate 10, the bottom of frame 1 is provided with chute 3, and the inside of chute 3 is equipped with two-way screw mandrel 4, and the two ends of two-way screw mandrel 4 are rotationally connected with the side wall of chute 3, two-way screw mandrel 4. The upper sleeve is provided with a left slider 5 and a right slider 6. The left slider 5 and the right slider 6 are threadedly connected with the two-way screw rod 4 respectively. The left slider 5 and the right slider 6 are embedded in the chute 3 respectively. The slider 5 and the right slider 6 are slidably connected with the chute 3 respectively, the left slider 5 and the right slider 6 can slide left and right in the chute 3, the end of the two-way sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com